Recovery method for mine coalside anchor pole

A recovery method and technology for supporting bolts, which are applied in the installation of bolts, mining equipment, earth-moving drilling, etc. Safe and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0022] The 15109 coal seam 15109 fully mechanized mining face of a mine is equipped with two troughs, namely, the transport trough and the return air trough. The length of the transport trough is 767m. The non-mining side is left-handed rebar (25MnSi), Ф20×1800mm, The drilling depth of the side bolts is 1700mm, the exposure is 100mm, the row spacing is 1500mm, and there are 5 pieces in a row; the length of the return air trough is 1086m, and the side of the non-coal mining side is left-handed rebar (25MnSi), Ф20×1800mm, and the side bolts are drilled The depth is 1700mm, the exposure is 100mm, the row spacing is 1500mm, and there are 4 in a row.

Embodiment approach

[0023] This implementation mode includes the following steps:

[0024] (1) When the mine pressure does not appear, within the range of 20m ahead of the fully-mechanized mining face support, dismantle and recover the coal side support components such as the anchor tray, nuts, ladder beams and nets of the coal side resin metal anchor rod 5 in sequence; When the pressure appears, within 5m from the end of the fully mechanized mining face, dismantle the coal side supporting components such as the anchor tray, nuts, ladder beams and nets of the recycled coal side resin metal anchor 5;

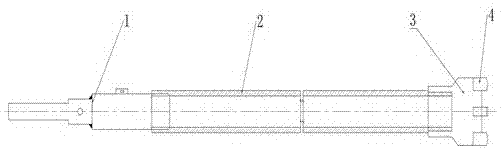

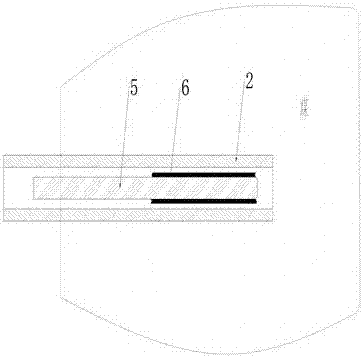

[0025] (2) Use the wet coal side resin metal bolt recovery drilling tool to directly pull out the coal side resin metal bolt. The wet coal side resin metal bolt recovery drilling tool includes a connector 1, a hollow drill pipe 2 and a hollow drill bit 3, Hollow drill bit 3 welded diamond composite sheet 4, 3 teeth, tooth width 15mm, tooth height 25mm, hollow drill pipe 2 inner diameter greater than...

Embodiment approach 2

[0028] The fully mechanized mining face of 15# coal seam 15109 in a mine needs to pass through three empty roadways in the east wing return air lane, east wing belt lane and east wing track lane. The arrangement of the coal side resin metal anchors in the three empty lanes is: The rod material is left-handed rebar (25MnSi), Ф20×1800mm, the drilling depth of the auxiliary bolt is 1700mm, the exposed 100mm, the row spacing is 1200mm, and there are 4 bolts in a row. Within the range of 20m ahead of the fully mechanized mining face, the coal side supporting components such as the anchor tray, nuts, ladder beams and nets of the recycled coal side resin metal anchors are dismantled in sequence, and the wet type coal side resin metal bolt recovery drilling tools are used to directly set them Coal side resin metal anchor rods, three empty lanes, a total of six coal side resin metal anchor rods have a good recovery effect. Others are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com