Metal fiber atomizing core, atomizer and electronic cigarette

A metal fiber, atomizing core technology, used in tobacco, smoker's products, applications, etc., can solve problems such as failure to meet performance requirements, being burned, nickel-chromium alloy burning, etc., to improve high temperature resistance and fogging. Chemical efficiency, improve smoking experience, good high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

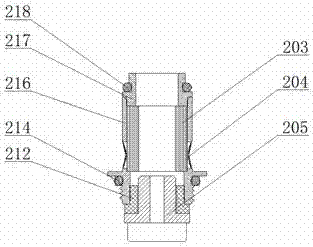

[0028] figure 1 The illustrated atomizing core sleeve 216 includes a tubular atomizing core sleeve 216 with an oil inlet 204 on the side wall, the conductive positive electrode 205 installed on one end of the atomizing core sleeve 216 through an insulating ring, and the atomizing core cover installed on the other end of the atomizing core sleeve 216 217; the atomizing core cover 217 is fitted with an atomizing core cover sealing ring 218 for connection and sealing, and the outer wall of the atomizing core cover 216 is set with an atomizing core cover sealing ring 214 for connecting and sealing; Inside the core cover 216, there is a metal fiber sheet 203 for absorbing e-liquid and capable of conducting heat.

[0029] During assembly, the two lead angles of the metal fiber sheet 203 are in contact with the atomizing core 216 and the conductive positive electrode 205 respectively, and the negative electrode is connected to the atomizing core 216; obviously other connection method...

Embodiment 2

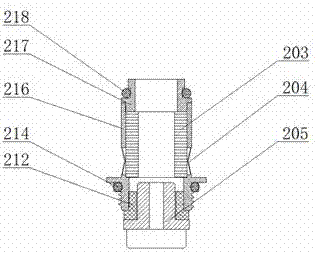

[0031] figure 2 The structure of the metal fiber atomizing core shown is basically the same as that of the first embodiment. The difference is that the shape, fiber size, material and properties of the metal fiber sheet are all different from the first embodiment. Specifically, the metal fiber sheet in this example is made of stainless steel long fibers with a diameter of 500 μm prepared by the melting method and twisted. It has a porosity of 10% and a specific surface area of 0.1 m 2 / g, making the resistance 0.5Ω at the fixed size determined.

Embodiment 3

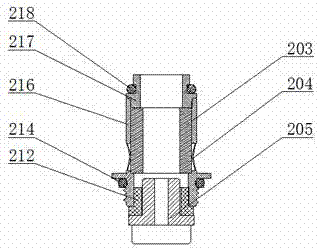

[0033] image 3 The structure of the metal fiber atomizing core shown is basically the same as that of the first embodiment. The difference is that the shape, fiber size, material and properties of the metal fiber sheet are all different from the first embodiment. Specifically, the metal fiber sheet in this example is made of short copper fibers with a diameter of 50 μm prepared by the cluster wire drawing method and is sintered at a high temperature. It has a porosity of 83% and a specific surface area of 10 m 2 / g, making the resistance 0.1Ω at the fixed size determined.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com