A kind of preparation method of cathode carrier of lithium thionyl chloride battery

A lithium thionyl chloride battery and cathode technology, applied in the direction of electrode carrier/collector, battery electrode, positive electrode, etc., can solve the problems of increasing the conductivity of the cathode carrier, maintaining, and the cathode cannot meet high-current discharge or high-current pulse , to achieve the effect of convenient measurement process control, simple production process, and favorable mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

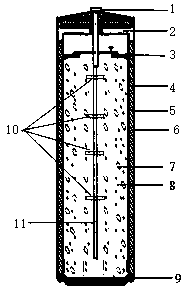

Image

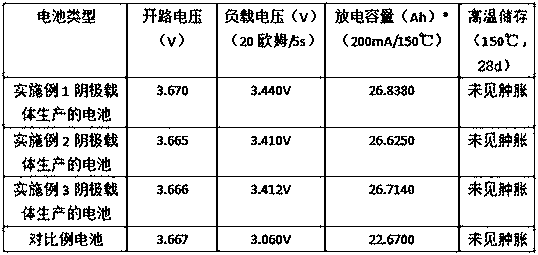

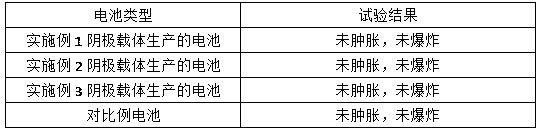

Examples

Embodiment 1

[0028] A preparation method for lithium thionyl chloride battery cathode carrier, comprising the steps of:

[0029] (1) Weighing and measuring: acetylene black, isopropanol, polytetrafluoroethylene emulsion with a concentration of 60%, anionic surfactant and deionized water in sequence according to the mass ratio of 71:2:4:2:20 Prepare materials;

[0030] (2) Preparation of paste: Add deionized water and isopropanol into the mixer barrel according to the measurement, and stir for 2 minutes; add anionic surfactant, and stir for 4 minutes; add acetylene black, and stir for 40 minutes; the concentration is 60 % polytetrafluoroethylene emulsion, stirred for 4 minutes to obtain paste;

[0031] (3) Dewatering and fibrosis: Take out the paste and transfer it to a stainless steel tray. The thickness of the paste is controlled at 5mm, and sent to the blast oven for dewatering and fibrosis. The temperature of the blast oven is controlled at 180°C and the time is controlled at 8 hours,...

Embodiment 2

[0036] A preparation method for lithium thionyl chloride battery cathode carrier, comprising the steps of:

[0037] (1) Weighing and measuring: Acetylene black, isopropanol, polytetrafluoroethylene emulsion with a concentration of 60%, anionic surfactant and deionized water are sequentially mixed according to the mass ratio of 76:5:6:4:20 Prepare materials;

[0038] (2) Preparation of paste: Add deionized water and isopropanol into the mixer barrel according to the measurement, and stir for 4 minutes; add anionic surfactant, and stir for 4 minutes; add acetylene black, and stir for 60 minutes; the concentration is 60 % polytetrafluoroethylene emulsion, stirred for 6 minutes to obtain paste;

[0039] (3) Dewatering and fibrosis: Take out the paste and transfer it to a stainless steel tray. The thickness of the paste is controlled at 80mm, and it is sent to the blast oven for dewatering and fibrosis. The temperature of the blast oven is controlled at 240°C and the time is contr...

Embodiment 3

[0044] A preparation method for lithium thionyl chloride battery cathode carrier, comprising the steps of:

[0045] (1) Weighing and measuring: Acetylene black, isopropanol, polytetrafluoroethylene emulsion with a concentration of 60%, anionic surfactant and deionized water are sequentially mixed according to the mass ratio of 73:4:5:6:20 Prepare materials;

[0046] (2) Preparation of paste: Add deionized water and isopropanol into the mixer barrel according to the measurement, and stir for 6 minutes; add anionic surfactant, and stir for 4 minutes; add acetylene black, and stir for 50 minutes; the concentration is 60 % polytetrafluoroethylene emulsion, stirred for 5 minutes to obtain paste;

[0047] (3) Dewatering and fibrosis: Take out the paste and transfer it to a stainless steel tray. The thickness of the paste is controlled at 65mm, and it is sent to the blast oven for dewatering and fibrosis. The temperature of the blast oven is controlled at 200°C and the time is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com