Slow-release fertilizer for saline-alkali land and preparation method thereof

A saline-alkali land and slow-release fertilizer technology, which is applied in nitrogen fertilizer, fertilization equipment, organic fertilizer, etc., can solve the problems of difficult release of isobutylidene diurea fertilizer and difficult growth of crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

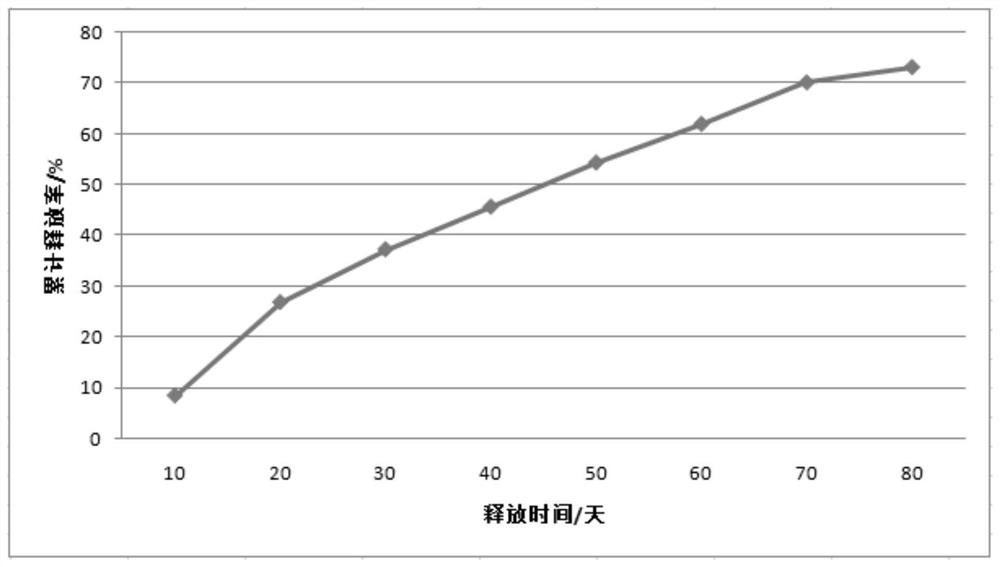

Embodiment 1

[0021] A slow-release fertilizer for saline-alkali land, the preparation method of which comprises the following steps:

[0022] (1) Wrap a layer of soluble starch film on the surface of the boric acid granules, the thickness of the starch film is 0.2mm, to obtain the coated base, and the particle diameter of the coated base is 2mm;

[0023] (2) Mix 40 parts by weight of isobutylidene diurea, 30 parts of bamboo charcoal powder, 5 parts of coated acid, 20 parts of starch and 20 parts of water, stir evenly, granulate into spherical shape, bake at 40-70 °C Dry to obtain the saline-alkali slow-release fertilizer, and the particle diameter of the saline-alkali slow-release fertilizer is 4mm.

[0024] Wherein, in the above-mentioned preparation method, the specific surface area of the bamboo charcoal powder is 300-320m2 / Kg.

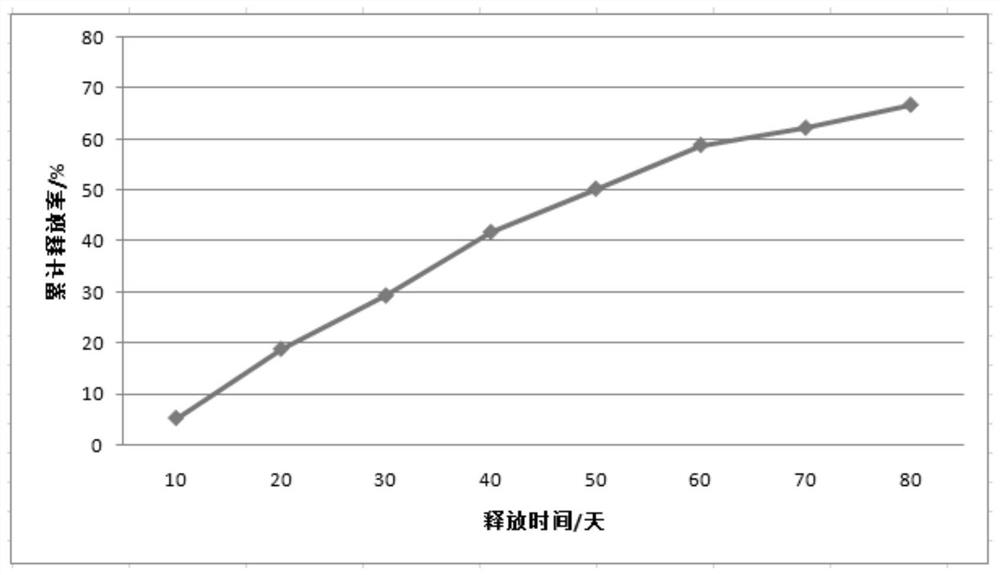

Embodiment 2

[0026] A slow-release fertilizer for saline-alkali land, the preparation method of which comprises the following steps:

[0027] (1) Wrap a layer of soluble starch film on the surface of the boric acid granules, the thickness of the starch film is 1mm, to obtain the coated alkali, the particle diameter of the coated alkali is 4mm;

[0028] (2) Mix 70 parts by weight of isobutylidene diurea, 50 parts of bamboo charcoal powder, 10 parts of coated acid, 30 parts of starch and 30 parts of water, stir evenly, and granulate into spherical shape, bake at 40-70°C dry to obtain the saline-alkali slow-release fertilizer, and the particle diameter of the saline-alkali slow-release fertilizer is 8mm.

[0029] Wherein, in the above-mentioned preparation method, the specific surface area of the bamboo charcoal powder is 300-320m2 / Kg.

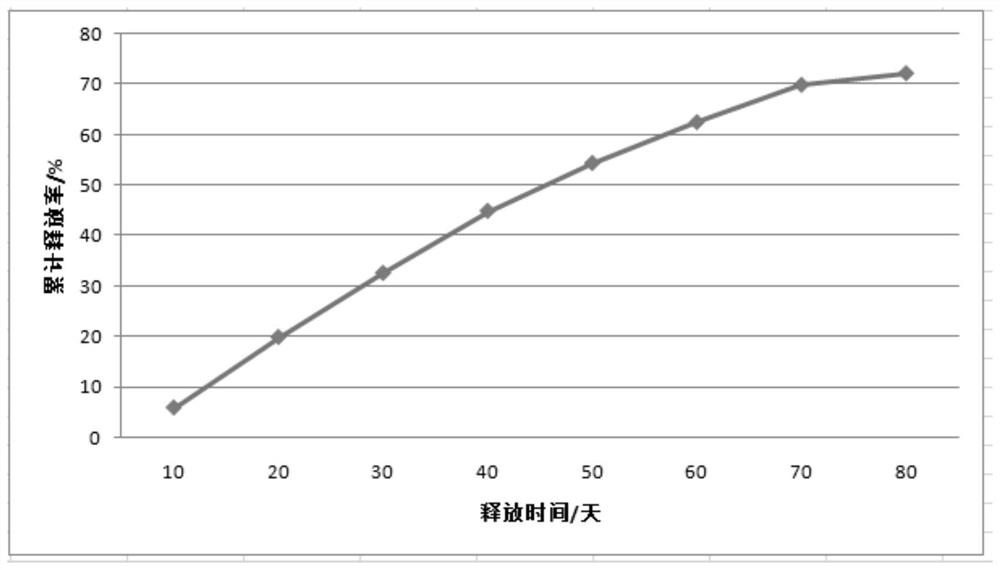

Embodiment 3

[0031] A slow-release fertilizer for saline-alkali land, the preparation method of which comprises the following steps:

[0032] (1) Wrap a layer of soluble starch film on the surface of the boric acid granules, the thickness of the starch film is 0.5mm, to obtain the coated alkali, the particle diameter of the coated alkali is 3mm;

[0033] (2) Mix 55 parts by weight of isobutylidene diurea, 40 parts of bamboo charcoal powder, 7 parts of coated acid, 25 parts of starch and 25 parts of water, stir evenly, and granulate into spherical shape, bake at 40-70 °C dry to obtain the saline-alkali slow-release fertilizer, and the particle diameter of the saline-alkali slow-release fertilizer is 5mm.

[0034] Wherein, in the above-mentioned preparation method, the specific surface area of the bamboo charcoal powder is 300-320m2 / Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com