A kind of manufacturing method of fast recovery diode and fast recovery diode

A technology for recovering diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as high on-state voltage, increased device voltage drop, and reduced device performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Such as Figure 5 As shown, it is a schematic diagram of the manufacturing method of the fast recovery diode provided by Embodiment 1 of the present invention, including:

[0049] Step 101, providing a substrate.

[0050] The substrate may be an N-type substrate, that is, the substrate is formed by adding N-type impurities into the silicon material.

[0051] Step 102, forming an N-type region layer on the surface of the substrate.

[0052] After obtaining the substrate, it is necessary to form an epitaxial region layer on the substrate based on the substrate, that is, form an epitaxial region layer on the upper surface of the substrate, wherein the epitaxial region layer is an N-type region layer. The manufacturing method of the N-type regional layer is also to add N-type impurities into the silicon material.

[0053] It should be noted that the thickness of the N-type region layer is much smaller than the thickness of the substrate, and the N-type region layer here ...

Embodiment 2

[0068] Such as Figure 7 As shown, it is a schematic diagram of the manufacturing method of the fast recovery diode provided by Embodiment 2 of the present invention, including:

[0069] Step 201 , providing a substrate, and forming an N-type region layer on the surface of the substrate.

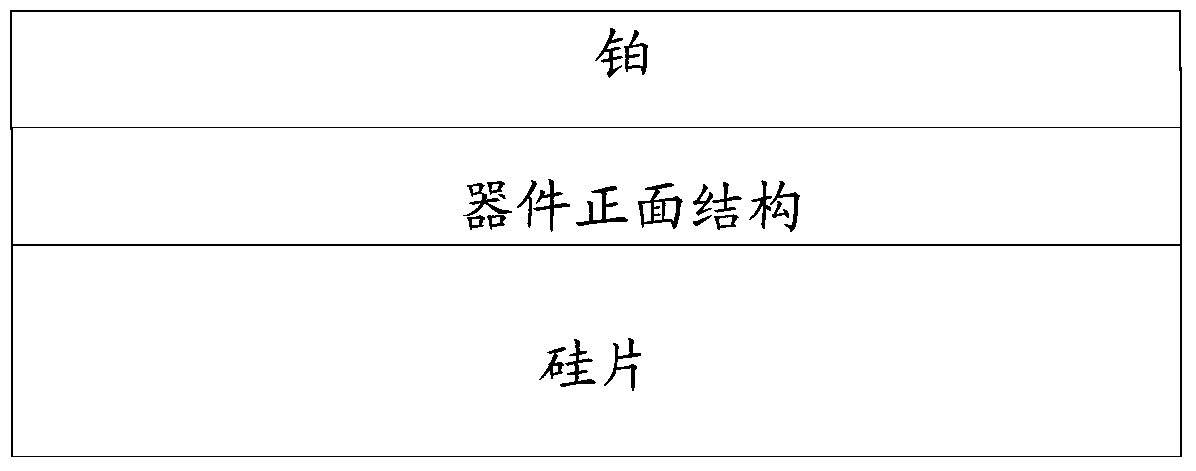

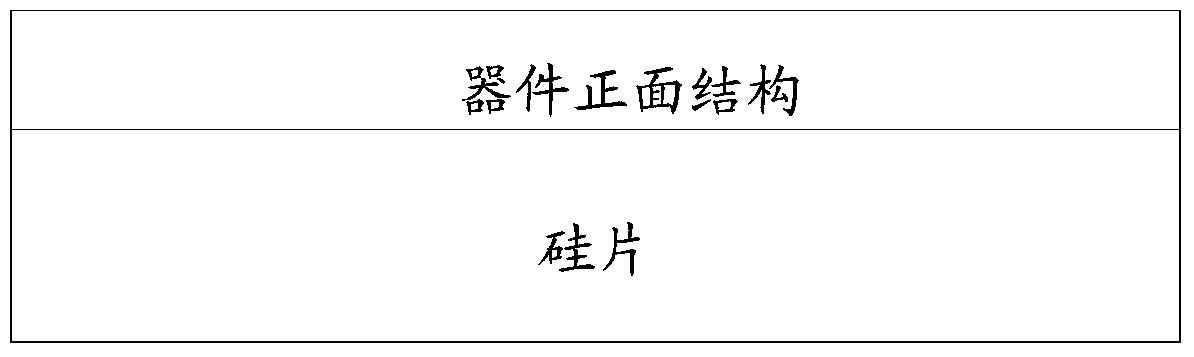

[0070] Such as Figure 8 As shown, firstly, a substrate is provided, which may be an N-type substrate, wherein the N-type substrate is formed by adding N-type impurities into silicon material. Then an N-type regional layer is formed on the surface of the substrate. The N-type regional layer is also manufactured by adding N-type impurities into the silicon material. And the thickness of the N-type region layer is far smaller than the thickness of the substrate, and the N-type region layer here is equivalent to the base region I in the fast recovery diode.

[0071] Step 202, forming a P-type region layer on the N-type region layer.

[0072] Such as Figure 9 As shown, after obtaining the ...

Embodiment 3

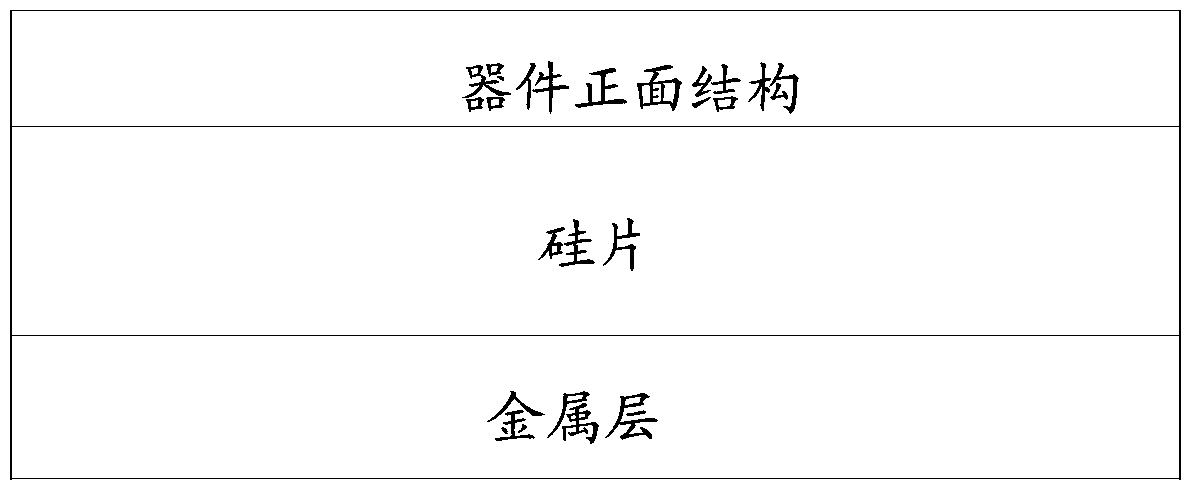

[0090] Embodiment 3 of the present invention provides a fast recovery diode, wherein the fast recovery diode is prepared by the above method. Moreover, the platinum concentration in the substrate region of the fast recovery diode formed in this embodiment is greatly reduced compared with the existing diodes, which can ensure that the platinum in the drift region formed by the N-type region generates defects and reduces the minority carrier recombination time. The platinum concentration in the substrate area is reduced, thereby reducing the reverse recovery time of the device and reducing the forward voltage drop of the device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com