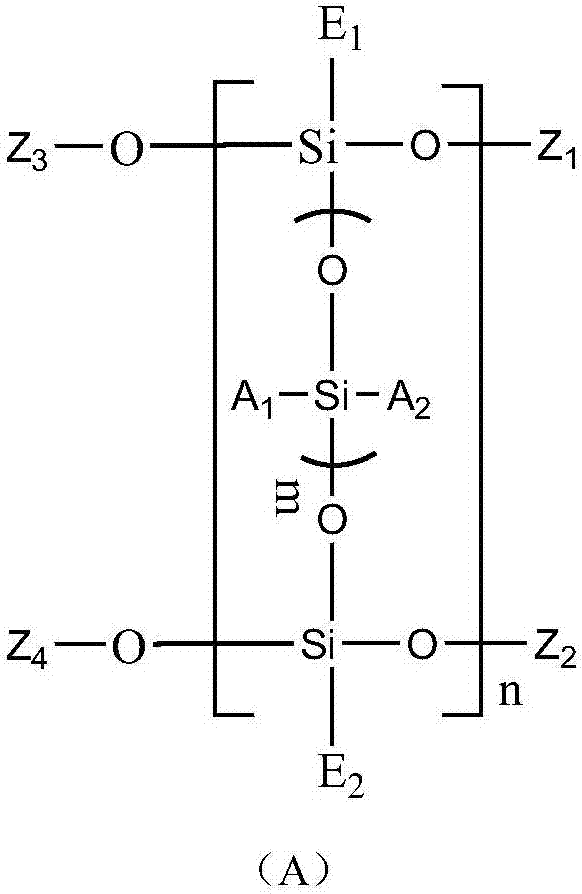

Multi-arm siloxane bridge-based trapezoidal polysiloxane copolymer and preparation method and application thereof

A polysiloxane and siloxane bridge technology, applied in the field of polymers, can solve the problems of reducing the reactivity of reactive groups and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Via triethoxysilane, diphenyldihydroxysilane, HO(MeHSiO) 100 H Preparation of Multi-Armed Siloxane Bridged Ladder Polysiloxane Copolymer.

[0095] (1) Under the protection of dry nitrogen, put 26ml (0.138 moles) of triethoxysilane and 20ml of tetrahydrofuran into a multi-necked flask equipped with a condenser tube and a dropping funnel; 10g (0.046 moles) of diphenyl Dihydroxysilane was dissolved in 20ml tetrahydrofuran, 1ml pyridine (0.0124 mol) was dissolved in 20ml tetrahydrofuran, and the two solutions were respectively placed in constant pressure dropping funnels; the solutions in the two constant pressure dropping funnels were dropped separately at -20°C Add it into a multi-neck flask, and stir; after the dropwise addition, continue to react for 2.5 hours; after stopping the reaction, distill and concentrate to remove ethanol and unreacted triethoxysilane and part of tetrahydrofuran to obtain a pure intermediate solution; adding tetrahydrofuran to the intermediate...

Embodiment 2

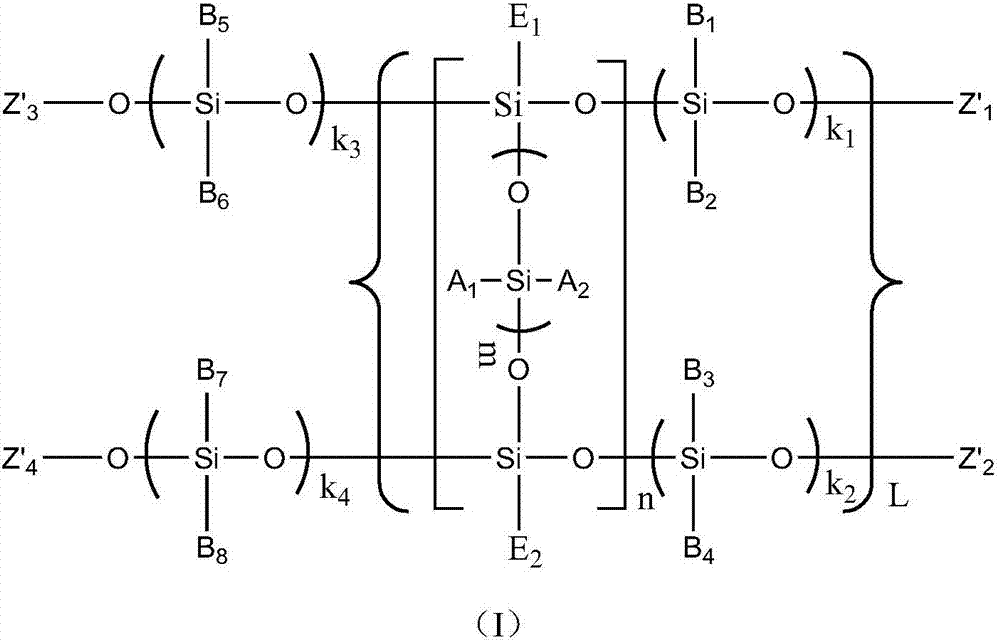

[0102] Z prepared in Example 1 1 = Z 2 = Z 3 = Z 4 The multi-arm siloxane bridging ladder polysiloxane copolymer of = H (I 1 ) with 1,1,3,3-tetramethyldisiloxane to further react to obtain multi-arm siloxane bridging ladder polysiloxane copolymer (II 1 ).

[0103] At 60°C, to the multi-arm siloxane bridging ladder polysiloxane copolymer prepared in Example 1 (I 1 ) into 0.3 g (2.2×10 -3 mol), 0.025 g (2.2×10 -4 ) sulfuric acid, 20ml tetrahydrofuran, after reacting for 7 hours, heat up to 120°C to distill tetrahydrofuran and water; then filter and separate the reaction mixture, collect the clear liquid, wash with water until neutral, concentrate, and dry under reduced pressure for purification to obtain formula (I) The shown multi-arm siloxane bridging ladder polysiloxane copolymer (II 1 ), where E 1 =E 2 = H, A 1 =A 2 = phenyl, B 1 =B3 =B 5 =B 7 = methyl, B 2 =B 4 =B 6 =B 8 = H, Z 1 = Z 2 = Z 3 = Z 4 =SiHMe 2 , Me=methyl, m=1, n=20, L=1, k 1 =k 2 =k ...

Embodiment 3

[0107] Through phenyltrimethoxysilane, diphenyldihydroxysilane, HO(Me 2 SiO) 243 H Preparation of Multi-Armed Siloxane Bridged Ladder Polysiloxane Copolymer.

[0108] (1) Under the protection of dry nitrogen, put 50ml (0.68 moles) of phenyltrimethoxysilane in a multi-necked flask equipped with a condenser tube and a dropping funnel, and dissolve 10 grams (0.046 moles) of phenyltrimethoxysilane at -20°C ) The mixed solution of diphenyldihydroxysilane and 50 grams of tetrahydrofuran was added dropwise into the multi-neck flask through the dropping funnel, and ammonia gas was introduced at the same time; after the dropwise addition, the ammonia gas flow was stopped, and the temperature was gradually raised to 70°C for 1 hour reaction To remove ammonia; after stopping the reaction, distill and concentrate to remove methanol, unreacted phenyltrimethoxysilane and part of tetrahydrofuran to obtain a pure intermediate solution; mix the intermediate solution with toluene to obtain a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending diameter | aaaaa | aaaaa |

| Bending diameter | aaaaa | aaaaa |

| Bending diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com