Combined construction process of rubber waterproof paint and non-curing rubber asphalt waterproof paint

A kind of asphalt waterproof coating and non-curing rubber technology, which is applied in the direction of anti-corrosion coating, fire-proof coating, asphalt coating, etc., can solve the problems such as places where fire prevention and explosion protection cannot be applied, and pollute the environment, and achieve safety without fire risk, excellent waterproof performance, The effect of increasing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

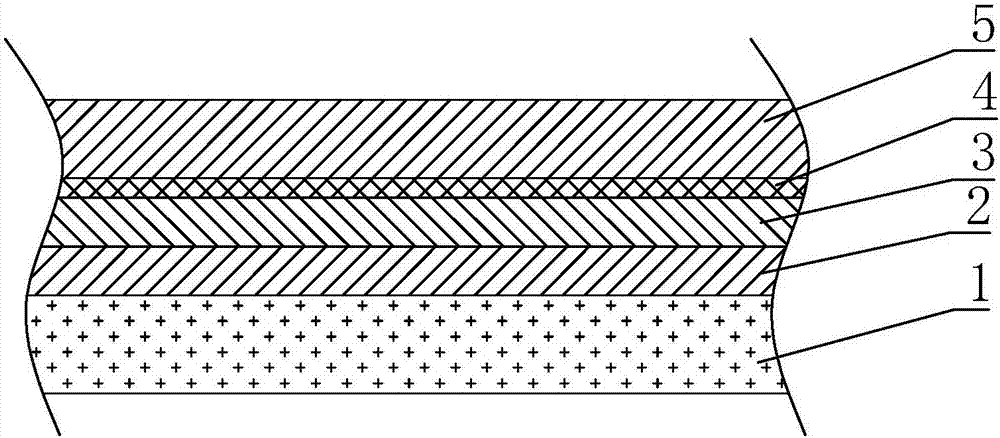

[0064] Such as figure 1 Shown, a kind of rubber waterproof coating and non-cured rubber asphalt waterproof coating composite construction technology, comprises the following steps:

[0065] a. Clean up the base layer 1 and restore it to be smooth, so as to achieve clean and clear water;

[0066] b. Evenly scrape and coat a layer of 1mm thick rubber waterproof paint on the surface of the cleaned base layer 1 as the base layer 2;

[0067] c. Evenly scrape and coat a layer of 1mm thick non-curing rubber asphalt waterproof coating layer 3 on the surface of the bottom layer 2;

[0068] d. Lay a layer of grid cloth 4 on the surface of the non-cured rubber asphalt waterproof coating layer 3;

[0069] e. On the surface of the non-cured rubber asphalt waterproof coating layer 3 paved with grid cloth 4, evenly scrape and coat a layer of rubber waterproof coating with a thickness of 2mm as the surface layer 5.

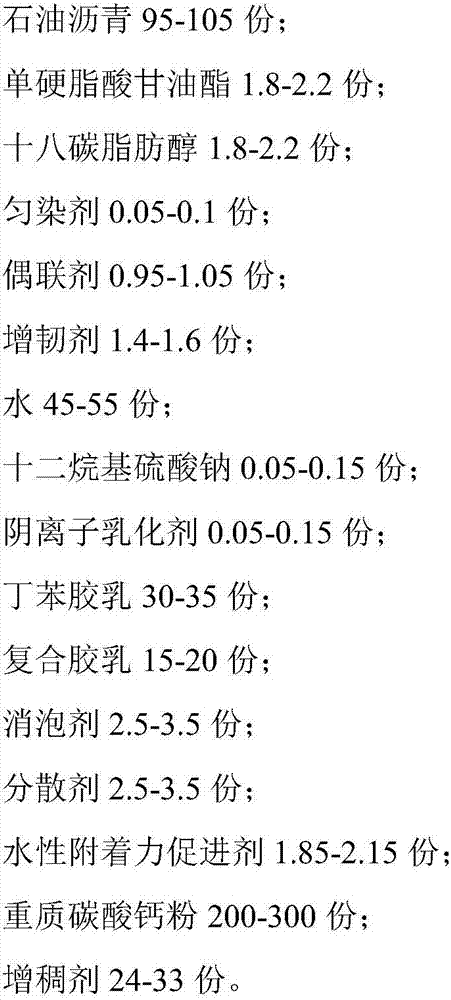

[0070] Wherein, each component of rubber waterproof coating and its corre...

Embodiment 2-11

[0081] Example 2-11: A composite construction process of rubber waterproof coating and non-cured rubber asphalt waterproof coating, the difference from Example 1 is that the components of the rubber waterproof coating and their corresponding parts by weight are shown in Table 1 shown.

[0082] Each component of rubber waterproof coating and parts by weight thereof in table 1 embodiment 1-11

[0083]

[0084]

Embodiment 12-22

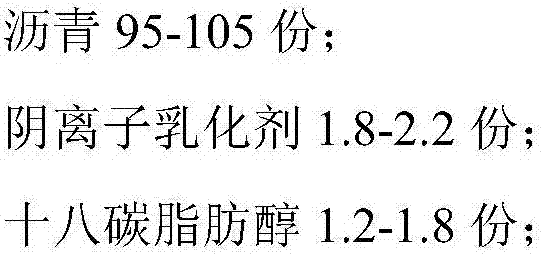

[0085] Example 12-22: A composite construction process of rubber waterproof coating and non-cured rubber asphalt waterproof coating, the difference from Example 3 is that the components of the rubber waterproof coating and their corresponding parts by weight are shown in Table 2 shown.

[0086] Each component of rubber waterproof coating and parts by weight thereof in table 2 embodiment 12-22

[0087]

[0088]

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com