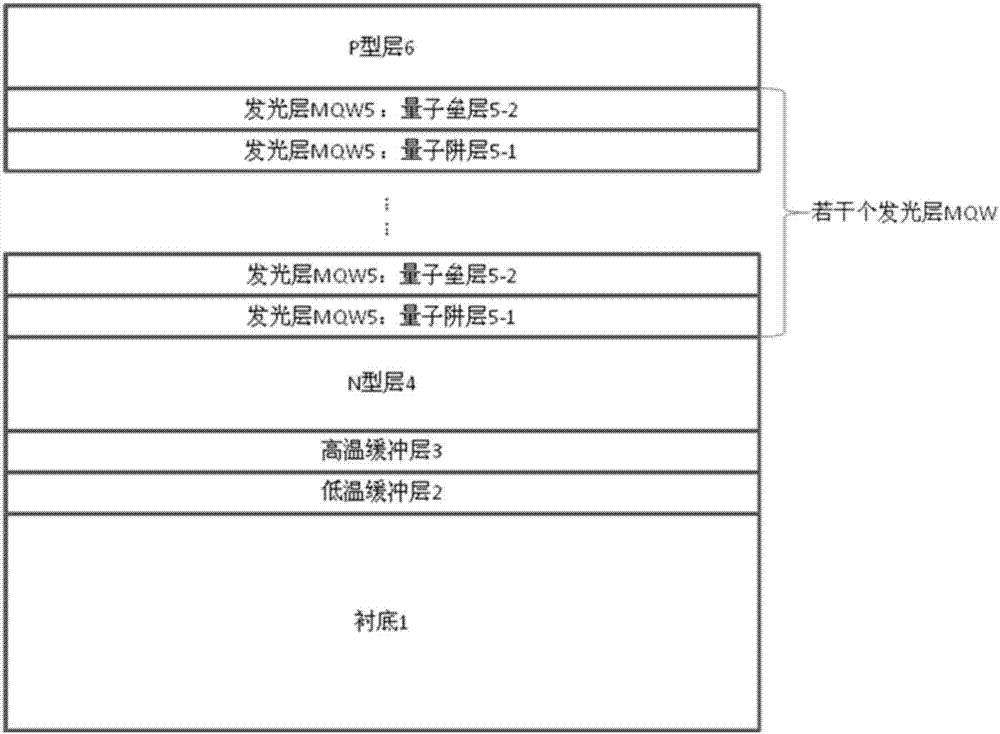

Epitaxial structure of light emitting diode

A technology of light-emitting diodes and epitaxial structures, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as the inability to effectively increase hole concentration, and achieve the effects of improving internal quantum efficiency, blocking electron overflow, and increasing concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0028] LED is a semiconductor solid-state light-emitting device, which mainly uses semiconductor P-N junction as a light-emitting structure. In recent years, semiconductor light-emitting diodes represented by gallium nitride have received extensive attention and vigorous research due to their excellent characteristics such as large band gap, high electron saturation electron drift velocity, high temperature resistance, and high power capacity. Breakthrough progress has been made in recent years. At the same time, as a ternary alloy of gallium nitride, indium gallium nitride, its bandgap is continuously adjustable from 0.7ev to 3.4ev, and its luminous wavelength covers the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com