A kind of preparation method of nay molecular sieve

A technology of molecular sieve and silica-alumina gel, which is applied in the direction of crystalline aluminosilicate zeolite and octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of long time-consuming depolymerization of silica gel, low utilization rate of silicon source, and high feeding water volume. Achieve clean production, save energy consumption, and improve the effect of solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides a method for preparing NaY molecular sieves, the method comprising: a. uniformly mixing a directing agent, a silicon source, an aluminum source and water to obtain a silica-alumina gel mixture, wherein, in terms of oxides and moles, the The composition of the silica-alumina gel mixture is Na 2 O: Al 2 o 3 : SiO 2 :H 2 O=(1.5-10):1:(5-18):(100-500), preferably Na 2 O: Al 2 o 3 : SiO 2 :H 2O=(2-6):1:(6-10):(150-400); b, filter the silica-alumina gel mixture obtained in step a to obtain a gel filter cake; c, filter the silica-alumina gel mixture obtained in step b The obtained gel filter cake is subjected to crystallization treatment to obtain a crystallized product; d. Washing and drying the crystallized product obtained in step c to obtain NaY molecular sieve. It should be noted that in the process of preparing the silica-alumina gel mixture in the method of the present invention, the addition of water is not particularly strictly ...

Embodiment 1

[0042] This example illustrates the preparation method of the directing agent used in the present invention.

[0043] With 378 water glass (Qilu Catalyst Company provides, SiO 2 251.5g / L, modulus 3.3, density 1260g / L) is put into the beaker, add 282g perbasic sodium metaaluminate (provided by Qilu Catalyst Company, Al 2 o 3 41g / L, Na 2 (297g / L, density 1353g / L) and 38g of water, aged at 30°C for 18 hours to obtain the directing agent. The molar ratio of the directing agent is 16.5Na 2 O: Al 2 o 3 :15SiO2 2 :350H 2 O.

Embodiment 2

[0045] This example illustrates the preparation method of the NaY molecular sieve provided by the invention.

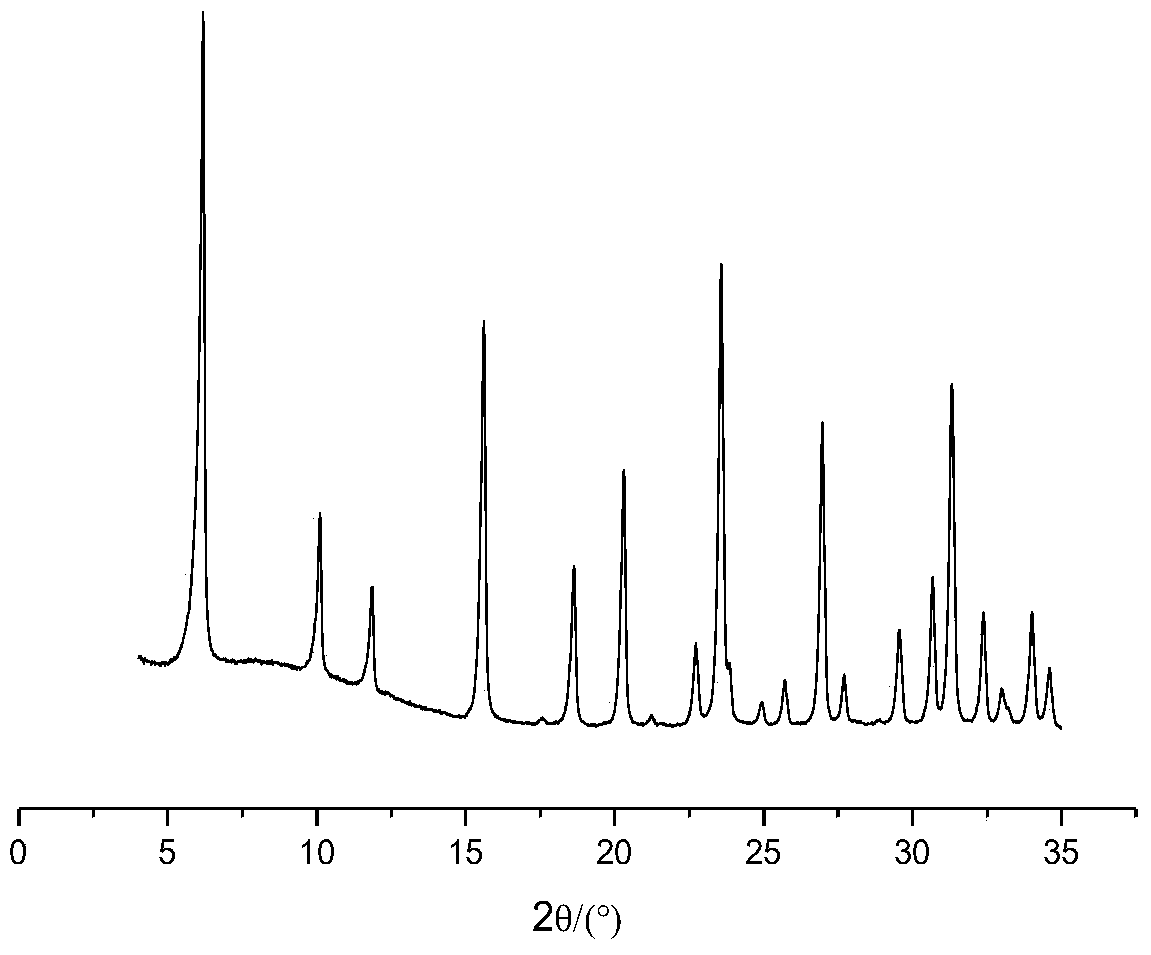

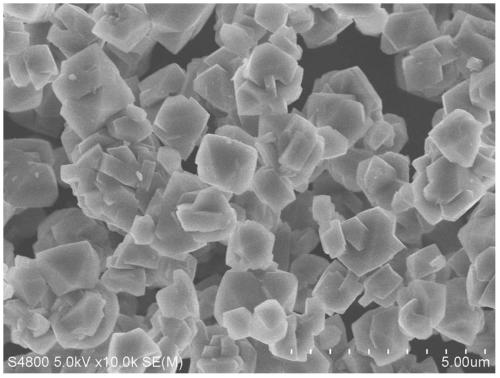

[0046] Under stirring state, to 126g water glass (provided by Qilu Catalyst Company, SiO 2 251.5g / L, modulus 3.3, density 1260g / L) add the directing agent that 25g embodiment 1 prepares, 20g aluminum sulfate solution (Qilu Catalyst Company provides, Al 2 o 3 90g / L, H 2 SO 4 259g / L, density 1277g / L), 32g low-alkali sodium metaaluminate solution (provided by Qilu Catalyst Company, Al 2 o 3 186.7g / L, Na 2 (280.8g / L, density 1405g / L) and 100g water are mixed homogeneously, and the silica-alumina gel mixture of gained is filtered in suction filter, and with the water rinse of 10 times of filter cake volume, drain, will obtain 204g gel filter cake (dry basis is 24.0%) is directly packed in the stainless steel reactor and is crystallized at 100 ℃ for 26h, and the crystallized product is through filtering, washing, and 120 ℃ of drying overnights in oven, obtains NaY...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com