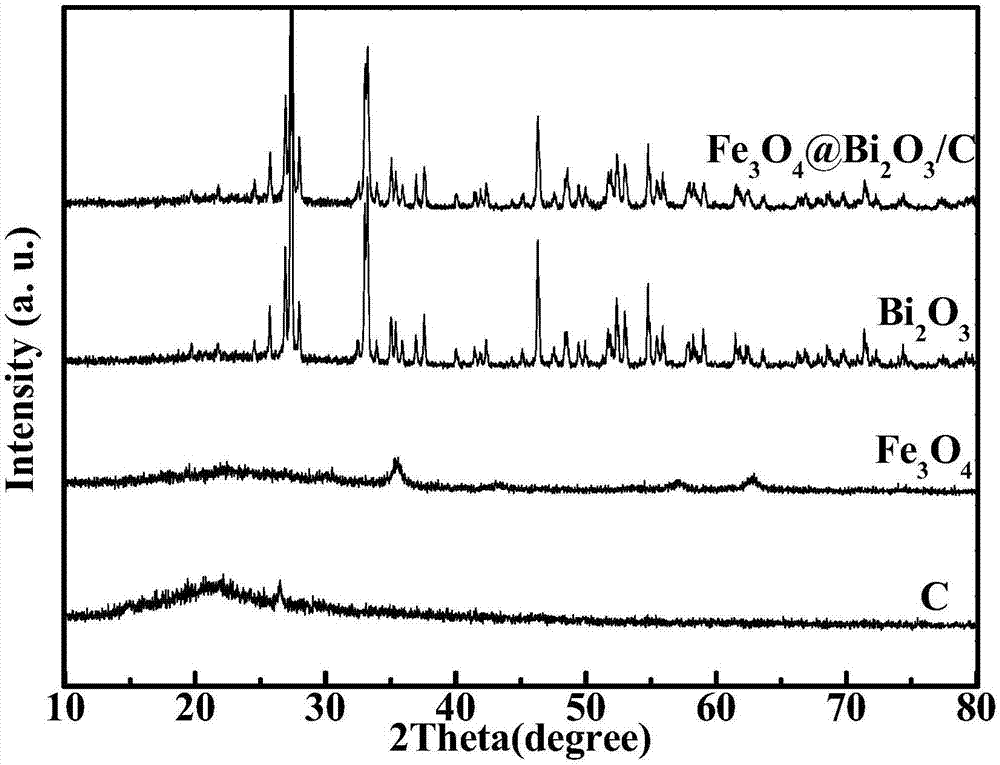

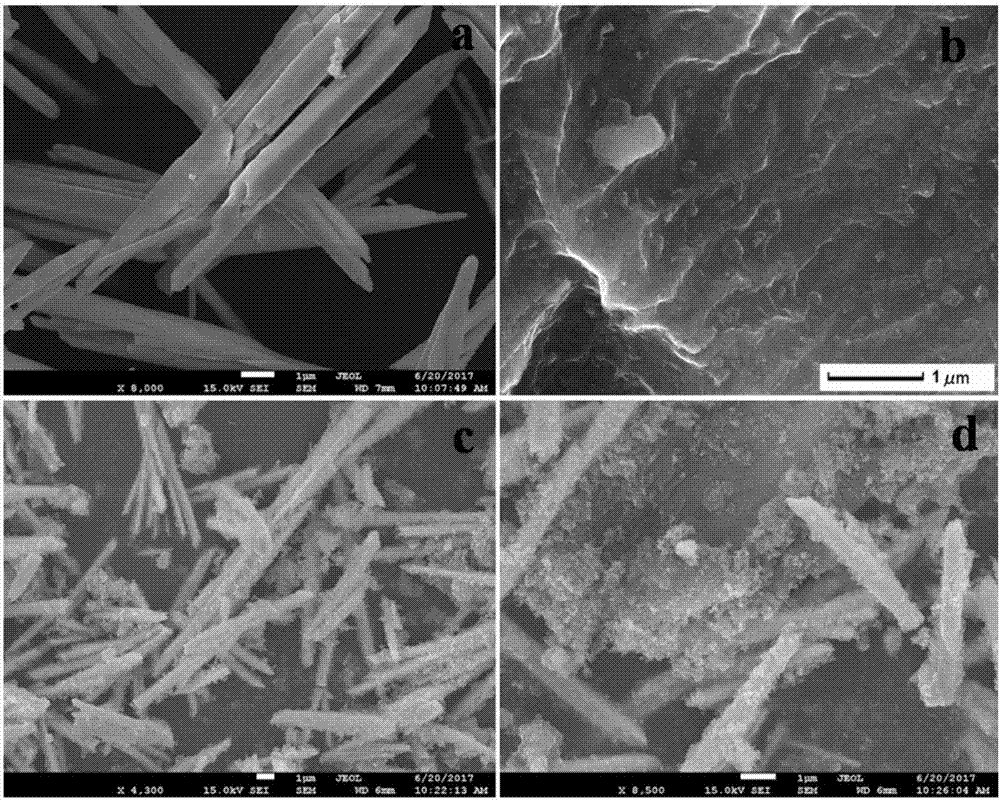

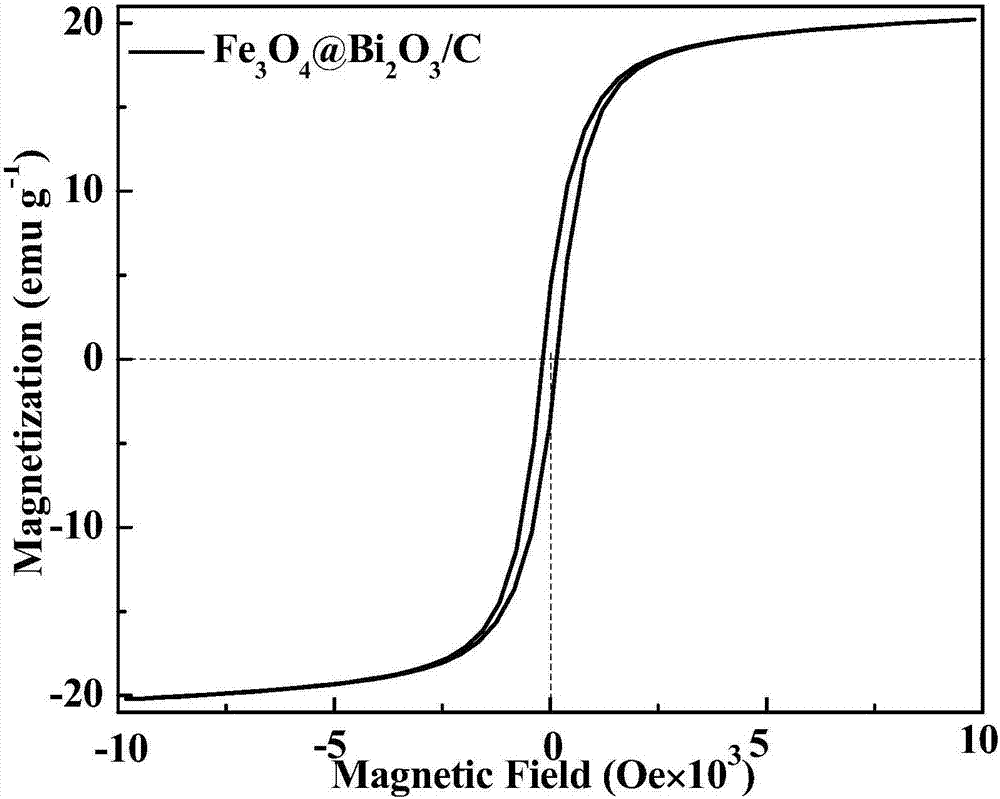

Biomass charcoal based magnetic bismuth oxide composite photocatalyst preparation method and application

A biomass carbon, bismuth oxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve application limitations, non-recyclability, and low light utilization rate and other problems, to achieve the effect of speeding up the transfer, convenient separation and recovery, and improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In step 1, Bi(NO 3 ) 3 ·5H 2 The amount of O is 0.9702g, the amount of deionized water is 40ml, the amount of anhydrous sodium sulfate is 0.4261g, and the mass of NaOH is 0.72g. The microwave reaction temperature is 80°C, the power is 1000W, and the reaction time is 15min.

[0038] In step 2, the amount of petal powder is 1g, the hydrothermal reaction temperature is 200°C, and the reaction time is 5h.

[0039] In step 3, in step 3, FeCl 2 ·4H 2 O and FeCl 3 ·6H 2 The dosage of O is 0.0707g and 0.01838g, and the dosage of ammonia is 5mL.

[0040] In step 4, the amount of C is 0.1 g, and the stirring reaction time is 20 min.

[0041] In step 1, step 2, step 4, the drying temperature of the sample is 60 ℃

Embodiment 2

[0043] In step 1, Bi(NO 3 ) 3 ·5H 2 The dosage of O is 1.9404g, the dosage of anhydrous sodium sulfate is 0.8522g, and the dosage of NaOH is 1.44g. The microwave reaction temperature is 80°C, the power is 500W, and the reaction time is 30min.

[0044] In step 2, the dosage of withered peach flower petal powder is 5g, the hydrothermal reaction temperature is 180°C, and the reaction time is 10h.

[0045] In step 3, FeCl 2 ·4H 2 O and FeCl 3 ·6H 2 The dosage of O is 0.703g and 0.1838g, and the dosage of ammonia is 10ml.

[0046] In step 4, the amount of biomass charcoal added was 0.5 g, and the stirring reaction time was 40 min.

[0047] In step 1, step 2, step 4, the drying temperature of the sample is 60 ℃

Embodiment 3

[0049] In step 1, Bi(NO 3 ) 3 ·5H 2 The amount of O is 1.4553g, the amount of deionized water is 40ml, the amount of anhydrous sodium sulfate is 0.6392g, and the mass of NaOH is 1.44g.

[0050] In step 1, the microwave reaction temperature is 80° C., the power is 800 W, and the reaction time is 20 min.

[0051] In step 2, the amount of petal powder is 3g, the hydrothermal reaction temperature is 190°C, and the reaction time is 8h.

[0052] In step 3, in step 3, FeCl 2 ·4H 2 O and FeCl 3 ·6H 2 The dosage of O is 0.1406g and 0.03676, respectively, and the dosage of ammonia is 8ml.

[0053] In step 4, the amount of C is 0.3 g, and the reaction time is 30 min.

[0054] In step 1, step 2, step 4, the drying temperature of the sample is 60 ℃

[0055] Evaluation of photocatalytic activity: In the DW-01 photochemical reaction instrument, irradiated with a visible light lamp, 100ml of 20mg L -1 Tetracycline simulated wastewater is added to the reactor and its initial value is measured, then the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com