Ultrahigh-temperature composting method for treating vegetable waste

A vegetable waste and treatment method technology, applied in the field of ultra-high temperature composting of vegetable waste, can solve the problems of easy safety risks in utilization and difficult recycling of vegetable waste, so as to improve the degree of harmlessness, reduce investment, The effect of improving the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, the ultra-high temperature composting treatment method of cucumber seedlings

[0039] Mix cucumber seedlings, corn stalks, wheat straw and chicken manure according to the dry weight ratio of 1:0.45:0.55:0.3, and add the uniformly mixed materials (with a particle size of 2-5cm) into the composting reactor. The carbon-to-nitrogen ratio is about 25, and the moisture content is about 60%. Under the room temperature of 15-20°C, forced ventilation is carried out for 40 days (the ventilation rate is 0.2L·min -1 ·kgDM -1 ) under the composting process, the composting operation was carried out on the 3rd, 7th, 12th, 17th, 22nd, 27th, 32nd, 37th day and the moisture content was adjusted to about 60% at the same time.

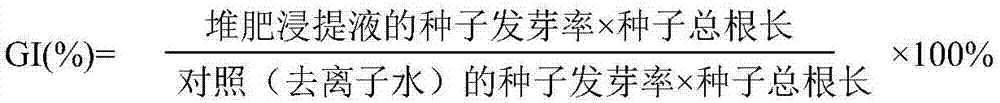

[0040] On the first day of the composting reaction, the temperature rose rapidly to above 70°C, and the high temperature above 70°C lasted for 1.4 days. Since the 12th day, the germination rate index (GI value) has been higher than 80%, reaching the...

Embodiment 2

[0045] Embodiment 2, the processing method of the cucumber seedling ultra-high temperature composting that adds microbial bacterial agent

[0046] After mixing tomato seedlings, corn stalks, wheat straw and chicken manure according to the dry weight ratio of 1:0.43:0.57:0.3, add them to the mixed material (the particle size of the mixed material is 3-5cm) according to the weight ratio of 3‰ The compost inoculant (VT1000 bacterial agent) is added by dissolving it with molasses and spraying it evenly on the surface of the mixture. The obtained mixture is 0.35kg·L according to the wet bulk density -1 Add in the composting reactor, the carbon-nitrogen ratio of mixture is about 25, moisture content is about 60%, carry out a period of 40 days of forced ventilation under the room temperature condition of 15-20 ℃ (ventilation rate is 0.25L min -1 ·kgDM -1 ) under the composting process, the composting operation was carried out on the 3rd, 7th, 12th, 17th, 22nd, 27th, 32nd, 37th day ...

Embodiment 3

[0048] Embodiment 3, using chemical additives to control the method of ultra-high temperature composting of cucumber seedlings for nitrogen loss

[0049] After mixing chili seedlings, corn stalks, wheat stalks and chicken manure according to the dry weight ratio of 1:0.40:0.60:0.3, the content of easily biodegradable organic matter in the mixture is 45%. Add the compost inoculant (VT1000 bacterial agent) to the mixed material (the mixed material particle size is 2-5cm) according to the weight ratio of 3‰, and the addition method is to dissolve it with molasses and evenly spray it on the surface of the mixture. Add 5% magnesium phosphate salt additive (K 2 HPO 4 and MgO according to the molar ratio of 1:2 mixed into the mixed material), the resulting mixture according to the wet bulk density of 0.35kg L -1 Add in the composting reactor, the carbon-nitrogen ratio of mixture is about 25, moisture content is about 60%, carry out a period of 40 days of forced ventilation (ventila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com