Zinc bismuth tellurium heterogeneous phase change nanowire material and its preparation method and application

A nanowire and phase transition technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of not satisfying one-dimensional device assembly and testing, different composition and application scope, etc. Achieving good phase change storage performance, conducive to market-oriented applications, and the effect of fewer operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

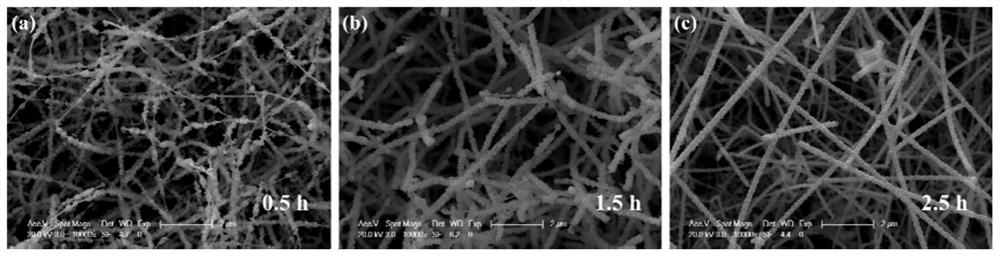

Embodiment 1

[0029] 1. Clean SiO2 2 / / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities:

[0030] (a) Place the substrate in an ethanol solution, and clean it ultrasonically for 15 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0031] (b) The substrate is placed in an acetone solution, and ultrasonically cleaned for 15 minutes to remove organic impurities on the surface of the substrate;

[0032] (c) Place the substrate in deionized water, clean it ultrasonically for 15 minutes, and clean the surface again;

[0033] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0034] 2. Preparation of sputtered gold coating by sputtering method

[0035](a) Put the Au simple substance target, install the substrate, and then seal the vacuum chamber

[0036] (b) Turn on the gas flow meter for 5 minutes, then put it in the valve control state, turn on the mechanical pump to vacuum, when the v...

Embodiment 2

[0048] 1. Clean SiO2 2 / / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities:

[0049] (a) Place the substrate in an ethanol solution, and clean it ultrasonically for 15 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0050] (b) The substrate is placed in an acetone solution, and ultrasonically cleaned for 15 minutes to remove organic impurities on the surface of the substrate;

[0051] (c) Place the substrate in deionized water, clean it ultrasonically for 15 minutes, and clean the surface again;

[0052] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0053] 2. Preparation of sputtered gold coating by sputtering method

[0054] (a) Put the Au simple substance target, install the substrate, and then seal the vacuum chamber

[0055] (b) Turn on the gas flow meter for 5 minutes, then put it in the valve control state, turn on the mechanical pump to vacuum, when the ...

Embodiment 3

[0067] 1. Clean SiO2 2 / / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities:

[0068] (a) Place the substrate in an ethanol solution, and clean it ultrasonically for 15 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0069] (b) The substrate is placed in an acetone solution, and ultrasonically cleaned for 15 minutes to remove organic impurities on the surface of the substrate;

[0070] (c) Place the substrate in deionized water, clean it ultrasonically for 15 minutes, and clean the surface again;

[0071] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0072] 2. Preparation of sputtered gold coating by sputtering method

[0073] (a) Put the Au simple substance target, install the substrate, and then seal the vacuum chamber

[0074] (b) Turn on the gas flow meter for 5 minutes, then put it in the valve control state, turn on the mechanical pump to vacuum, when the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com