Solvent-less epoxy anti-corrosive paint

An epoxy anti-corrosion paint, solvent-free technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of reducing the mechanical and thermal properties of anti-corrosion paint, and achieve reduced number of constructions, strong adhesion, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A solvent-free epoxy anti-corrosion paint, composed of A component and B component, the mass ratio of A component and B component is 100:18, A component includes epoxy resin, additives, fillers, B component It is an amine curing agent;

[0022] Wherein, the epoxy resin is a mixture of bisphenol F epoxy resin and bisphenol A epoxy resin, and the mass ratio of bisphenol F epoxy resin and bisphenol A epoxy resin is 40:100;

[0023] The auxiliary agent includes leveling agent, defoamer, wetting and dispersing agent, coupling agent,

[0024] The filler is mica powder,

[0025] The amine curing agent is a cardanol modified amine curing agent,

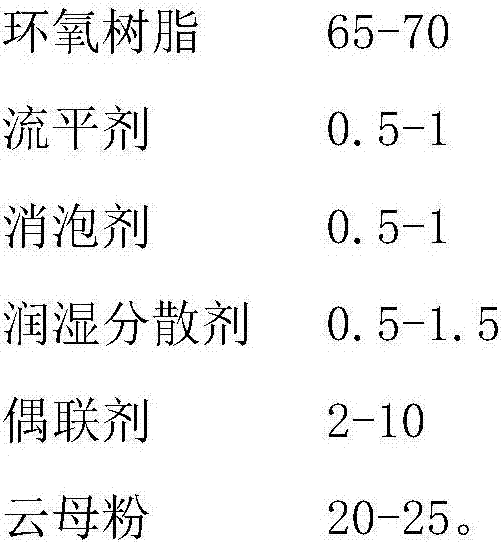

[0026] A component is as follows according to parts by weight:

[0027]

[0028]

[0029] The preparation of the A component is as follows: weigh the bisphenol F epoxy resin and the bisphenol A epoxy resin in proportion, add them to the dispersion tank, disperse for 20 minutes, add wetting and dispersing agent, defoaming agent...

Embodiment 2

[0033] A solvent-free epoxy anti-corrosion paint, composed of A component and B component, characterized in that the mass ratio of A component to B component is 100:18, A component includes epoxy resin, additives, fillers , B group is amine curing agent;

[0034] Wherein, the epoxy resin is a mixture of bisphenol F epoxy resin and bisphenol A epoxy resin, and the mass ratio of bisphenol F epoxy resin and bisphenol A epoxy resin is 50:100;

[0035] The auxiliary agent includes leveling agent, defoamer, wetting and dispersing agent, coupling agent,

[0036] The filler is mica powder,

[0037] The amine curing agent is a cardanol modified amine curing agent,

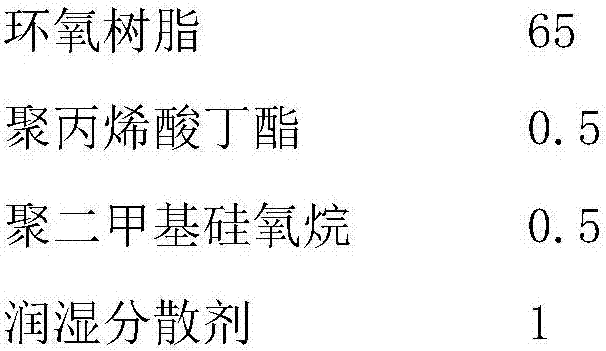

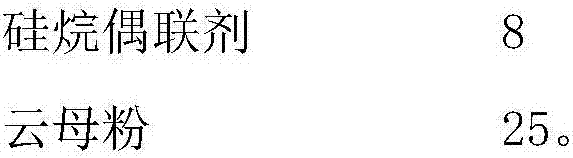

[0038] A component is as follows according to parts by weight:

[0039]

[0040] As preferably, the preparation of the A component: weigh the bisphenol F type epoxy resin and the bisphenol A type epoxy resin in proportion, add them to the dispersion tank, and after dispersing for 20 minutes, add the wetting and disper...

Embodiment 3

[0044] A solvent-free epoxy anti-corrosion paint, composed of A component and B component, characterized in that the mass ratio of A component to B component is 100:18, A component includes epoxy resin, additives, fillers , B group is amine curing agent;

[0045] Wherein, the epoxy resin is a mixture of bisphenol F epoxy resin and bisphenol A epoxy resin, and the mass ratio of bisphenol F epoxy resin and bisphenol A epoxy resin is 30:100;

[0046] The auxiliary agent includes leveling agent, defoamer, wetting and dispersing agent, coupling agent,

[0047] The filler is mica powder,

[0048] The amine curing agent is a cardanol modified amine curing agent,

[0049] A component is as follows according to parts by weight:

[0050]

[0051] Preferably, the preparation of the A component: weigh the bisphenol F epoxy resin and the bisphenol A epoxy resin in proportion, add them to the dispersion tank, disperse for 20 minutes, add the wetting and dispersing agent, For defoamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com