Polyimide film with pyrimidine side groups and preparation method of polyimide film

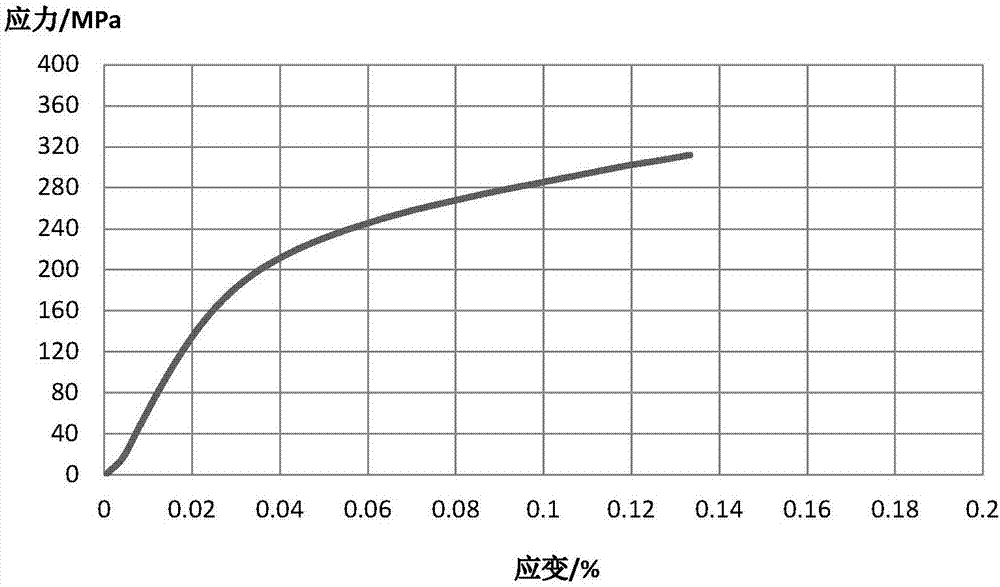

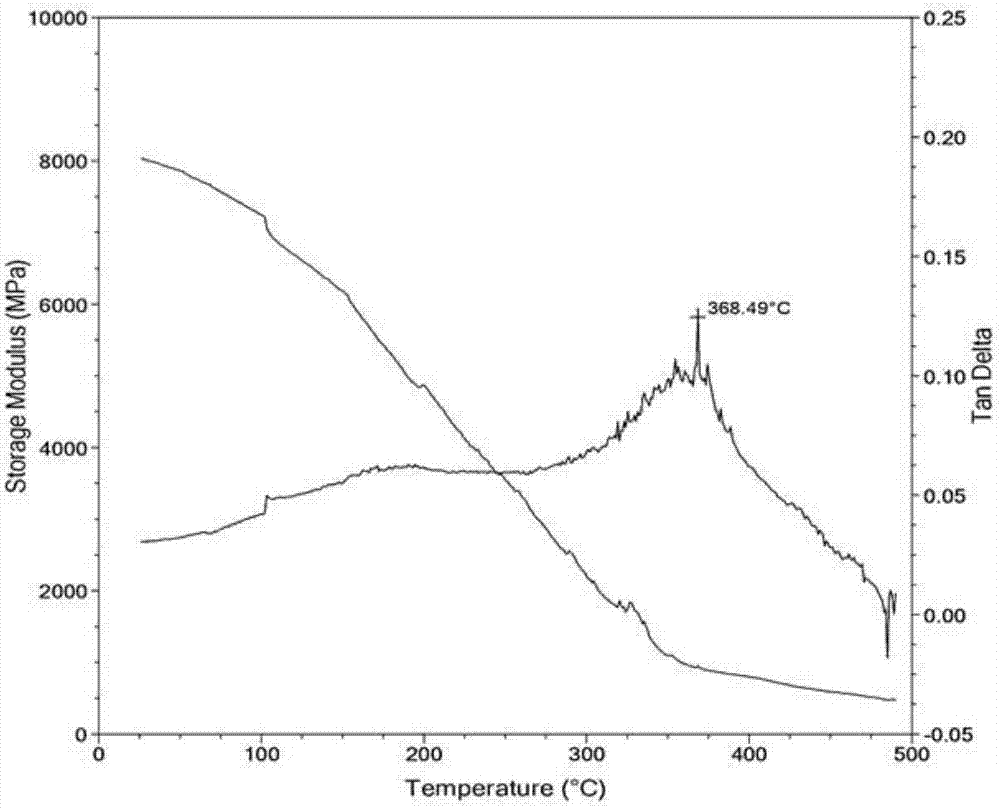

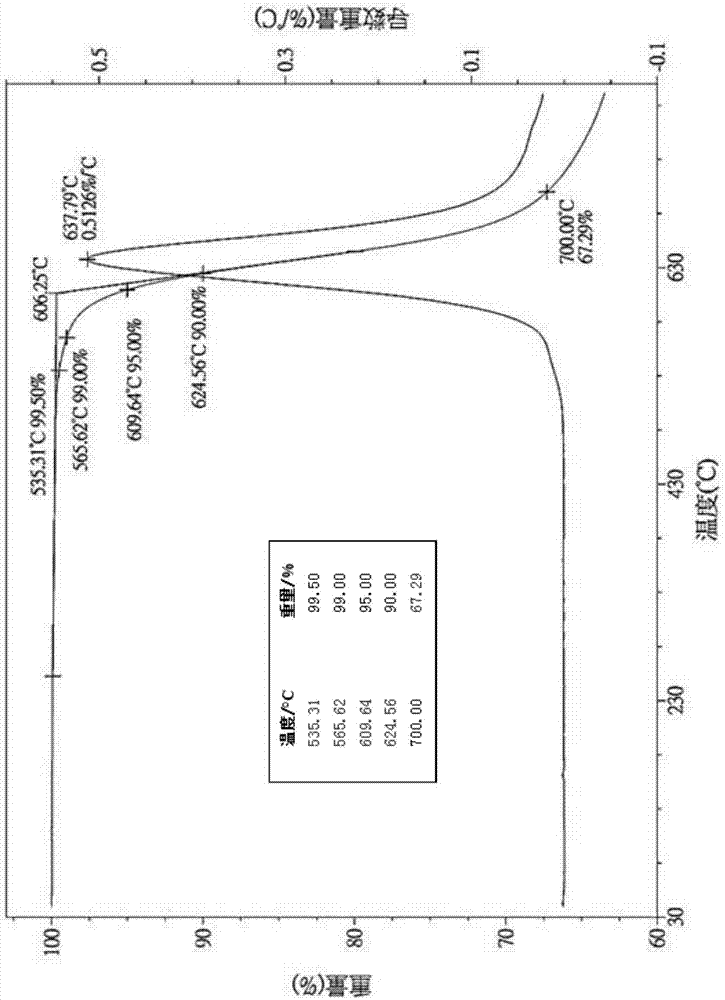

The technology of polyimide film and polyamic acid is applied in the field of polyimide film with pyrimidine side group and its preparation field, which can solve the problems of high rigidity of molecular chain, low elongation at break, poor flexibility, etc. Effects of high modulus, reduced bulk density, and increased elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] At -15°C, p-phenylenediamine (10.8g, 0.1mol) and N-(2-pyrimidinyl)-2-(3-aminophenyl)-5-aminoindole (15.05g, 0.05mol) Dissolve the mixed diamine in 180g of strictly dry NMP, protect it under nitrogen, stir it mechanically until it is completely dissolved, and then add aromatic dianhydride {(aromatic dianhydride is a commercially available product), and the aromatic dianhydride is selected from 1, 2, 4 , 5-Pyromellitic dianhydride, the addition amount is (32.7g, 0.15mol) Continue stirring for 18h under the protection of nitrogen to obtain a polyamic acid solution.

[0044] After decompressing the above polyamic acid solution to eliminate air bubbles, apply it on clean glass with a film thickness of 150 microns, put it in an oven, and heat it to cure at 80°C for 360 minutes, 170°C for 60 minutes, and 230°C for 60 minutes. Cured at 300°C for 120 minutes, evaporated to remove the solvent, then cooled down to room temperature naturally, and peeled off to obtain a film.

Embodiment 2

[0045] Embodiment 2: In the implementation process, except that the aromatic dianhydride is selected from 3,3'-4,4'-biphenyl dianhydride, and its addition amount is different (44.1g, 0.15mol), the rest are the same as in Example 1.

Embodiment 3

[0046] Embodiment 3: In the implementation process, except that the aromatic dianhydride is selected from 3,3'-4,4'-diphenyl ether dianhydride, and its addition amount is different (46.5g, 0.15mol), the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com