Filtering and purifying system for drip irrigation equipment

A technology for filtering impurities and equipment, which is applied in the field of water purification devices for drip irrigation equipment. It can solve problems such as easy blockage of drippers, low working efficiency of cyclone dust collectors, and differences in working principles, so as to reduce the possibility of soil salinization and improve equipment. Impurity removal efficiency, low water quality softening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

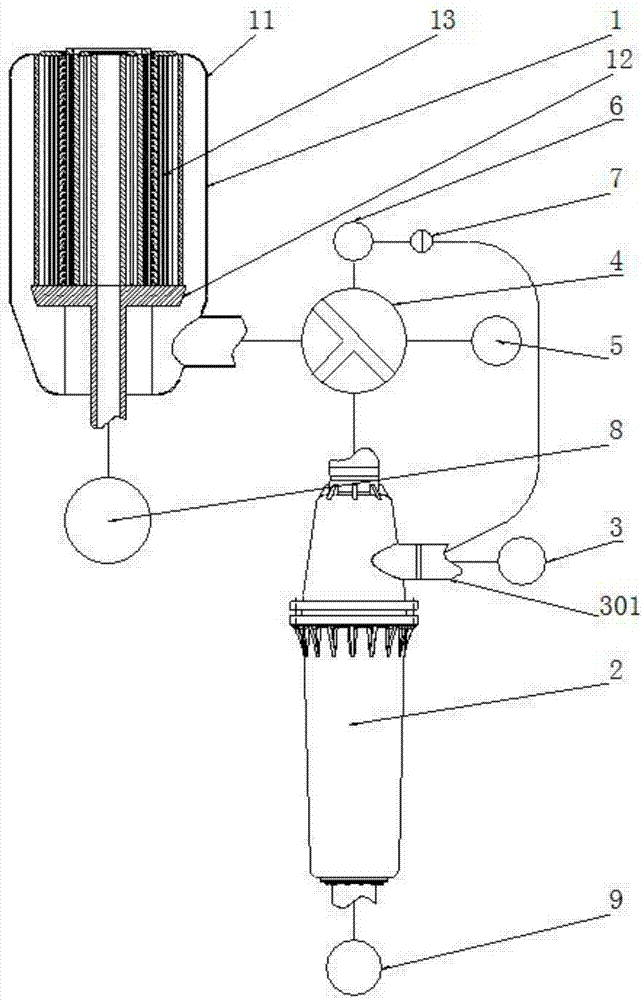

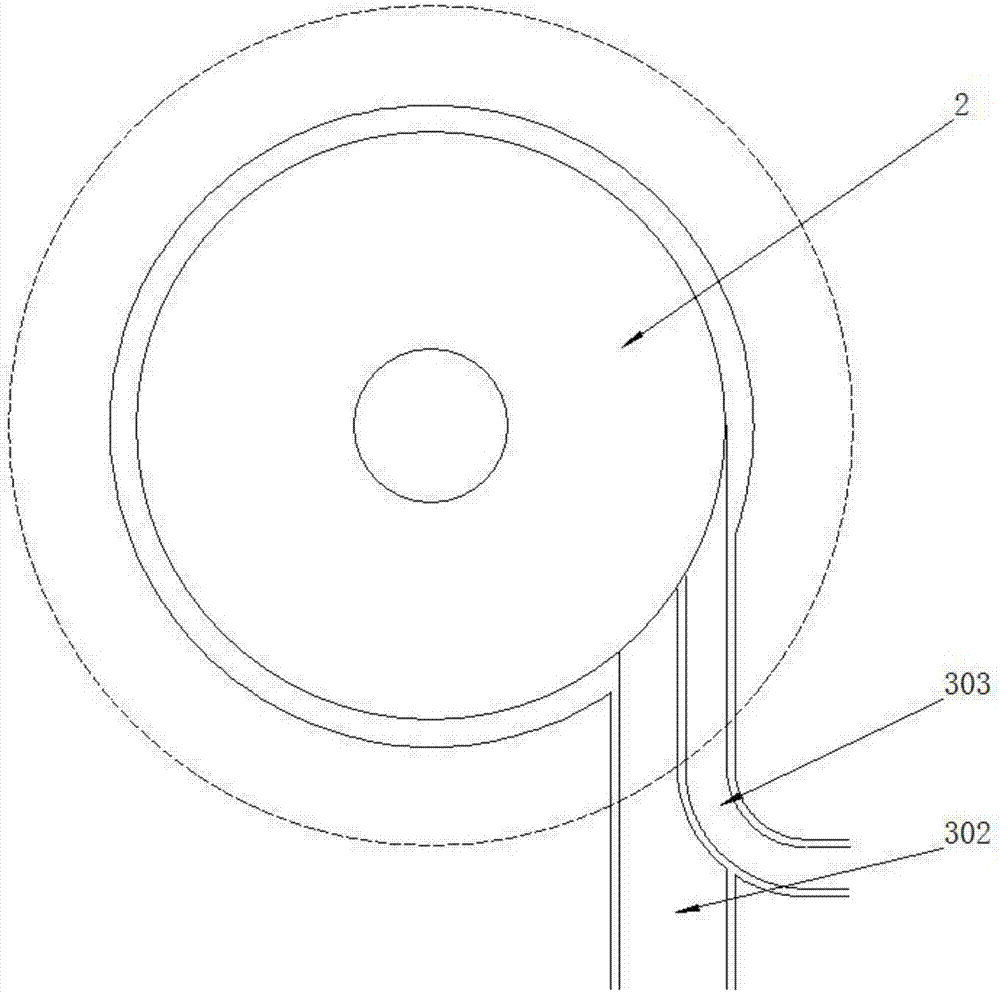

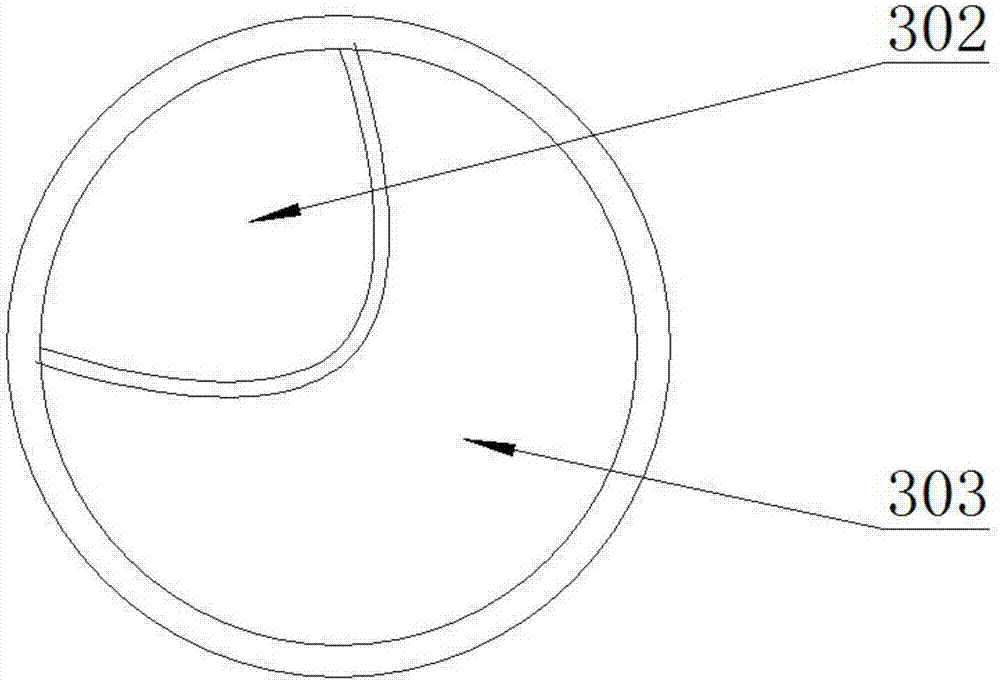

[0020] The filter and impurity removal system for drip irrigation equipment is characterized in that: it includes an anti-scale laminated filter 1, a cyclone dust collector 2, a main water inlet pipe 3, a casing water inlet 301, a four-way valve 4, a sewage pipe 5, Circulation pump 6, circulation pump valve 7, main water outlet pipe 8 and sand discharge pipe 9; among them, casing water inlet 301 is installed at the entrance of cyclone dust collector 2, and its outer pipe 302 is connected to main water inlet pipe 3 and four-way valve 4 Each end is respectively connected to the water outlet of the cyclone dust collector 2, the water inlet pipe 1101 of the anti-scaling laminated filter, the circulation pump 6 and the sewage pipe 5; the water outlet of the circulation pump 6 is connected to the inner pipe of the sleeve type water inlet through the circulation pump valve 7 303; the outlet pipe 1201 of the anti-scaling laminated filter is connected to the main outlet pipe 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com