Method for quickly synthesizing tin selenide nano sheet by microwave assistance

A microwave-assisted, tin selenide technology, applied in nanotechnology, binary selenium/tellurium compounds, etc., can solve the problems of long synthesis time, expensive materials, complex synthesis process, etc., and achieve efficient use of energy, saving preparation time, size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

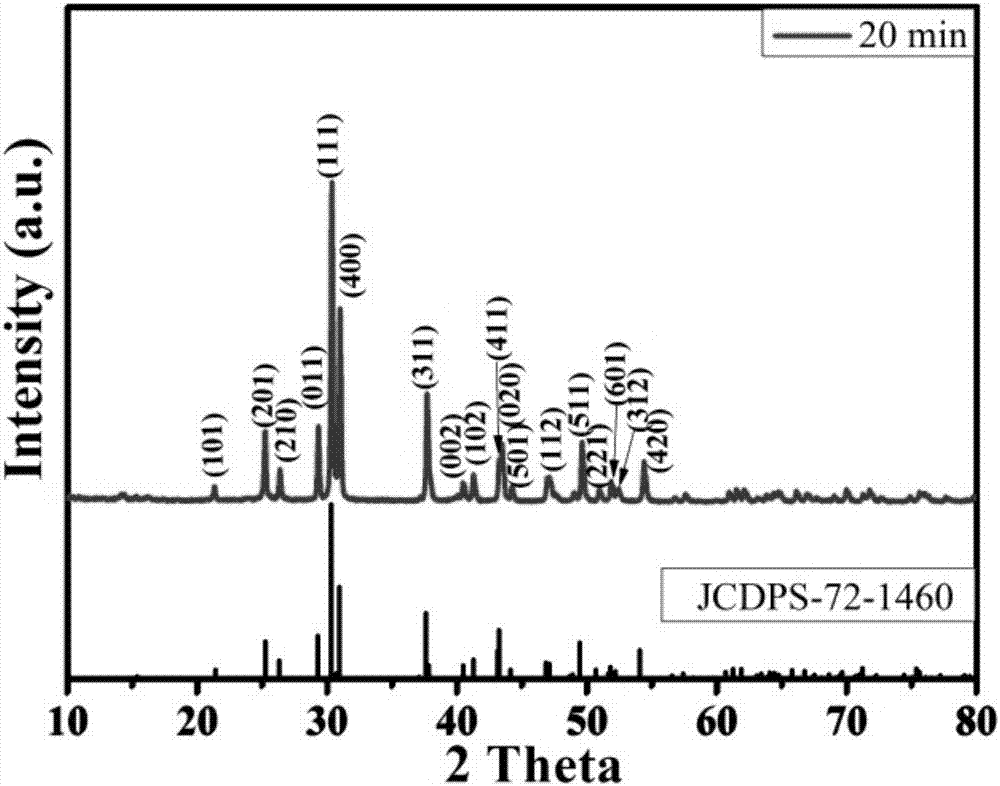

Embodiment 1

[0030] The preparation of SnSe includes the following steps:

[0031] Step 1, 0.902g stannous chloride dihydrate (SnCl 2 2H 2 (2), 0.16g selenium powder (Se), 8g potassium hydroxide (KOH) and 120ml ethylene glycol join in the beaker, 100 ℃ of oil bath heating and stirring 40min;

[0032] Step 2, add 4g potassium borohydride (KBH 4 ) Continue heating in an oil bath and stir until no bubbles are produced, then cool to room temperature;

[0033] Step 3. Transfer to a household microwave oven (Galanz, P70F23P-G5(SO)) and heat at medium-low heat for 8 minutes, rest for 2 minutes, and black precipitate appears after reheating for 7 minutes, and cool down to room temperature again;

[0034] Step 4, extracting the black product obtained by centrifuging at a speed of 4000r / min for 5min;

[0035] Step 5, alternately add ethylene glycol and ethanol to the black product and centrifuge at a speed of 10000r / min for 5min to remove impurities;

[0036] Step 6. Finally, place the cleaned ...

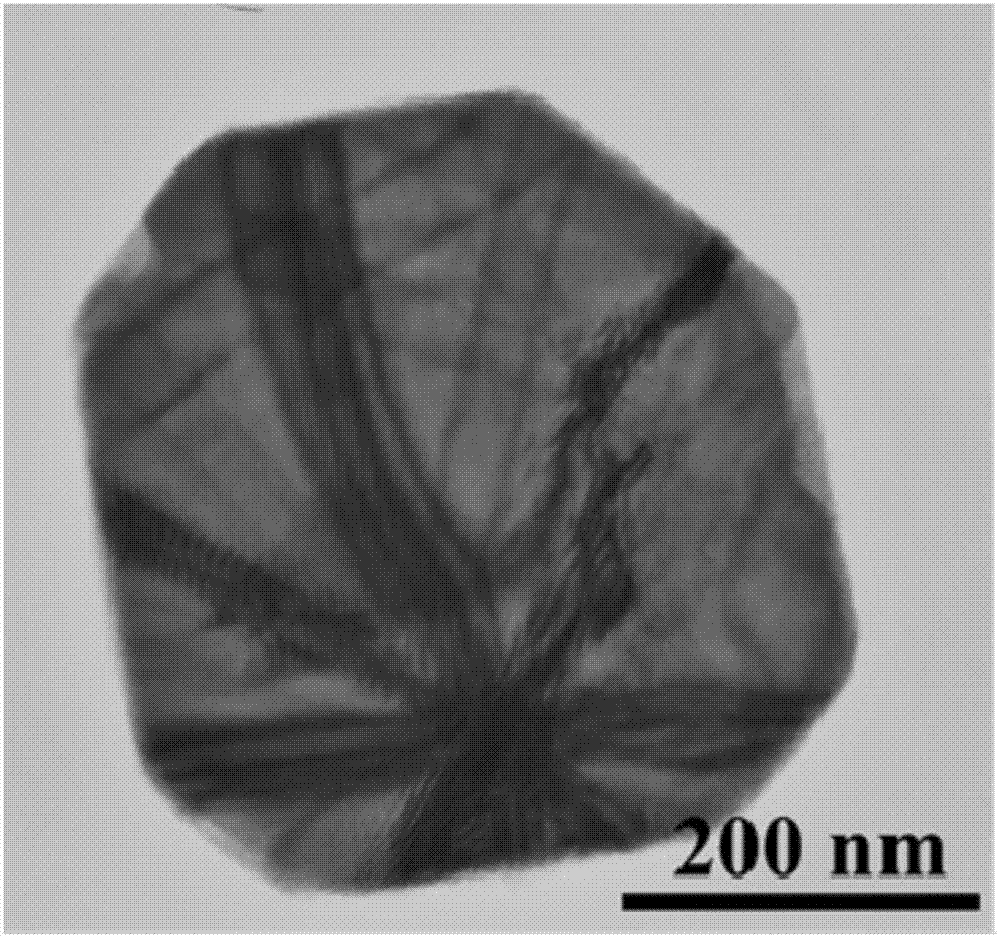

Embodiment 2

[0039] The preparation of SnSe includes the following steps:

[0040] Step 1, 0.45g stannous chloride dihydrate (SnCl 2 2H 2 (2), 0.16g selenium powder (Se), 4g potassium hydroxide (KOH) and 120ml ethylene glycol join in the beaker, 100 ℃ of oil bath heating and stirring 30min;

[0041] Step 2, add 2g potassium borohydride (KBH 4 ) Continue heating in an oil bath and stir until no bubbles are produced, then cool to room temperature;

[0042] Step 3. Transfer to a household microwave oven (Galanz, P70F23P-G5(SO)) and heat at medium-low heat for 8 minutes, rest for 2 minutes, and black precipitate appears after reheating for 15 minutes, and then cool to room temperature again;

[0043] Step 4, extracting the black product obtained by centrifuging at a speed of 4000r / min for 5min;

[0044] Step 5. Alternately add ethylene glycol and ethanol to the black product and centrifuge at a speed of 8000r / min for 5min to remove impurities;

[0045] Step 6. Finally, place the cleaned b...

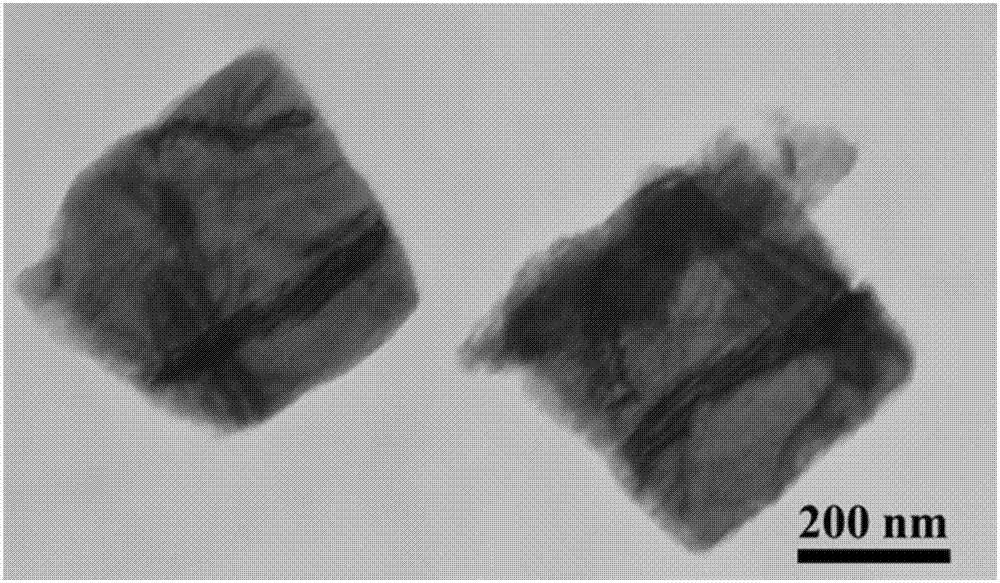

Embodiment 3

[0048] The preparation of SnSe includes the following steps:

[0049] Step 1, 0.451g stannous chloride dihydrate (SnCl 2 2H 2 (2), 0.16g selenium powder (Se), 4g potassium hydroxide (KOH) and 120ml ethylene glycol join in the beaker, 100 ℃ of oil bath heating and stirring 30min;

[0050] Step 2, add 2g potassium borohydride (KBH 4 ) Continue heating in an oil bath and stir until no bubbles are produced, then cool to room temperature;

[0051] Step 3. Transfer to a household microwave oven (Galanz, P70F23P-G5(SO)) and heat at medium-low heat for 10 minutes, rest for 3 minutes, and reheat for 10 minutes. After 20 minutes of heating, a black precipitate appears, and cool to room temperature again;

[0052] Step 4, extracting the black product obtained by centrifuging at a speed of 4000r / min for 5min;

[0053] Step 5, alternately add ethylene glycol and ethanol to the black product and centrifuge at a speed of 10000r / min for 5min to remove impurities;

[0054]Step 6. Finally,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com