Energy-saving and zero-emission multipurpose molecular-sieve dewatering device

A dehydration device and molecular sieve technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems that fuel gas cannot be effectively used, low-yield gas wells are shut down for a long time, and have not been developed and utilized. Convenience and creative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

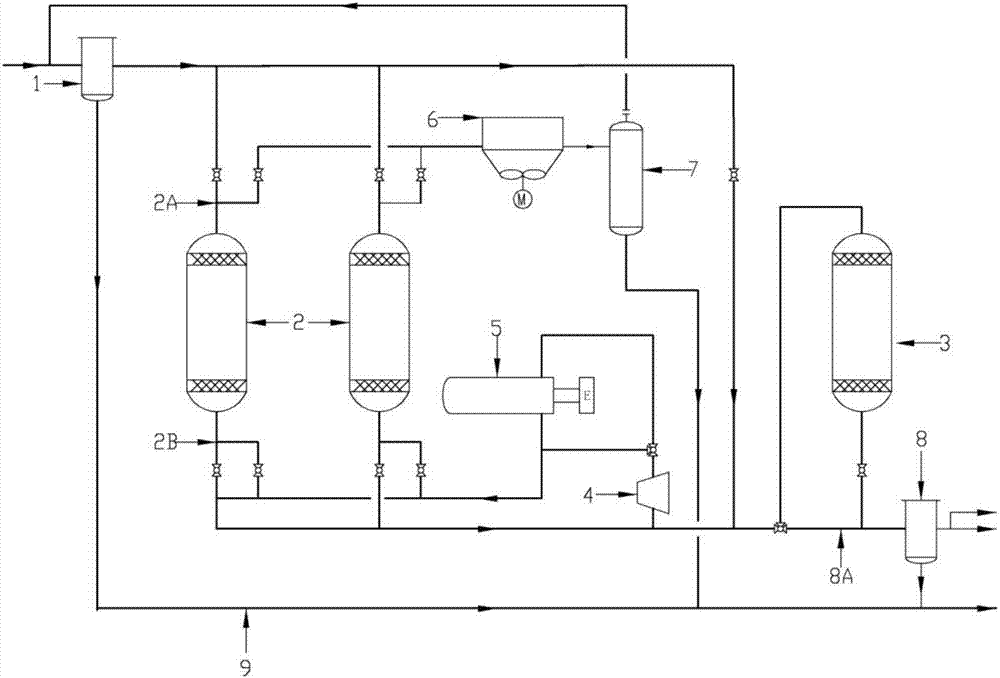

[0025] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0026] Such as figure 1 As shown, the output pipeline of the first filter separator 1 is divided into two paths, one of which is directly connected to the input pipeline 8A of the second filter separator 8. In order to prevent gas from flowing back, the first filter separator 1 is connected to the A valve is provided on the pipeline of the input pipeline 8A. The other way is connected to the first molecular sieve dehydration tower 2 through the first three-way pipe 2A, the other end of the first three-way pipe 2A is connected to the cooler 6, and the output end of the cooler 6 is connected to the separator 7 to separate The output end of the filter 7 is then connected to the input end of the first filter separator 1.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com