Preparation method of liquid water-soluble fertilizer

A water-soluble fertilizer technology, applied in liquid fertilizers, organic fertilizers, nitrate fertilizers, etc., can solve problems such as the inability to improve soil caking, the inability to supplement medium and trace elements at the same time, and the inability to improve crop stress resistance. , to achieve the effects of improving product quality, increasing yield, and preventing soil agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

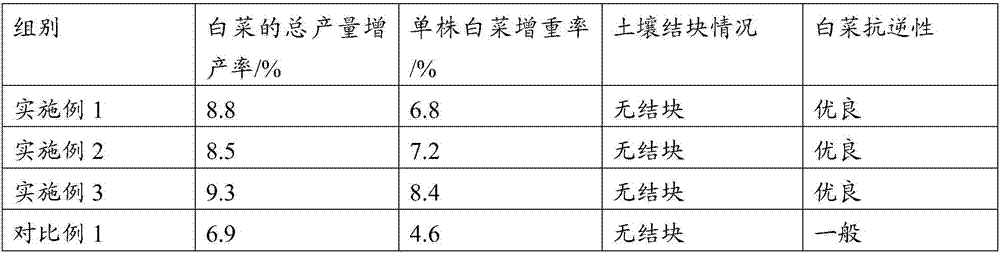

Examples

Embodiment 1

[0019] A kind of preparation method of liquid water-soluble fertilizer, described preparation method comprises the following steps:

[0020] Step 1. Weigh 40 parts by mass of calcium nitrate and add it to 50 parts by mass of water, fully stirring until fully dissolved;

[0021] Step 2. Add 2 parts by mass of copper sulfate, 1 part by mass of magnesium nitrate, 3 parts by mass of zinc sulfate, 2 parts by mass of ferrous sulfate monohydrate, 12 parts by mass of dodecylbenzenesulfonic acid in the calcium nitrate solution prepared in step 1 Sodium and 2 parts by mass of cross-linked polyvinylpyrrolidone, stirred at 60°C for 15 minutes;

[0022] Step 3. Use a metering pump to pump the stirred mixture prepared in Step 2 into the reactor, add 0.5 parts by mass of 2-hydroxypropane-1,2,3-tricarboxylate iron while stirring, and stir at 80°C 30min, then cool down to 52°C, keep warm for 6h, after the reaction is over, cool down to room temperature for later use;

[0023] Step 4. The mat...

Embodiment 2

[0025] A kind of preparation method of liquid water-soluble fertilizer, described preparation method comprises the following steps:

[0026] Step 1. Take 55 parts by mass of calcium nitrate and add it to 60 parts by mass of water, and stir until completely dissolved;

[0027] Step 2. Add 5 parts by mass of copper sulfate, 3 parts by mass of magnesium nitrate, 5 parts by mass of zinc sulfate, 4 parts by mass of ferrous sulfate monohydrate, 15 parts by mass of tetradecylbenzenesulfonic acid in the calcium nitrate solution prepared in step 1 Sodium and 4 parts by mass of cross-linked polyvinylpyrrolidone, stirred at a temperature of 70° C. for 20 minutes;

[0028] Step 3. Use a metering pump to pump the stirred mixture prepared in Step 2 into the reactor, add 2.5 parts by mass of 2-hydroxypropane-1,2,3-tricarboxylate iron while stirring, and stir at 90°C 45min, then cool down to 55°C, keep warm for 7h, cool down to room temperature after the reaction is over;

[0029] Step 4. S...

Embodiment 3

[0031] A kind of preparation method of liquid water-soluble fertilizer, described preparation method comprises the following steps:

[0032] Step 1. Take 50 parts by mass of calcium nitrate and add it to 55 parts by mass of water, and stir until completely dissolved;

[0033] Step 2. Add 3.5 parts by mass of copper sulfate, 2 parts by mass of magnesium nitrate, 4 parts by mass of zinc sulfate, 3 parts by mass of ferrous sulfate monohydrate, 13 parts by mass of surfactant and 3 parts by mass of calcium nitrate solution prepared in step 1. Cross-linked polyvinylpyrrolidone, stirred at 65°C for 18min;

[0034] Step 3. Use a metering pump to pump the stirred mixture prepared in Step 2 into the reactor, add 2 parts by mass of 2-hydroxypropane-1,2,3-tricarboxylate iron while stirring, and stir at 85°C 35min, then cool down to 54°C, keep warm for 6h, after the reaction, cool down to room temperature for later use;

[0035] Step 4. The material cooled to room temperature in the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com