Modified phenolic resin foam plastic and preparation and application thereof

A technology of phenolic resin and foam plastics, which is applied in the field of thermal insulation materials, can solve the problems of poor strength of modified foam and achieve the effects of reducing loss, good thermal insulation effect and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

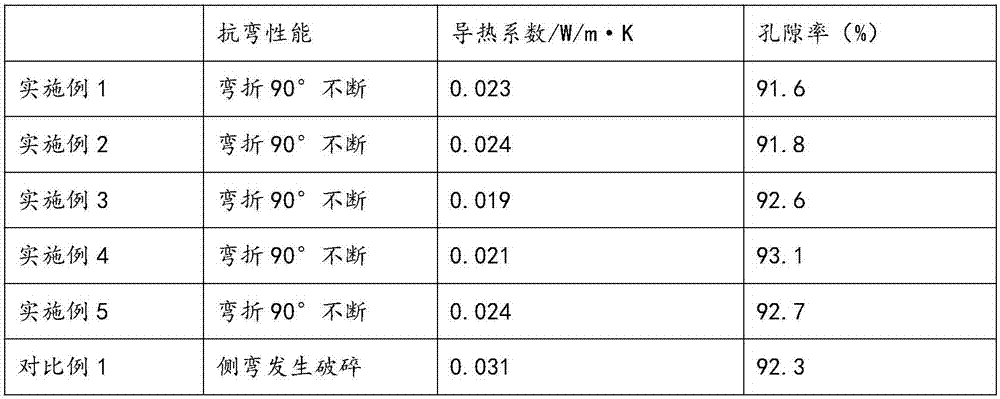

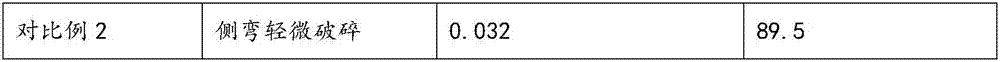

Examples

Embodiment 1

[0023] Embodiment 1: a kind of modified phenolic resin foamed plastics, comprises bamboo fiber 5.2g, lignin calcium sulfate 24g, polymer 36g, phenol 52g, silicone oil surfactant 2g phenolsulfonic acid 5g, n-pentane 2g.

[0024] A method for making modified phenolic resin foam, comprising the following steps:

[0025] S1: Oxidative degradation of lignin, first add lignin calcium sulfate to water of equal weight, then add sodium hydroxide solution (30%) to pH 10.2, add hydrogen peroxide to react, and finally neutralize with dilute hydrochloric acid to pH 2. Take out the precipitate and wash and filter;

[0026] S2: After mixing the surfactant, acid curing agent, phenol and lignin, react at a temperature of 23°C and a pressure of 2MPa, and obtain a solution of lignin phenolization products after the reaction;

[0027] S3: Add bamboo fiber and foaming agent to the solution of lignin phenolization products in S2, then add formaldehyde, react at 60°C for 2h, then react at 90°C for ...

Embodiment 2

[0028] Embodiment 2: a kind of modified phenolic resin foamed plastics, including bamboo fiber 6g, lignin calcium sulfate 24g, paraformaldehyde 36g, phenol 60g, Tween surfactant 5g, xylenesulfonic acid 10g, isopentane 5g.

[0029] A method for making modified phenolic resin foam, comprising the following steps:

[0030] S1: Oxidative degradation of lignin, first add lignin calcium sulfate to water of equal weight, then add sodium hydroxide solution (30%) to pH 10.2, add hydrogen peroxide to react, and finally neutralize with dilute hydrochloric acid to pH 2. Take out the precipitate and wash and filter;

[0031] S2: After mixing the surfactant, acid curing agent, phenol and lignin, react at a temperature of 300° C. and a pressure of 5 MPa, and obtain a solution of lignin phenolization products after the reaction;

[0032] S3: Add bamboo fiber and foaming agent to the solution of lignin phenolization products in S2, then add formaldehyde, react at 70°C for 2-4h, then react at...

Embodiment 3

[0033] Embodiment 3: a kind of modified phenolic resin foamed plastics, including bamboo fiber 5.6g, lignin calcium sulfate 19.85g, paraformaldehyde 31.25g, phenol 56g, polyether modified siloxane surfactant 3.5g, p-toluenesulfonic acid 7.5g, isopentane, 3.5g.

[0034] A method for making modified phenolic resin foam, comprising the following steps:

[0035] S1: Oxidative degradation of lignin, first add lignin calcium sulfate to water of equal weight, then add sodium hydroxide solution (30%) to pH 10.2, add hydrogen peroxide to react, and finally neutralize with dilute hydrochloric acid to pH 2. Take out the precipitate and wash and filter;

[0036] S2: After mixing the surfactant, acid curing agent, phenol and lignin, react at a temperature of 275° C. and a pressure of 3.5 MPa, and obtain a solution of lignin phenolization products after the reaction;

[0037] S3: Add bamboo fiber and foaming agent to the solution of lignin phenolization products in S2, then add formaldehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com