Early strength type high-strength non-shrinkage grouting material with large mixing amount of mineral slag

A heavy slag, early-strength technology, applied in the field of high-volume heavy slag early-strength high-strength non-shrinkage grouting materials, can solve the problems of inability to meet fast-hardening and early-strength, consumption of quartz sand resources, and large fluidity loss, etc. The effect of stable strength, ensuring continuous development, and promoting early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

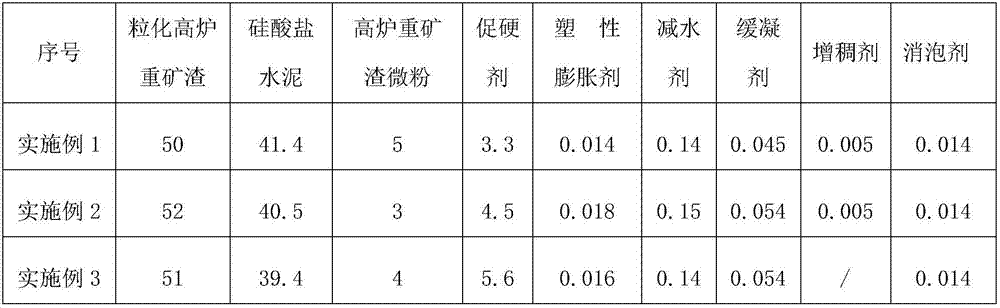

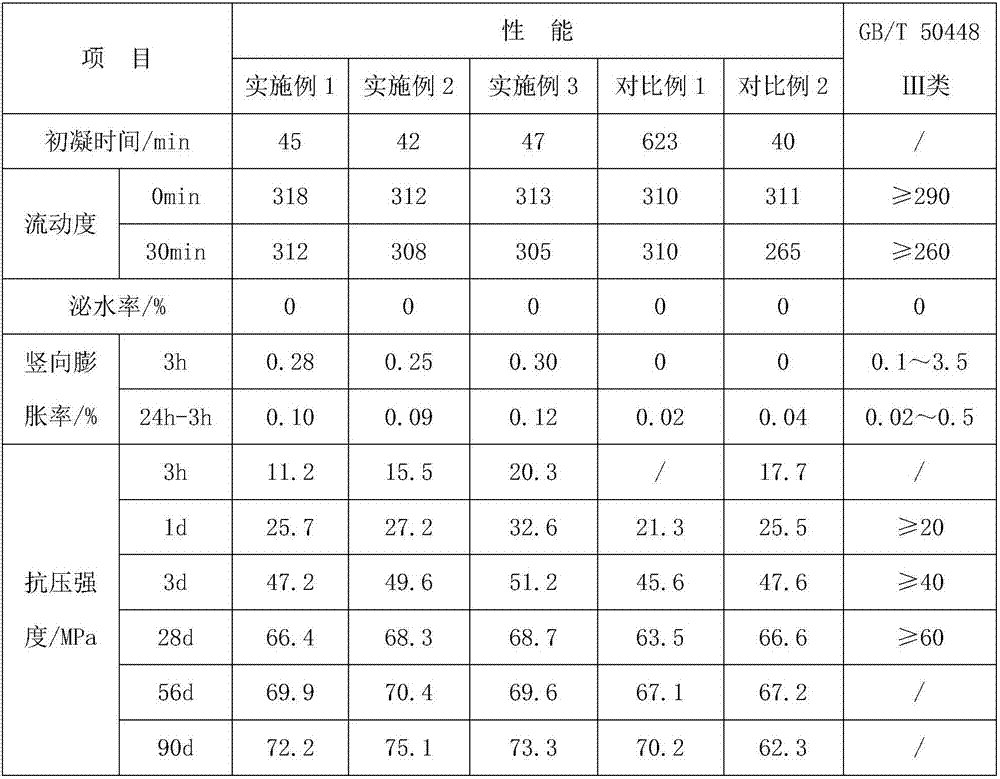

[0026] The ratio of raw materials is as shown in Table 1:

Embodiment 1

[0027] The distribution ratio of each component of the large-volume heavy slag early-strength high-strength non-shrinkage grouting material described in Example 1 is calculated in parts by weight: 50 parts of granulated blast furnace heavy slag, 5 parts of blast furnace heavy slag fine powder, ordinary portland cement 41.4 parts, 3.3 parts of amorphous calcium aluminate, 0.014 parts of azodicarbonamide, 0.14 parts of polycarboxylate superplasticizer, 0.045 parts of boric acid, 0.005 parts of hydroxypropyl methylcellulose ether, 0.014 parts of silicone defoamer share.

Embodiment 2

[0028] The distribution ratio of each component of the large-volume heavy slag early-strength high-strength non-shrinkage grouting material described in Example 2 is calculated in parts by weight: 52 parts of granulated blast furnace heavy slag, 3 parts of blast furnace heavy slag fine powder, ordinary Portland cement 40.5 parts, 4.5 parts of amorphous calcium aluminate, 0.018 parts of azodicarbonamide, 0.15 parts of polycarboxylate superplasticizer, 0.054 parts of boric acid, 0.005 parts of hydroxyethyl methyl cellulose ether, 0.014 parts of polyether defoamer share.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com