Preparation method of high-Al magnesium alloy and high-Al magnesium alloy extruded bars

A magnesium alloy and rod technology, applied in the field of material preparation, can solve the problem that the mechanical properties and corrosion properties of the alloy cannot be balanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

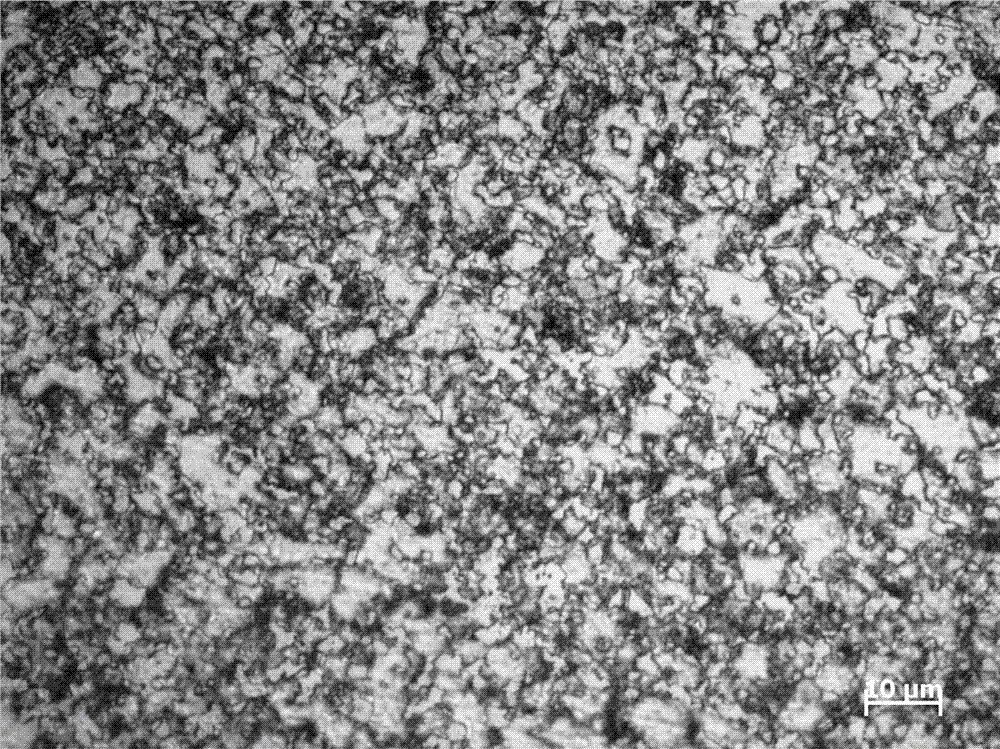

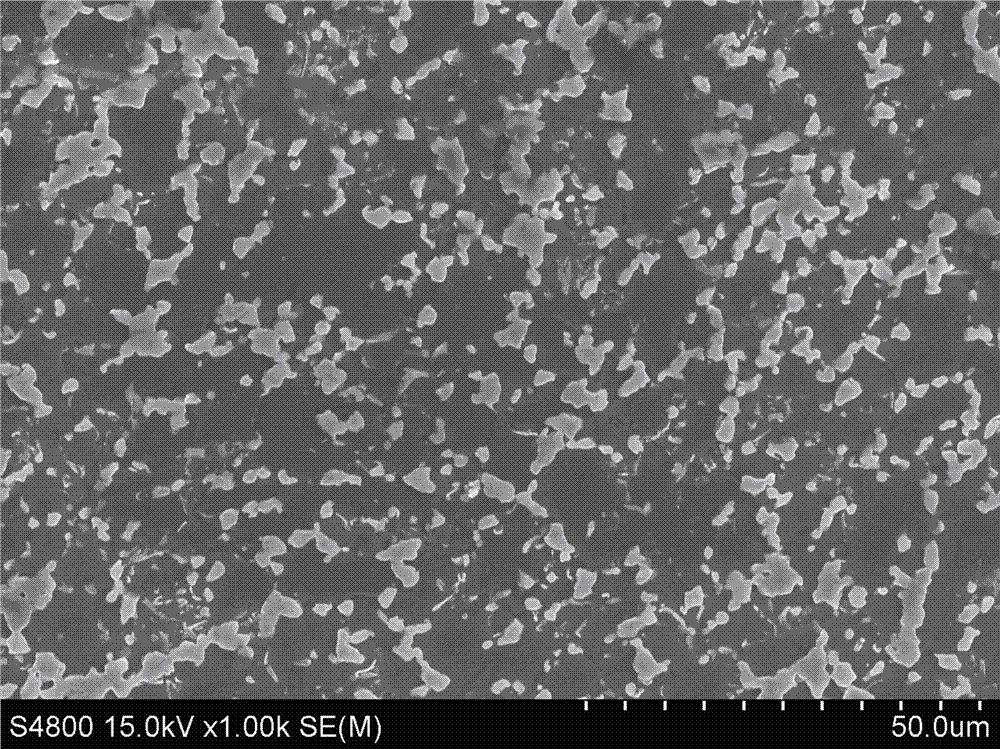

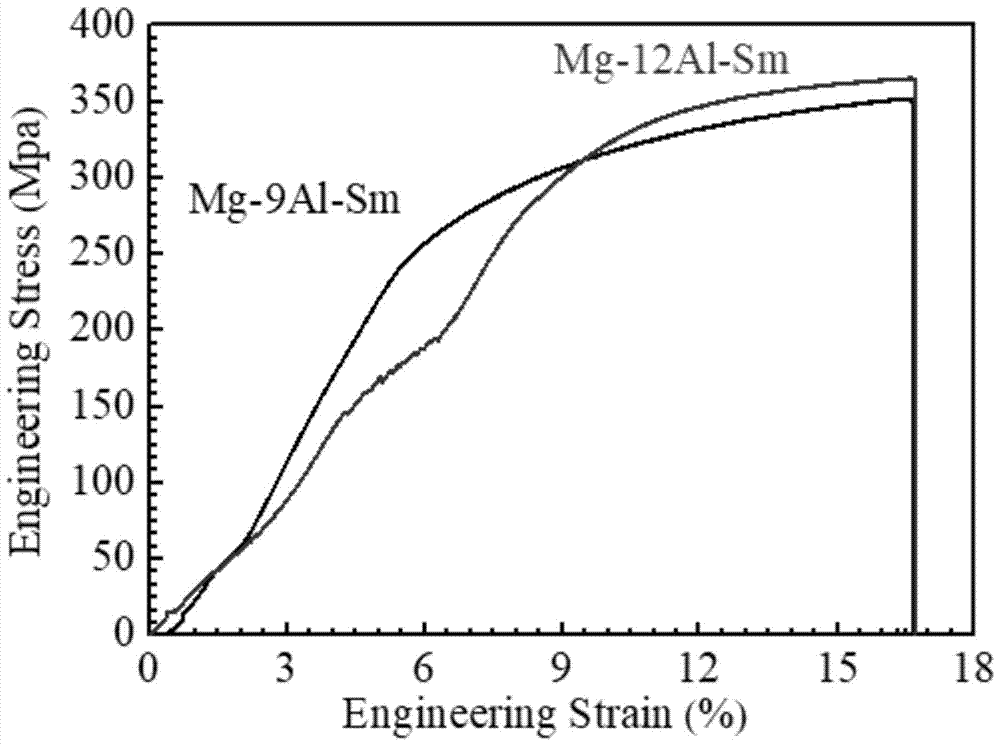

Image

Examples

Embodiment 1

[0034] A method for preparing a high Al magnesium alloy and a high Al magnesium alloy extruded rod, comprising the steps of:

[0035] (1) Selection of chemical substances and materials

[0036] The quality and purity of the chemical substances used are controlled as follows:

[0037] High-purity magnesium ingot: solid solid 99.91%;

[0038] High-purity aluminum ingot: solid solid 99.92%;

[0039] Magnesium samarium (Mg-50%Sm) master alloy: solid solid 99.97%;

[0040] (2) Melting and casting of high Al magnesium alloy

[0041] ① Preparation of open and close mold

[0042] Prepare a split mold with stainless steel material, the cavity is cylindrical, its diameter is 100mm, and a filter is added at the pouring port;

[0043] ② alloy casting

[0044] Turn on the smelting furnace, preheat the crucible to 602°C, and after the crucible turns dark red, sprinkle 103g of molten salt covering agent on the crucible wall and its bottom, add 7.8kg of high-purity magnesium blocks weig...

Embodiment 2

[0057] A method for preparing a high Al magnesium alloy and a high Al magnesium alloy extruded rod, comprising the steps of:

[0058] (1) Selection of chemical substances and materials

[0059] The quality and purity of the chemical substances used are controlled as follows:

[0060] High-purity magnesium ingot: solid solid 99.94%;

[0061] High-purity aluminum ingot: solid solid 99.92%;

[0062] Magnesium samarium (Mg-50%Sm) master alloy: solid solid 99.96%;

[0063] (2) Melting and casting of high Al magnesium alloy

[0064] ① Preparation of open and close mold

[0065] Prepare a split mold with stainless steel material, the cavity is cylindrical with a diameter of 100mm, and add a filter screen at the pouring port;

[0066] ② alloy casting

[0067] Turn on the melting furnace and preheat the crucible to 601°C. After the crucible turns dark red, sprinkle about 100g of molten salt covering agent on the wall and bottom of the crucible, add 7.8kg of high-purity magnesium bl...

Embodiment 3

[0080] A method for preparing a high Al magnesium alloy and a high Al magnesium alloy extruded rod, comprising the steps of:

[0081] (1) Selection of chemical substances and materials

[0082] The quality and purity of the chemical substances used are controlled as follows:

[0083] High-purity magnesium ingot: solid solid 99.95%;

[0084] High-purity aluminum ingot: solid solid 99.96%;

[0085] Magnesium samarium (Mg-50%Sm) master alloy: solid solid 99.96%;

[0086] (2) Melting and casting of high Al magnesium alloy

[0087] ① Preparation of open and close mold

[0088] Prepare a split mold with stainless steel material, the cavity is cylindrical with a diameter of 100mm, and add a filter screen at the pouring port;

[0089] ② alloy casting

[0090] Turn on the smelting furnace, preheat the crucible to 598°C, and after the crucible turns dark red, sprinkle 101g of molten salt covering agent on the crucible wall and its bottom, add 7.8kg of high-purity magnesium blocks ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com