Two-stage membrane aerated bioreactor for deep sewage treatment

A technology of aerated organisms and membrane reactors, applied in biological water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve insufficient ammonia oxidation activity, denitrification denitrification limitation, and ammonia nitrogen cannot be obtained Further oxidation and other problems, to achieve the effect of stable physiological function activity, low sludge output, and efficient sewage treatment benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

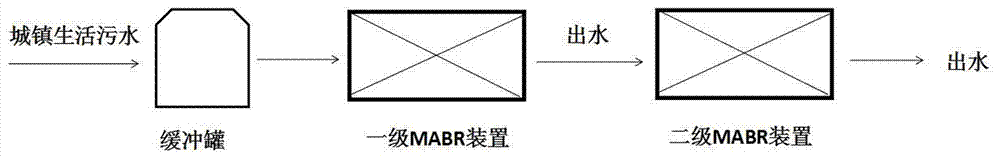

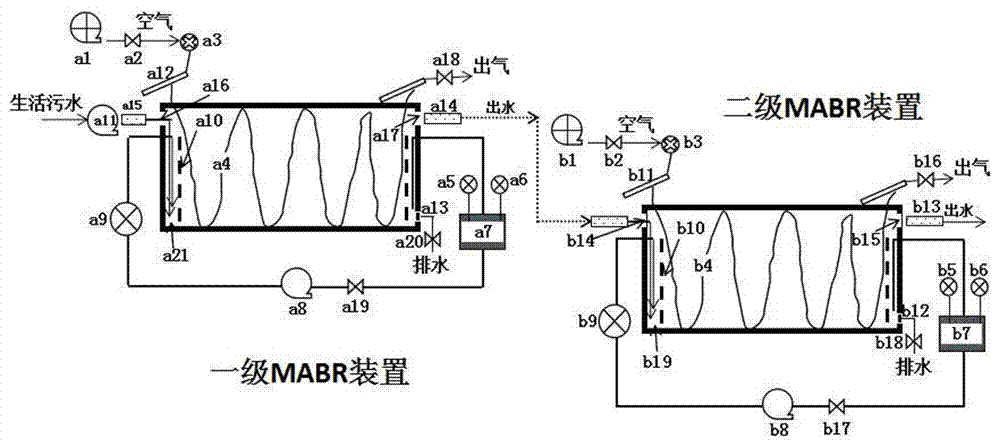

[0072] 1) Structural composition and related parameters of the sewage treatment system: indicated by a two-stage MABR reactor figure 1 It can be seen that the system is composed of primary MABR and secondary MABR biochemical units. The structure of the two-level unit is according to the figure 2 The flow chart shown is created. PVDF hollow fiber dense membrane modules are used, with an outer diameter of 4.1 mm, an inner diameter of 2.2 mm, and a pore size of 0.05-0.06 μm; the volume of the membrane pool is different, the first level is 5 L, and the second level is 2 L; the effective membrane specific surface area is different, the first level is 450m 2 / m 3 , Level 2 200 m 2 / m 3 ; The formation process of biofilm is different: the biofilm of the first-level MABR device is formed by natural hanging film; the biofilm of the second-level MABR device is formed by artificial hanging film (see Section 2) and Section 3) for details).

[0073] 2) Process conditions: The sewage...

Embodiment 2

[0078] 1) Structural composition and related parameters of the sewage treatment system: indicated by a two-stage MABR reactor figure 1 It can be seen that the system is composed of primary MABR and secondary MABR biochemical units. The structure of the two-level unit is according to the figure 2 The flow chart shown is created. The PP hollow fiber dense membrane module is used, with an outer diameter of 3.7 mm, an inner diameter of 2.3 mm, and a pore size of 0.07-0.08 μm; the volume of the membrane pool is different, the first level is 6 L, and the second level is 2.5 L; the effective membrane specific surface area is different, the first level is 550m 2 / m 3 , Level 2 265 m 2 / m 3 ; The formation process of biofilm is different: the biofilm of the first-level MABR device is formed by natural hanging film; the biofilm of the second-level MABR device is formed by artificial hanging film (see Section 2) and Section 3) for details).

[0079] 2) Process conditions: Sewage c...

Embodiment 3

[0084] 1) Structural composition and related parameters of the sewage treatment system: indicated by a two-stage MABR reactor figure 1 It can be seen that the system is composed of primary MABR and secondary MABR biochemical units. The structure of the two-level unit is according to the figure 2 The flow chart shown is created. PTFE hollow fiber dense membrane modules are used, with an outer diameter of 3.8 mm, an inner diameter of 2.5 mm, and a pore diameter of 0.06 μm; the volume of the membrane pool is different, the first stage is 7 L, and the second stage is 3 L; the effective membrane specific surface area is different, the first stage is 600 m 2 / m 3 , Level 2 300 m 2 / m 3 ; The formation process of biofilm is different: the biofilm of the first-level MABR device is formed by natural hanging film; the biofilm of the second-level MABR device is formed by artificial hanging film (see Section 2) and Section 3) for details).

[0085] 2) Process conditions: Sewage come...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com