Method and device for dehydrating kitchen waste wet material

A technology for kitchen waste and wet materials, which is applied in the field of dewatering methods and devices for kitchen waste wet materials, can solve the problems of kitchen waste pollution, surrounding environment pollution, inability to guarantee, etc. that are not solved from the source, so as to prevent environmental pollution or disease. The effect of spreading, avoiding secondary pollution, and preventing re-spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

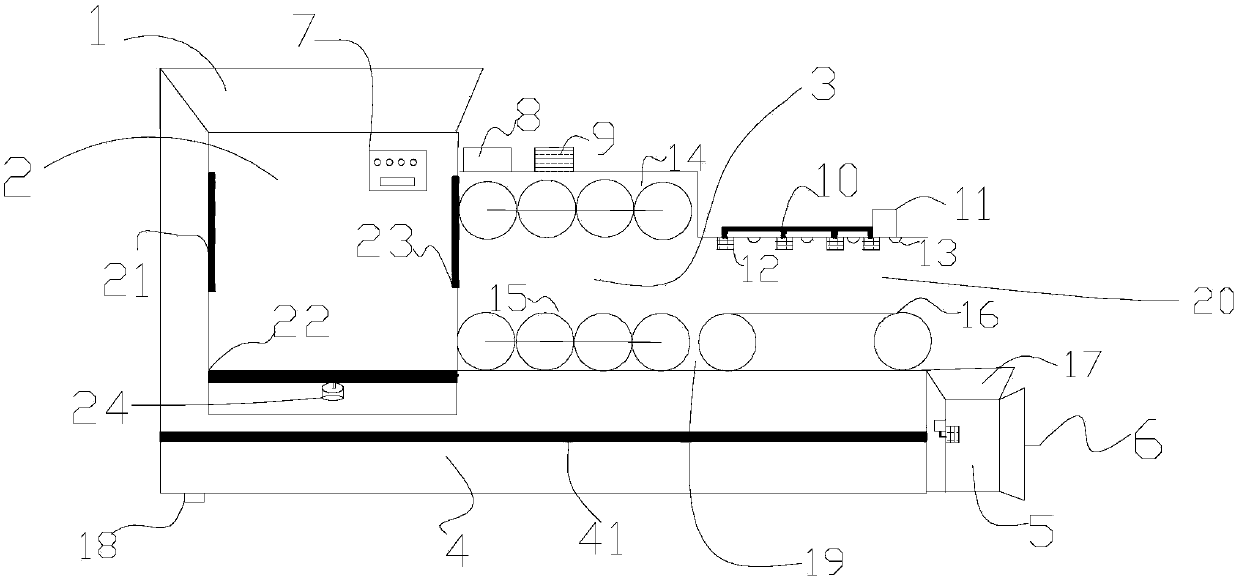

[0045] Such as figure 1 As shown, a method for dehydrating kitchen waste wet material comprises the following steps:

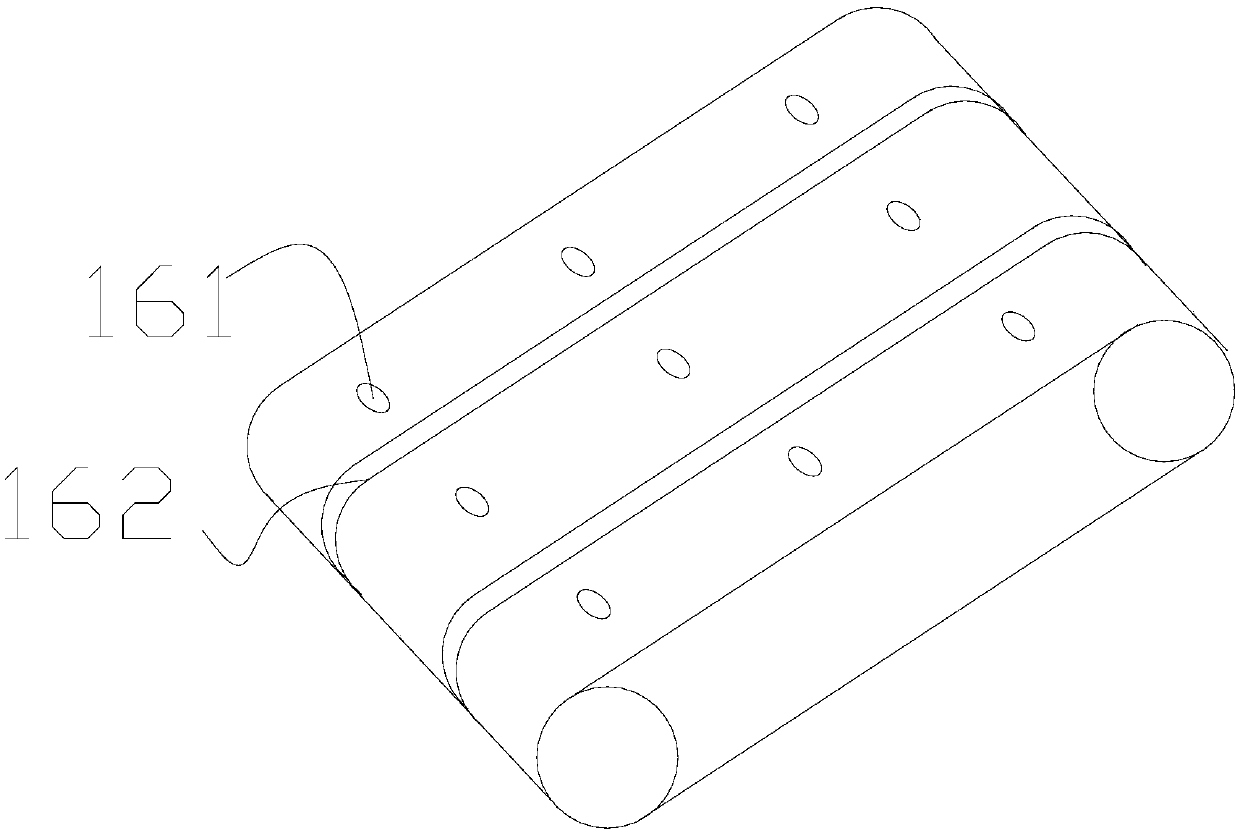

[0046] a. Pour the kitchen waste wet material to be processed into the centrifugal filter barrel 2 from the inlet 1. The barrel wall of the centrifugal filter barrel 2 has a plurality of filter mesh holes, and a part of the water in the kitchen waste wet material seeps through the filter mesh holes. out, and flow along the outer wall of the centrifugal filter barrel 2 through the filter plate 41 into the liquid collection chamber, and then discharge through the drain port 18;

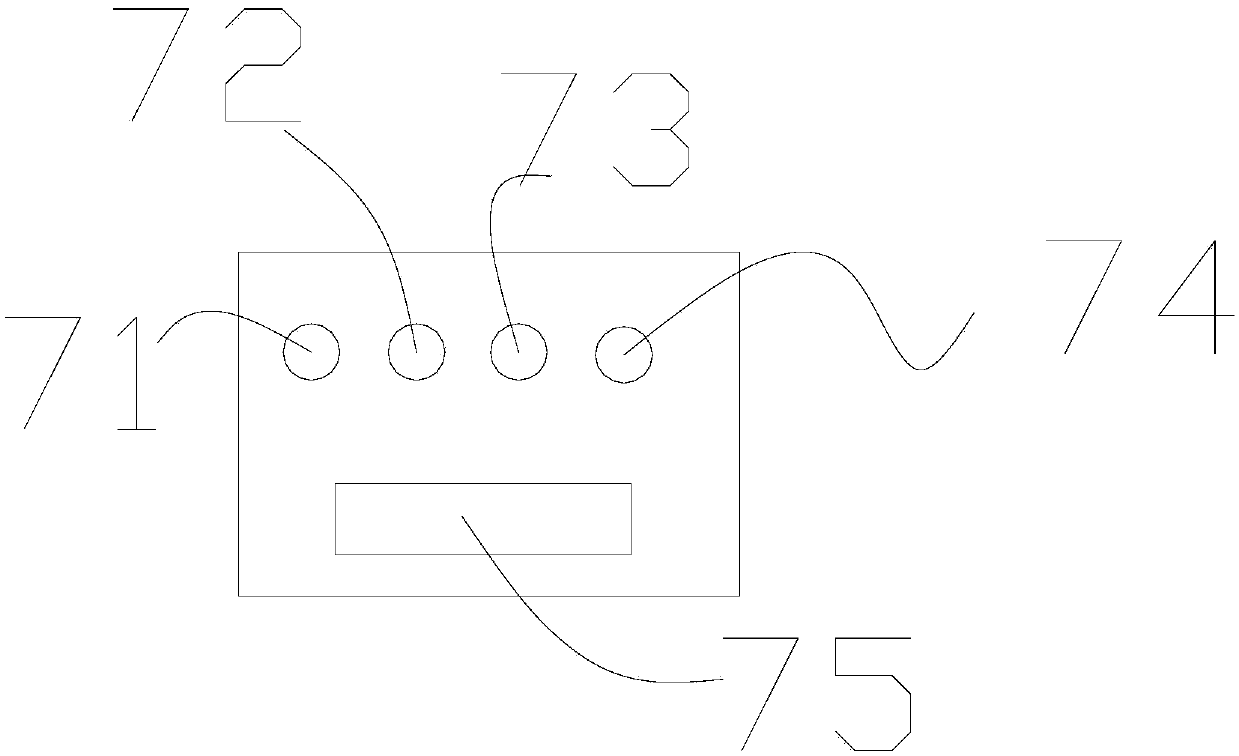

[0047] b. Rotate the start knob 71 of the centrifuge to set the drying time of the centrifuge, and the centrifugal filter bucket 2 equipped with wet food waste will rotate quickly to dry the wet food by centrifugal force; when the centrifuge 24 stops rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com