Functional composite film and wavelength conversion film

A technology of wavelength conversion and composite film, which is applied in the direction of nonlinear optics, synthetic resin layered products, and optical elements used to change the spectral characteristics of emitted light. Hardness, good handleability, and the effect of preventing the decrease of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0348]

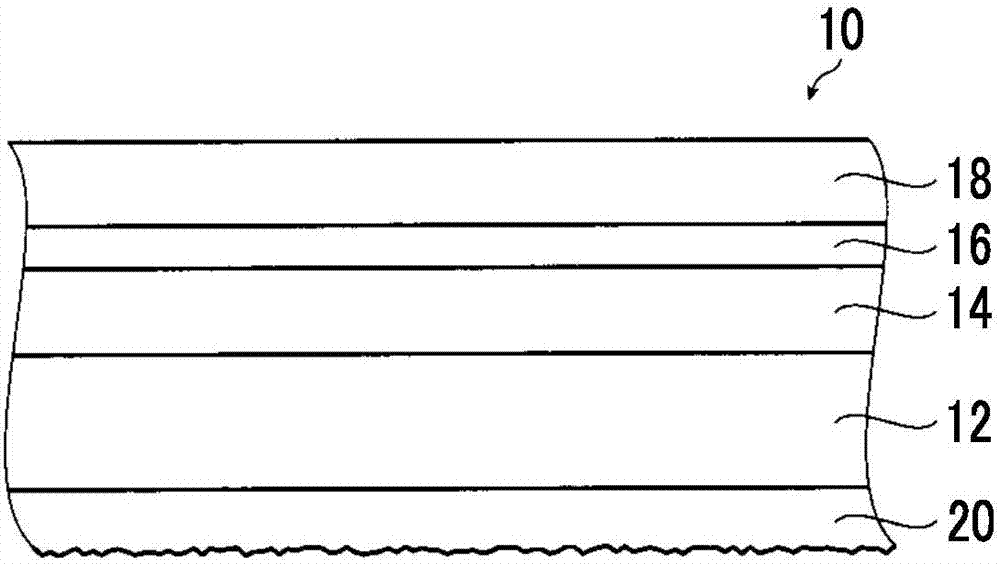

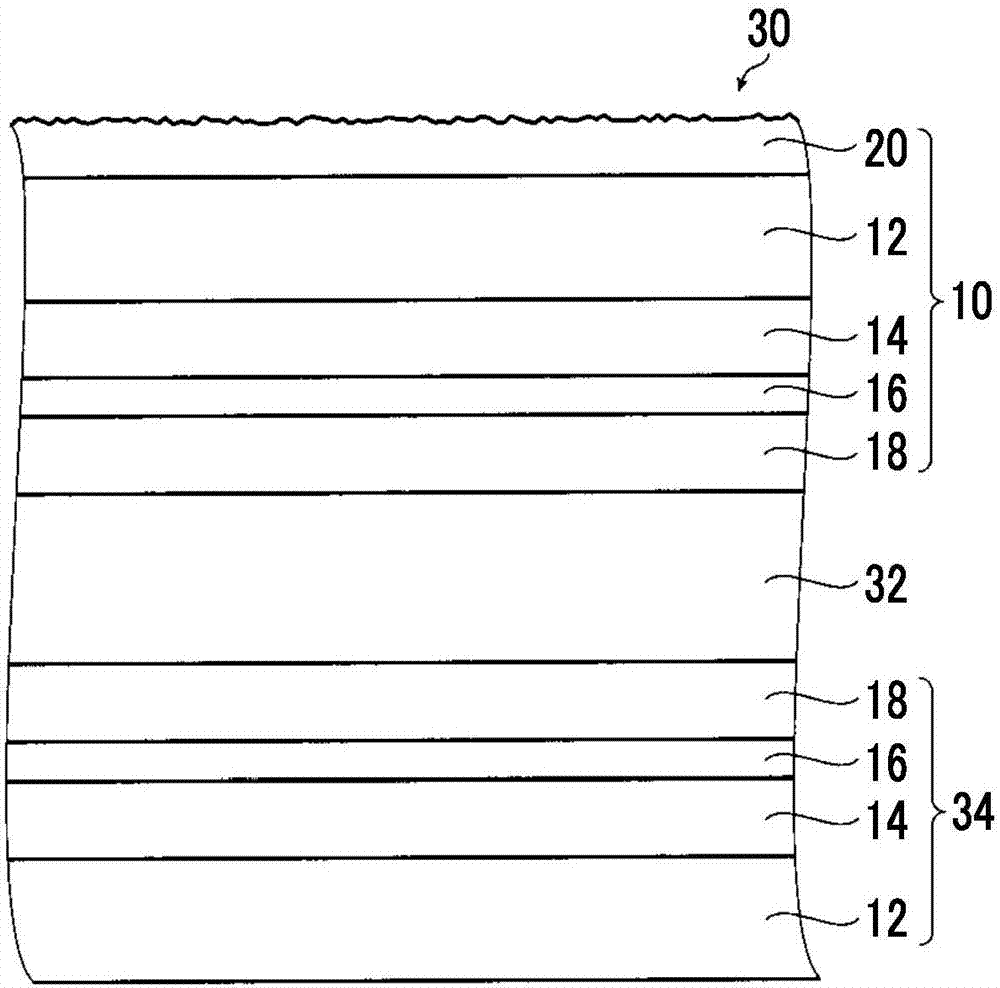

[0349] A gas barrier film having a base organic layer 14 , an inorganic layer 16 , and a light diffusion layer 20 was formed on the support body 12 . That is, the gas barrier film has the same figure 1 and figure 2 The gas barrier film 10 shown is a gas barrier film of the same structure.

[0350] And the gas barrier film was produced in the same manner except not forming the light-diffusion layer 20 . That is, this gas barrier film is also a gas barrier film having the same structure as the gas barrier film 34 shown in FIG. 3 except that it does not have the adhesive layer 18 .

[0351] The support body 12 used a PET film (COSMOSHINE A4300 manufactured by Toyobo Co., Ltd.) having a width of 1000 mm, a thickness of 50 μm, and a length of 100 m.

[0352] >

[0353] Prepare TMPTA (manufactured by Daicel-Cytec Company, Ltd.) and photopolymerization initiator (manufactured by Lamberti S.p.A, ESACURE KTO46), weigh them so that the mass ratio becomes 95:5, and dissol...

Embodiment 2

[0378] As the adhesive, in addition to using ACRIT 8BR930 manufactured by Taisei Fine Chemical Co., Ltd., ACRIT 8UX-015A manufactured by Taisei Fine Chemical Co., Ltd. was used, and the same method as in Example 1 was used. Method A coating composition to be the light-diffusing layer 20 was prepared. Moreover, the quantity of the binder in the coating composition used as the light-diffusion layer 20 was made into the same quantity as Example 1, and the mass ratio of ACRIT 8BR930 and ACRIT 8UX-015A was 15:85.

[0379] ACRIT 8UX-015A added to the adhesive is a UV curable urethane acrylate with a weight average molecular weight of 1000-2000.

[0380] A gas barrier film was produced in the same manner as in Example 1 except that the light-diffusing layer 20 was formed using this coating composition. And, except that this gas barrier film was used, a wavelength conversion film was produced in the same manner as in Example 1.

[0381] As a result of measuring the refractive index ...

Embodiment 3

[0383] As the adhesive, in addition to using ACRIT 8BR930 manufactured by Taisei Fine Chemical Co., Ltd., ACRIT 8DK-3000 manufactured by Taisei Fine Chemical Co., Ltd. was also used. Method A coating composition to be the light-diffusing layer 20 was prepared. Moreover, the quantity of the binder in the coating composition used as the light-diffusion layer 20 was made into the same quantity as Example 1, and the mass ratio of ACRIT 8BR930 and ACRIT 8DK-3000 was 15:85.

[0384] ACRIT 8DK-3000 added to the adhesive is an ultraviolet curable acrylic polymer with a weight average molecular weight of 5000 and a double bond equivalent of 400 g / mol.

[0385] Except having formed the light-diffusion layer 20 using this coating composition, it carried out similarly to Example 1, and produced the gas barrier film. And, except that this gas barrier film was used, a wavelength conversion film was produced in the same manner as in Example 1.

[0386] As a result of measuring the refracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| double bond equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com