A kind of controllable slow-release fertilizer and preparation method thereof

A slow-release fertilizer and soluble technology, applied in the field of controlled-release fertilizer, can solve the problems of fertilizer efficiency waste, plant damage, etc., and achieve the effect of good water retention and prolonging the fertilizer release cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

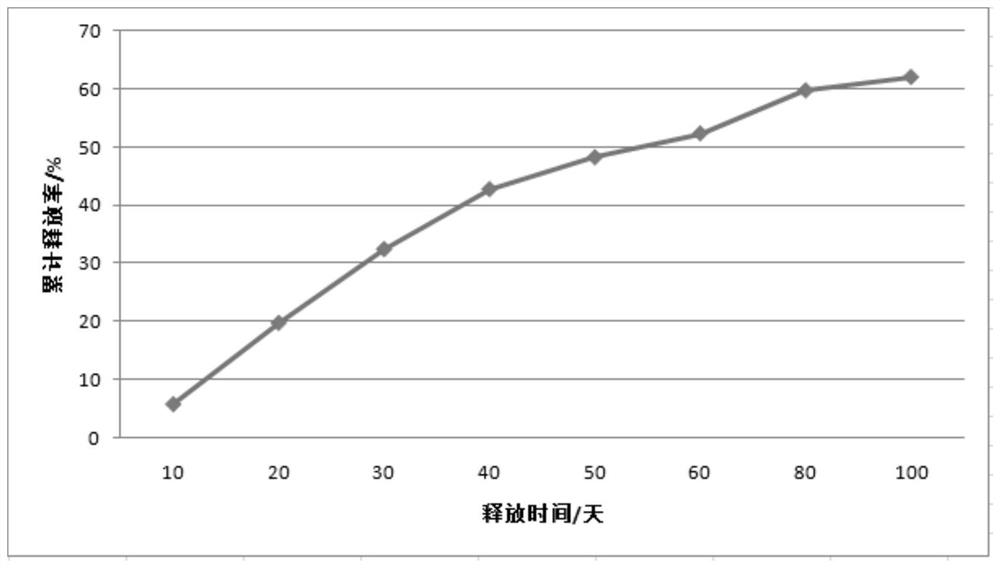

Embodiment 1

[0022] A controllable slow-release fertilizer, the preparation method of which comprises the following steps:

[0023] (1) Wrap a layer of soluble starch film on the surface of sodium hydroxide particles, the thickness of the starch film is 0.2 mm, to obtain the coated alkali, and the particle diameter of the coated alkali is 2 mm;

[0024] (2) Mix 40 parts by weight of isobutylidene biurea, 30 parts of bamboo charcoal powder, 5 parts of coated alkali, 40 parts of cement and 20 parts of water, mix and stir evenly, and granulate into spherical shape, bake at 40-70 ℃. Dried to obtain controllable slow-release fertilizer, and the particle diameter of the controllable slow-release fertilizer is 4 mm.

[0025] Wherein, in above-mentioned preparation method, the specific surface area of bamboo charcoal powder is 300-320m 2 / Kg; cement is portland cement, its specific surface area is 380-420m 2 / Kg.

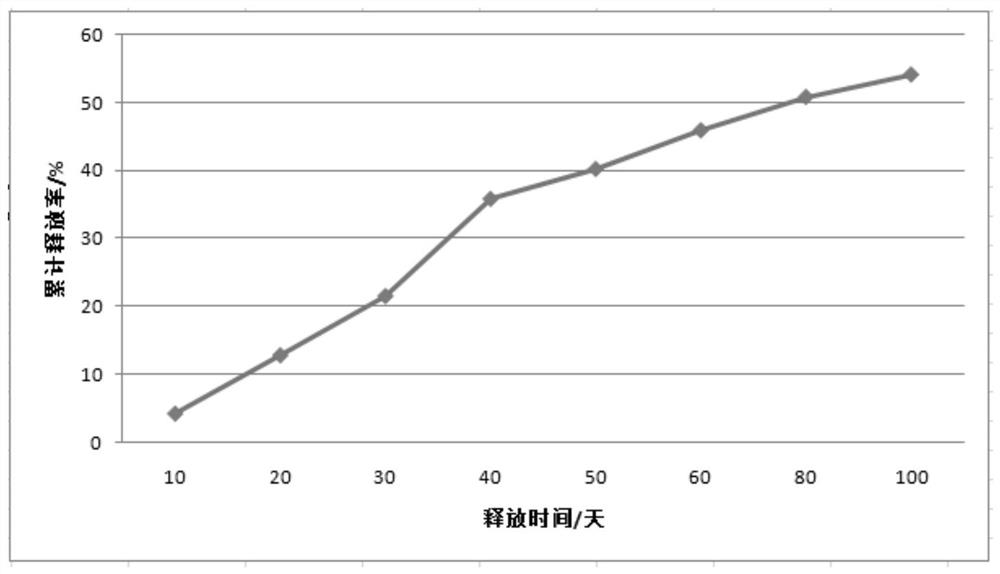

Embodiment 2

[0027] A controllable slow-release fertilizer, the preparation method of which comprises the following steps:

[0028] (1) Wrap a layer of soluble starch film on the surface of sodium hydroxide granules, the thickness of the starch film is 1 mm, to obtain the coated alkali, and the particle diameter of the coated alkali is 4 mm;

[0029] (2) Mix 70 parts by weight of isobutylidene biurea, 50 parts of bamboo charcoal powder, 10 parts of coated alkali, 70 parts of cement and 30 parts of water, mix and stir evenly, and granulate into spherical shape, bake at 40-70 ℃. Dried to obtain controllable slow-release fertilizer, and the particle diameter of the controllable slow-release fertilizer is 10 mm.

[0030] Wherein, in above-mentioned preparation method, the specific surface area of bamboo charcoal powder is 300-320m 2 / Kg; cement is portland cement, its specific surface area is 380-420m 2 / Kg.

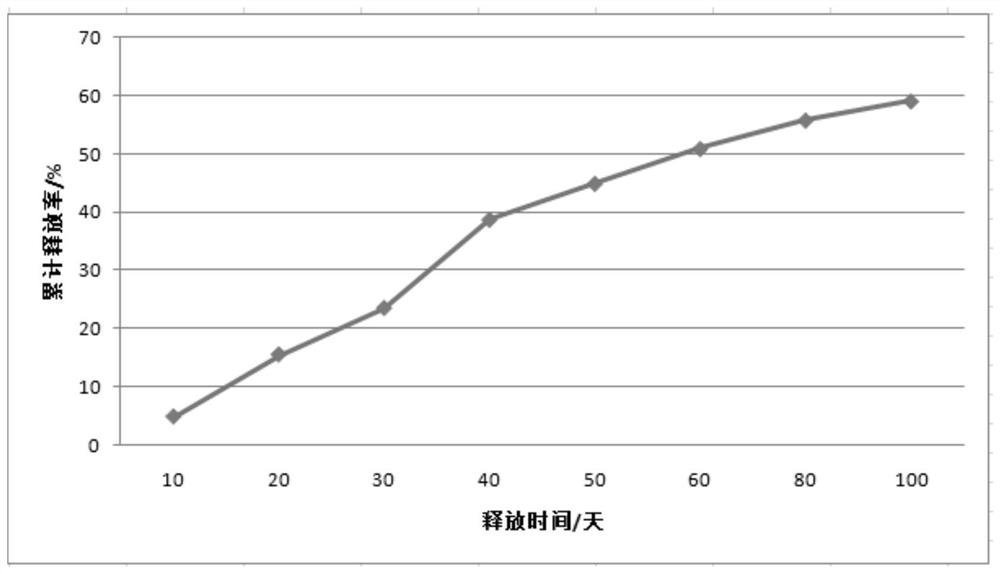

Embodiment 3

[0032] A controllable slow-release fertilizer, the preparation method of which comprises the following steps:

[0033] (1) Wrap a layer of soluble starch film on the surface of sodium hydroxide particles, the thickness of the starch film is 0.5mm, to obtain the coated alkali, and the particle diameter of the coated alkali is 3mm;

[0034] (2) Mix 55 parts by weight of isobutylidene biurea, 30 parts of bamboo charcoal powder, 8 parts of coated alkali, 55 parts of cement and 25 parts of water, mix and stir evenly, and granulate into spherical shape, bake at 40-70 ℃. Dried to obtain controllable slow-release fertilizer, and the particle diameter of the controllable slow-release fertilizer is 6 mm.

[0035] Wherein, in above-mentioned preparation method, the specific surface area of bamboo charcoal powder is 300-320m 2 / Kg; cement is portland cement, its specific surface area is 380-420m 2 / Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com