Double-layer coated precise controllable slow-release fertilizer and preparation method thereof

A double-layer coating, controlled and slow-release technology, which is applied in the direction of layered/coated fertilizers, inorganic fertilizers, fertilizer mixtures, etc., can solve the problems of difficult control of the slow-controlled release period, and reduce the dependence on the uniformity of the film layer , easy large-scale application, the effect of reducing production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

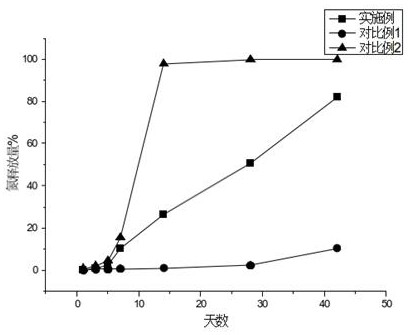

Examples

Embodiment 1

[0035] (1) Mix potassium chloride, urea, and calcium phosphate fertilizer according to the ratio of 1:1:1 and prefabricate them evenly into particles with a particle size of about 3mm; put them into fluidized bed coating equipment, preheat at 55°C for 12 minutes, and put The polyacrylic acid emulsion water-absorbing resin emulsion is sprayed on the surface of the fertilizer and dried, and by controlling the amount of the polyacrylic acid emulsion water-absorbing resin emulsion, a water-absorbing resin-coated fertilizer with a thickness of 95-150 μm is obtained;

[0036] (2) Dissolve the recovered polystyrene foam and toluene at a mass ratio of 1:5 to form a bonding solution, then add silica sol, calcium-based bentonite, and monoglyceride to emulsify at high speed to obtain a hydrophobic resin coating solution; The mass concentration is 15%, and the addition amount is 80% of the binding liquid; the calcium-based bentonite addition is 10% of the binding liquid mass, and the monog...

Embodiment 2

[0038] (1) Mix potassium chloride, urea, and calcium phosphate fertilizer according to the ratio of 1:1:1 and prefabricate them evenly into particles with a particle size of about 3mm; put them into fluidized bed coating equipment, preheat at 55°C for 12 minutes, and put The polyacrylic acid emulsion water-absorbing resin emulsion is sprayed on the surface of the fertilizer, and dried, and by controlling the amount of the polyacrylic acid emulsion water-absorbing resin emulsion, a water-absorbing resin-coated fertilizer with a thickness of 300-400 μm is obtained;

[0039] (2) Dissolve the recovered polystyrene foam and toluene at a mass ratio of 1:5 to form a bonding solution, then add silica sol, calcium-based bentonite, and monoglyceride to emulsify at high speed to obtain a hydrophobic resin coating solution; The mass concentration is 15%, and the addition amount is 80% of the binding liquid; the calcium-based bentonite addition is 10% of the binding liquid mass, and the mon...

Embodiment 3

[0041] (1) Mix potassium chloride, urea, and calcium phosphate fertilizer according to the ratio of 1:1:1 and prefabricate them evenly into particles with a particle size of about 3mm; put them into fluidized bed coating equipment, preheat at 55°C for 12 minutes, and put The polyacrylic acid emulsion water-absorbing resin emulsion is sprayed on the surface of the fertilizer, and dried, and by controlling the amount of the polyacrylic acid emulsion water-absorbing resin emulsion, a water-absorbing resin-coated fertilizer with a thickness of 200-300 μm is obtained;

[0042] (2) Dissolve the recovered polystyrene foam and toluene at a mass ratio of 1:5 to form a bonding solution, then add silica sol, calcium-based bentonite, and monoglyceride to emulsify at high speed to obtain a hydrophobic resin coating solution; The mass concentration is 15%, and the addition amount is 80% of the binding liquid; the calcium-based bentonite addition is 10% of the binding liquid mass, and the mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com