Machining center tool decision making method for low-carbon manufacturing

A technology of machining centers and decision-making methods, used in manufacturing computing systems, genetic laws, predictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0164] The technical solutions of the present invention will be described below in conjunction with specific examples.

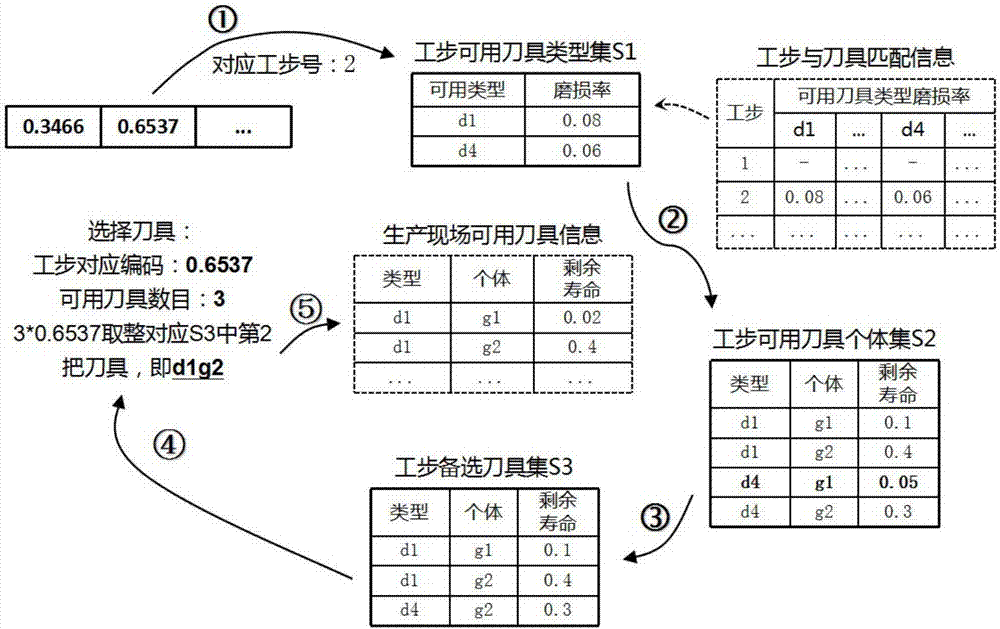

[0165] A batch of processing tasks containing 10 workpieces is assigned to a machining center for processing. Table 1 shows the specific information of this batch of workpieces. There are 6 types of tools used to process this batch of workpieces at the production site, and the available tool information is shown in Table 2.

[0166] Table 1 Processing task information table

[0167] Work No.

[0168] Table 2 Available Tool Information Table

[0169]

[0170] The following takes the working step 1 of the workpiece 1 as an example to illustrate the calculation process of the machining capacity of the available tool types in the working step. The machining allowance of work step 1 of workpiece 1 is:

[0171] Workpiece diameter D: 60mm; processing length L: 150mm; processing allowance Δ: 8mm.

[0172] It can be processed with tool type d1, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com