Coal mine working face rib fall monitoring system based on fiber grating and three dimensional laser scanning

A three-dimensional laser and fiber grating technology, which is applied in the measurement, measurement force, and measurement device of the change force of the optical properties of the material when it is stressed, can solve the problems of poor anti-electromagnetic interference, short service life, and external environmental influences. and other issues to achieve the effect of avoiding casualties, realizing underground disasters and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

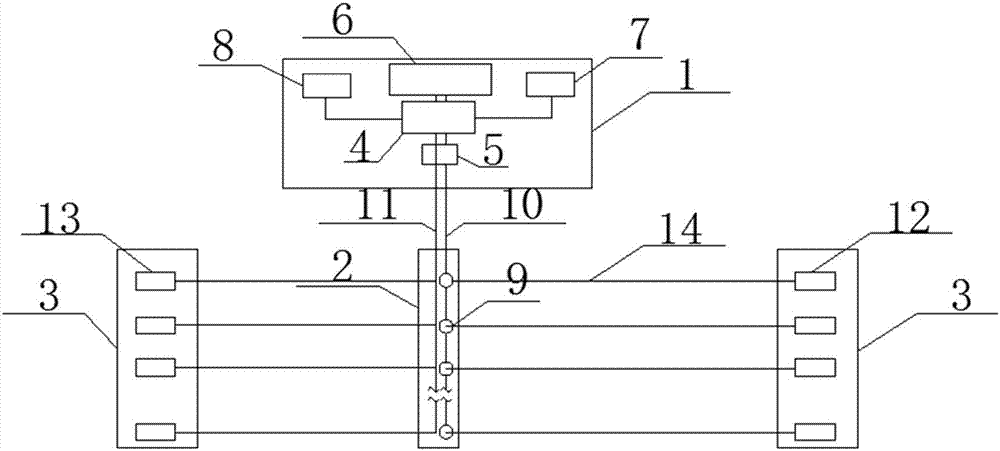

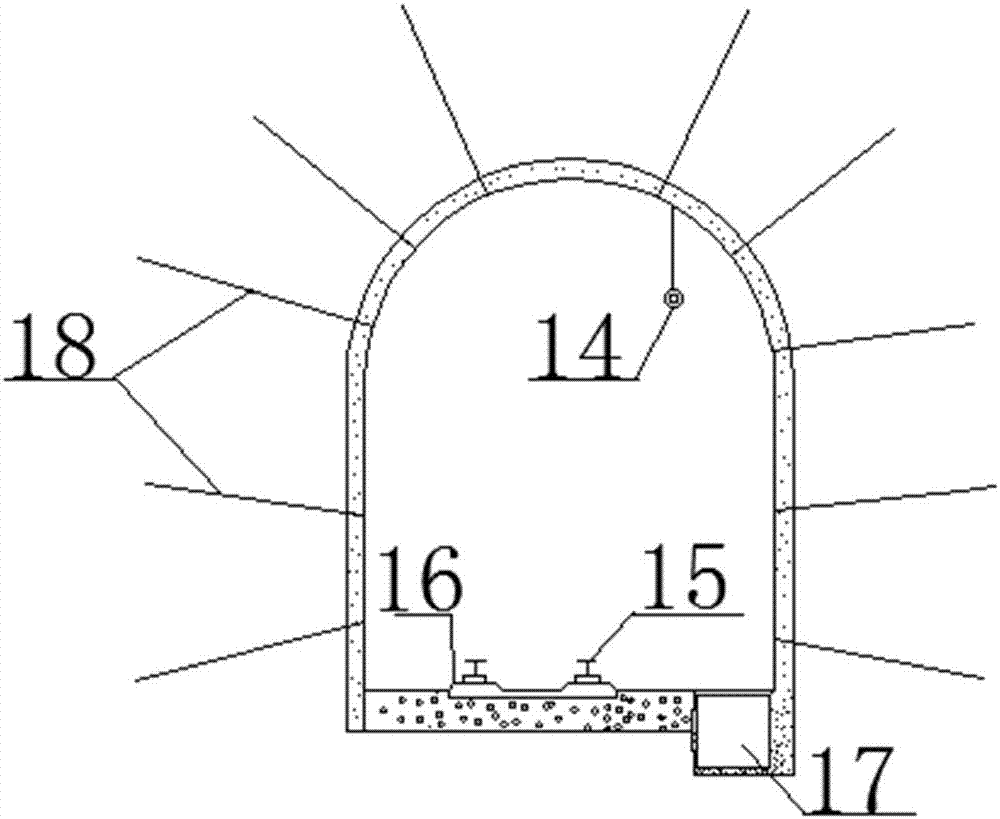

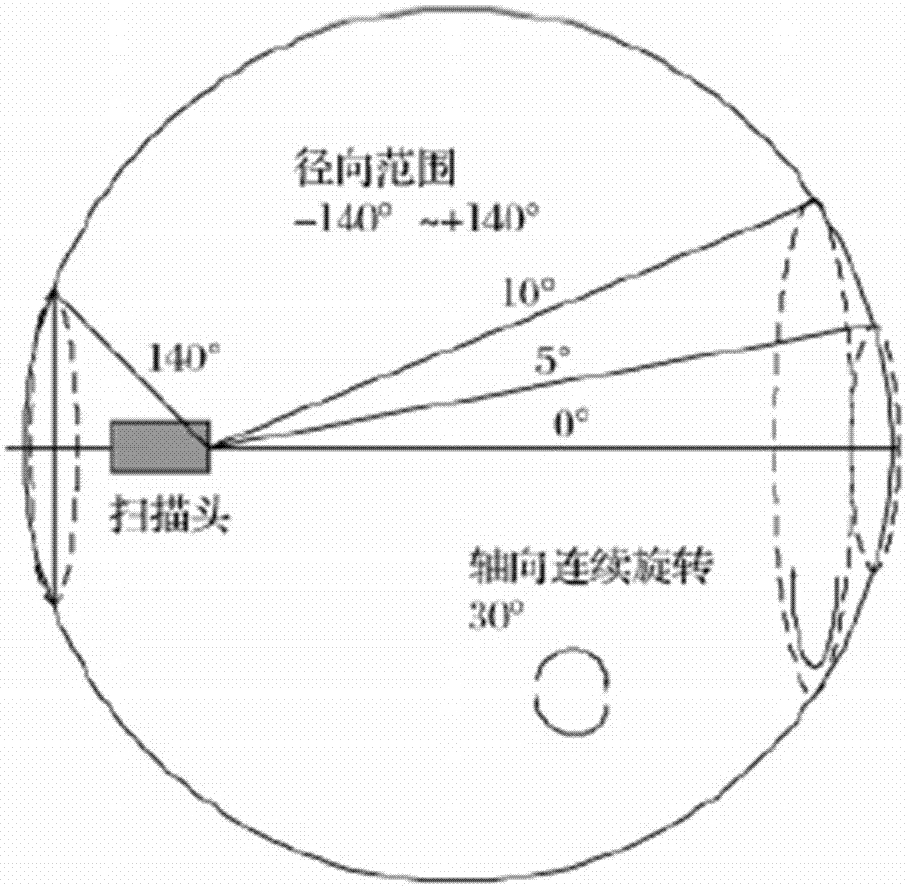

[0037] Embodiment 1: the monitoring system of coal mine working surface based on fiber grating and three-dimensional laser scanning, including ground data processing system (1), downhole data transmission system (2), downhole data acquisition system (3); described ground data The processing system (1) includes a main control computer and an optical fiber grating demodulator installed in the main control computer room on the ground, wherein the optical fiber grating demodulator (5) is connected with the main control computer (4) to realize the conversion of data signals and transmission, the main control computer (4) is installed with downhole data processing and modeling software, which can realize the processing of data such as the working resistance of the hydraulic support of the downhole working face, the sinking amount of the roof, and the temperature, and can simultaneously scan the point cloud data according to the three-dimensional laser Realize three-dimensional imagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com