Environment-friendly glass wool comprising nanoparticle layer

A nanoparticle and glass wool technology, applied in the field of thermal insulation materials, can solve the problems of high consumption, lack of suitable materials for thermal insulation, and inability to meet the requirements, achieving the convenience of enterprise production and building construction, improving thermal insulation and thermal insulation effects, and reducing thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

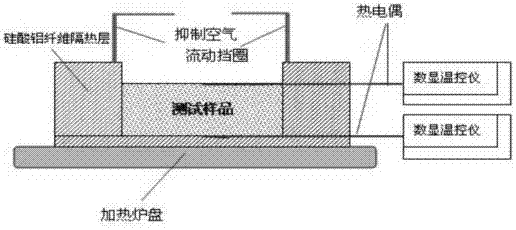

Method used

Image

Examples

Embodiment 1

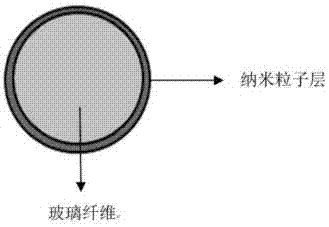

[0059] Nano-SiO2 has the following basic properties: specific surface area is 200±25m2 / g; loss on drying is 1% (drying at 100°C for 2h); loss on ignition is 4% (burning at 1000°C for 2h); purity is 99.8% The pH value of the suspension is 3.7-4.7 (4% aqueous suspension); the bulk density is 50g / L; the particle size range is 10nm-18nm; the average particle size is about 15nm.

[0060] Nano-SiO2 was added to 73 g of the above-mentioned glass fibers, and stirred at a speed of 100 r / min for 1 hour, so that the nanoparticles were evenly attached to the surface of the glass fibers, and a composite of nanoparticles and glass fibers was obtained.

[0061] Spray 8g of acrylic resin binder (provided by the factory for direct spraying) into the composite of the above-mentioned nanoparticles and glass fibers, and then put it into a mold and use a YES-300 pressure testing machine for compression molding. During the pressing process, the pressure was first applied slowly by controlling the a...

Embodiment 2

[0064] In addition to adding half a quantity of nano-SiO2 and silicon carbide equivalent to nano-SiO2 (the particle size range is 2 μm to 4 μm; the average particle size is about 3 μm), the same method as in Example 1 is used to prepare the nano-particle layer of the present invention. Environmentally friendly glass wool. The thickness of the nanoparticle layer is 1 / 33 of the diameter of the glass fiber.

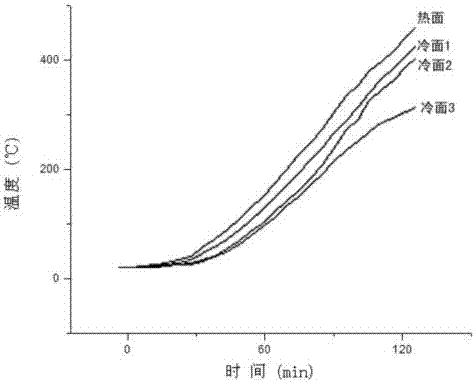

[0065] The results of the back temperature test were as follows: image 3 shown. It can be seen that the maximum temperature difference between the hot surface and the cold surface 3 of the glass wool is 121 degrees, and the gap tends to widen.

Embodiment 3

[0067] In addition to adding half the amount of nano-SiO2, silicon carbide equivalent to nano-SiO2 (the particle size range is 2 μm to 4 μm; the average particle size is about 3 μm), and nano-Al2O3 (average particle size is about 30nm~ About 50nm), adopt the same method as Example 1 to prepare the environment-friendly glass wool with nano particle layer of the present invention. The thickness of the nanoparticle layer is 1 / 33 of the diameter of the glass fiber.

[0068] The results of the back temperature test show that the thermal insulation effect of the glass wool is better than that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com