Magnesium-aluminum-zirconium composite brick with low thermal conductivity and preparation method thereof

A composite brick and magnesium-aluminum technology, applied in the field of refractory materials, can solve the problems of high porosity of low-conductivity magnesium-aluminum-zirconium composite bricks, deformation of the rotary kiln shell, and small thermal conductivity, etc., to achieve low thermal conductivity, good social benefits and Economic benefit and small thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

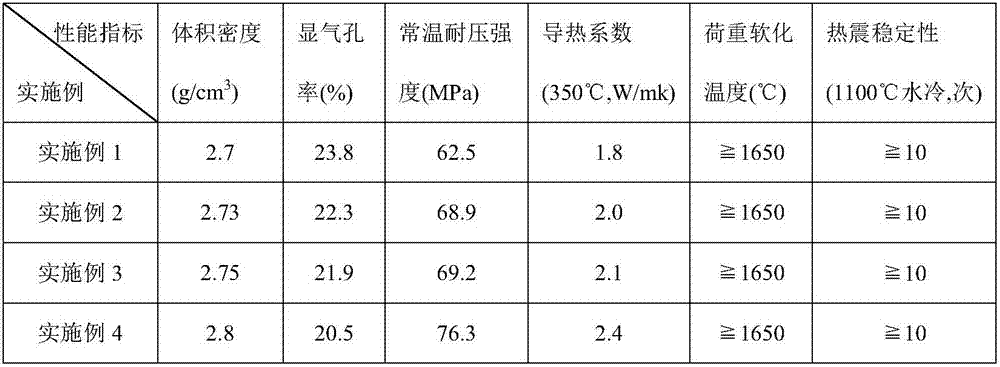

Examples

Embodiment 1

[0026] A low-conductivity magnesium-aluminum-zirconium composite brick. In terms of weight percentage, the low-conductivity magnesium-aluminum-zirconium composite brick consists of raw materials: 65% microporous magnesia, 25% high-purity magnesia, 5% fused magnesia-aluminum spinel, Zirconium dioxide 5%; plus pulp waste liquid accounting for 5% of the total weight of the above-mentioned raw materials; wherein, the microporous magnesia is made of microporous magnesia with a particle size of 3mm≤particle size2 o 3 The content is 60%; the bulk density of the fused magnesia-aluminum spinel is 3.2g / cm 3 ; The particle size of the zirconium dioxide 2 Content>90%; the specific gravity of the pulp waste liquid is 1.26g / cm 3 .

[0027] The microporous magnesia is formed by crushing and screening the microporous magnesia synthetic material, and the preparation method of the microporous magnesia synthetic material is as follows:

[0028] (1) Weigh 40wt% light-burned magnesium powder and...

Embodiment 2

[0032] A low-conductivity magnesium-aluminum-zirconium composite brick. In terms of weight percentage, the low-conductivity magnesium-aluminum-zirconium composite brick consists of raw materials: 30% of microporous magnesia, 50% of high-purity magnesia, 10% of fused magnesia-aluminum spinel, 10% of zirconium dioxide; plus 4% of the total weight of the above-mentioned raw materials pulp waste liquid; wherein, the microporous magnesia is made of microporous magnesia with a particle size of 3mm≤particle size2 o 3 The content is 50%; the bulk density of the fused magnesia-aluminum spinel is 3.25g / cm 3 ; The particle size of the zirconium dioxide 2 Content>90%; the specific gravity of the pulp waste liquid is 1.25g / cm 3 .

[0033] The microporous magnesia is formed by crushing and screening the microporous magnesia synthetic material, and the preparation method of the microporous magnesia synthetic material is as follows:

[0034](1) Weigh 10wt% light-burned magnesium powder and ...

Embodiment 3

[0038] A low-conductivity magnesia-aluminum-zirconium composite brick, characterized in that, in terms of weight percentage, the low-conductivity magnesia-aluminum-zirconium composite brick consists of 22% microporous magnesia, 60% high-purity magnesia, and fused magnesia-aluminum spinel 15% limestone, 3% zirconium dioxide; plus pulp waste liquid accounting for 4% of the total weight of the above raw materials; wherein, the microporous magnesia is made of microporous magnesia with 3mm≤particle size2 o 3 The content is 65%; the bulk density of the fused magnesia-aluminum spinel is 3.25g / cm 3 ; The particle size of the zirconium dioxide 2 Content>90%; the specific gravity of the pulp waste liquid is 1.25g / cm 3 .

[0039] The microporous magnesia is formed by crushing and screening the microporous magnesia synthetic material, and the preparation method of the microporous magnesia synthetic material is as follows:

[0040] (1) Weigh 90wt% light-burned magnesium powder and 10% ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com