Graphene-plant composite type flame-retardant fire extinguishing agent

A graphene and composite technology, applied in fire protection equipment and other directions, can solve the problems such as the research and report on graphene plant-based composite flame retardant fire extinguishing agent, the limited improvement of fire extinguishing performance, and the unsatisfactory test results. It is beneficial to the restoration of the fire scene ecology, the production process is simple and easy to implement, and the effect of excellent flame retardant and fire-extinguishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

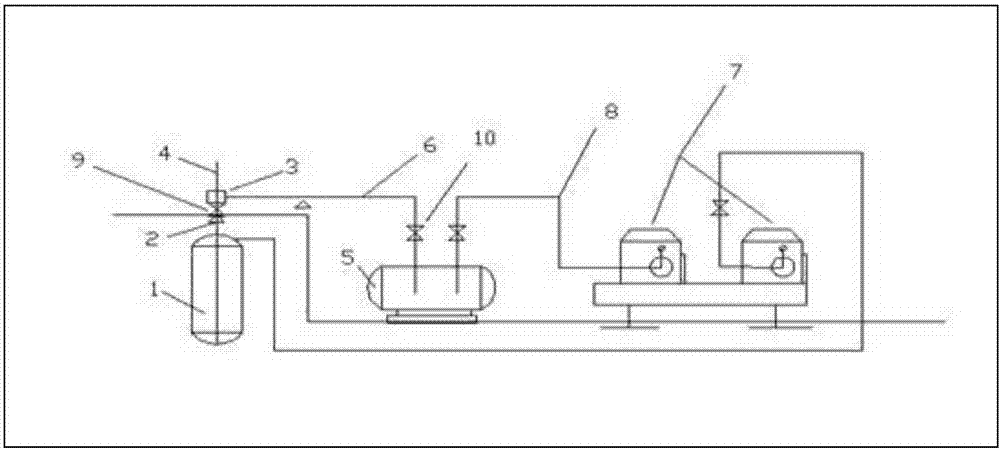

Image

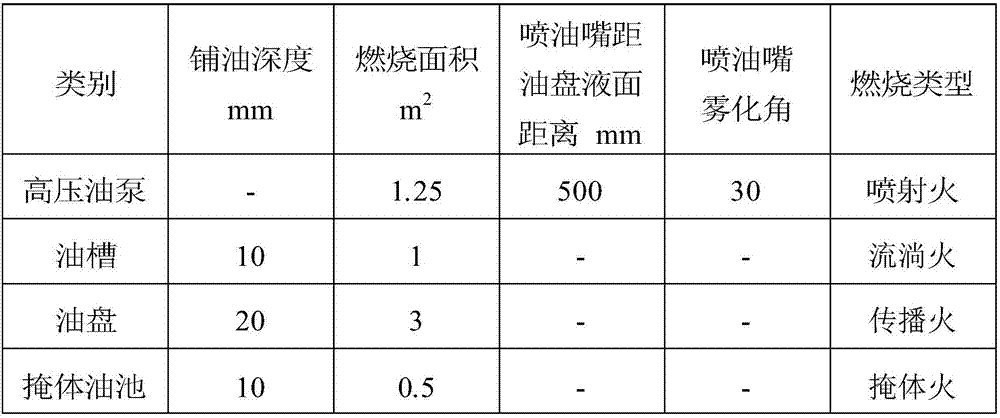

Examples

Embodiment 1

[0046] A kind of graphene plant composite flame retardant fire extinguishing agent is made of the raw materials of following parts by weight:

[0047] Plant extract 26, plant ash 10, graphene 3.5, aluminum hydroxide 6, and the balance is water.

[0048] The preparation method is as follows:

[0049] (1) Take the plant material of following parts by weight:

[0050] Corn silk 20, rags 8, yam 15, elm bark 10, grapefruit peel 10;

[0051] Mix corn silk, rags, yam, elm bark and pomelo peel, add 12 times the amount of water after drying and crushing, soak for 2 hours, cook for 2 hours, filter, and use the filtrate for later use, then add 10 times the amount of water to the filter residue, Ultrasonic extraction for 1 hour, filtering, and combining the filtrates to obtain the plant extract;

[0052] (2) Add 15 times the amount of water to the dried plant ash, soak for 1 hour, decoct for 1 hour, filter, and the filtrate is for subsequent use. Under the same conditions, the filter r...

Embodiment 2

[0055] A kind of graphene plant composite flame retardant fire extinguishing agent is made of the raw materials of following parts by weight:

[0056] Plant extract 30, plant ash 12, graphene 4.5, aluminum hydroxide 4, magnesium hydroxide 4, and the balance is water.

[0057] The preparation method is as follows:

[0058] (1) Take the plant material of following parts by weight:

[0059] Corn silk 30, rags 10, yam 20, elm bark 15, grapefruit peel 15;

[0060] Mix corn silk, rags, yam, elm bark and pomelo peel, add 10 times the amount of water after drying and crushing, soak for 2 hours, cook for 2 hours, filter, and use the filtrate for later use, then add 10 times the amount of water to the filter residue, Ultrasonic extraction for 1 hour, filtering, and combining the filtrates to obtain the plant extract;

[0061] (2) Add 15 times the amount of water to the dried plant ash, soak for 1 hour, decoct for 1 hour, filter, and the filtrate is for subsequent use. Under the same ...

Embodiment 3

[0064] A kind of graphene plant composite flame retardant fire extinguishing agent is made of the raw materials of following parts by weight:

[0065] Plant extract 26, plant ash 10, graphene 3.5, aluminum hydroxide 6, coconut shell powder 3.0, and the balance is water.

[0066] The preparation method is as follows:

[0067] (1) Take the plant material of following parts by weight:

[0068] Corn silk 20, rags 8, yam 15, elm bark 10, grapefruit peel 10;

[0069] Mix corn silk, rags, yam, elm bark and pomelo peel, add 12 times the amount of water after drying and crushing, soak for 2 hours, cook for 2 hours, filter, and use the filtrate for later use, then add 10 times the amount of water to the filter residue, Ultrasonic extraction for 1 hour, filtering, and combining the filtrates to obtain the plant extract;

[0070] (2) Add 15 times the amount of water to the dried plant ash, soak for 1 hour, decoct for 1 hour, filter, and the filtrate is for subsequent use. Under the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com