Method for controlling transient air-fuel ratio of high-power gas engine

A gas engine, air-fuel ratio technology, applied in engine control, electrical control, fuel injection control and other directions, can solve the problems of unstable mixture rich and lean, the engine cannot work stably, and the air-fuel ratio closed-loop control strategy is not perfect. Good practicability, stable work, easy to rewrite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

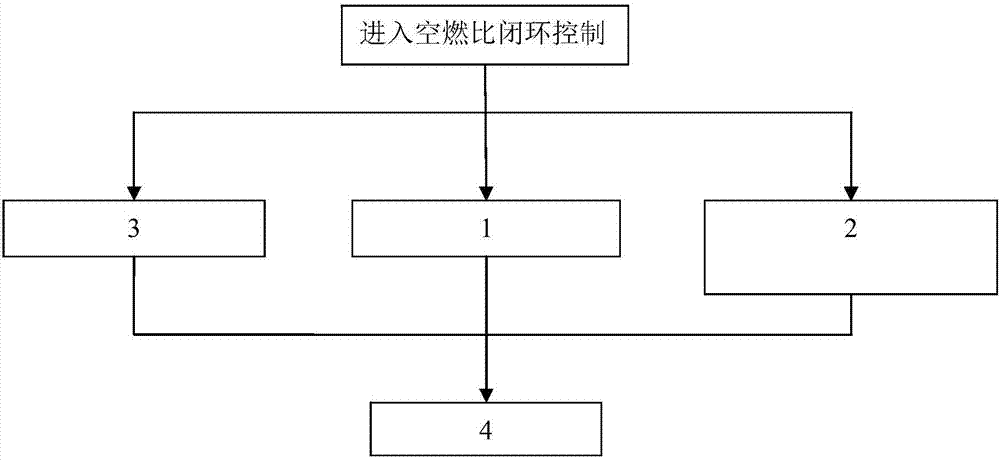

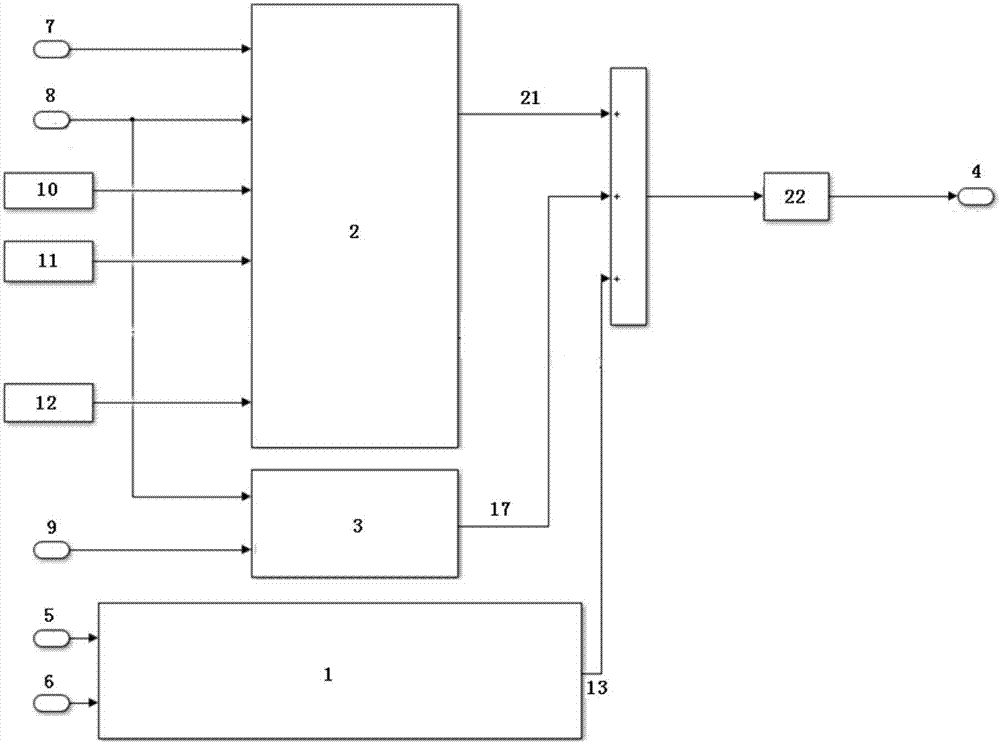

[0033] Such as figure 1 Air-fuel ratio closed-loop control flow chart and figure 2 As shown in the air-fuel ratio closed-loop control strategy model, the present invention provides a method for controlling the transient air-fuel ratio of a high-power gas engine. The control system corresponding to the method is composed of three gas quantity calculation controllers:

[0034] Construct feedforward compensation controller 1;

[0035] Adaptive learning PID feedback controller 2 based on wide-area oxygen sensor;

[0036] Basic gas volume acquisition module 3;

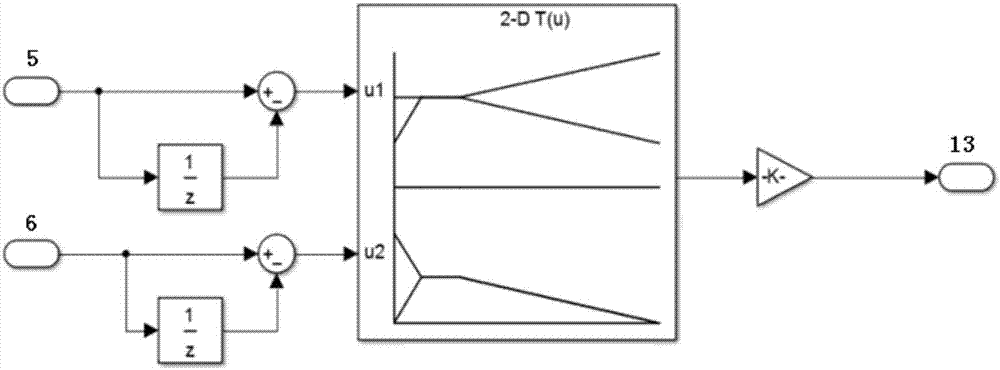

[0037] Constructing the feedforward compensation controller 1 is specifically expressed as follows,

[0038] 1. Build a feed-forward compensation controller 1 that can ensure a quick response to engine operating conditions according to the variation ΔTPS of the throttle opening 6 and the variation Δrpm of the rotational speed 5, so as to accurately increase or decrease the feed-forward control compensation gas volume 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com