Technology for manufacturing ultra-micro semiconductor cooling device

A manufacturing process and semiconductor technology, which is applied in the field of manufacturing process of ultra-micro semiconductor refrigeration devices, can solve the problems that the manufacturing process cannot meet the requirements of manufacturing ultra-micro semiconductor refrigeration devices, and achieve high efficiency, accurate operation, and avoidance of damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

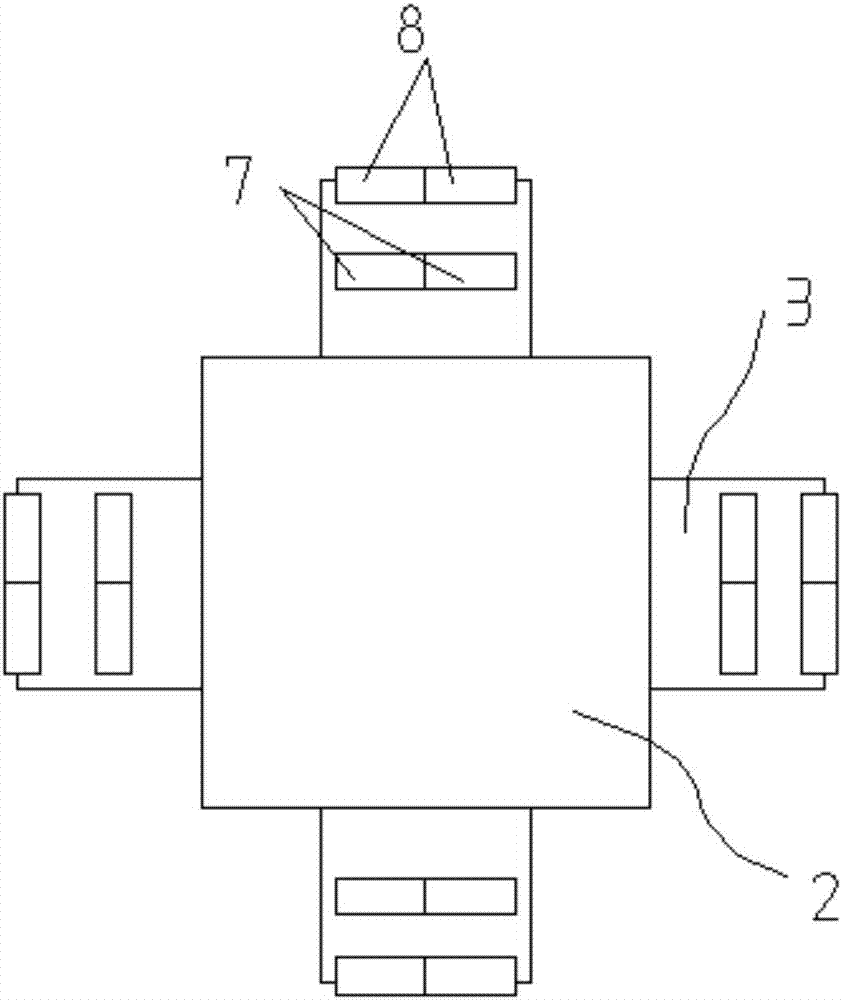

Image

Examples

Embodiment Construction

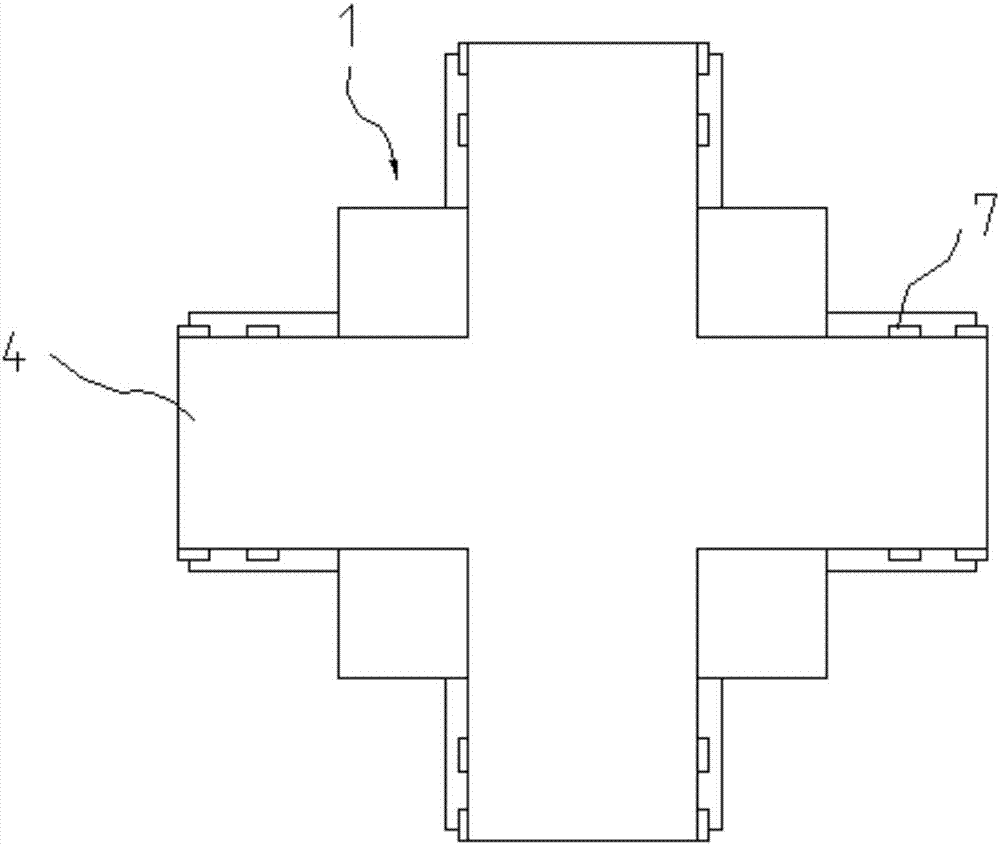

[0040] The manufacturing process of semiconductor refrigeration ultra-miniature devices provided in this embodiment includes the following steps,

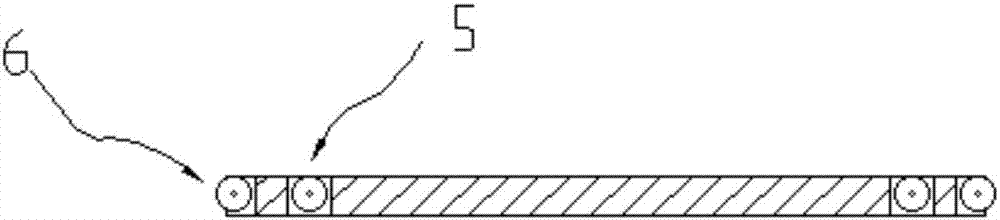

[0041] Step 1: Preparation of crystal grains, the cutting is completed, and the coated wafers are bonded to the blue film using a chip bonder, and the dicing machine is used to complete the cutting according to the required grain size, and the blue film is cut using a film expander. The film and the grains attached to it are extended to the mold;

[0042] Step 2: Arrangement of crystal grains, install the mold with expanded grains on the material rack of the chip placement machine, place the ceramic chips with solder paste printed on the workbench, and make the chips on the chip placement machine according to the designed grain arrangement rules. The suction head can pick up the grain and place it on the designated position of the tile;

[0043] Step 3: Welding of tiles and crystal grains. First, absorb one end of the tiles on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com