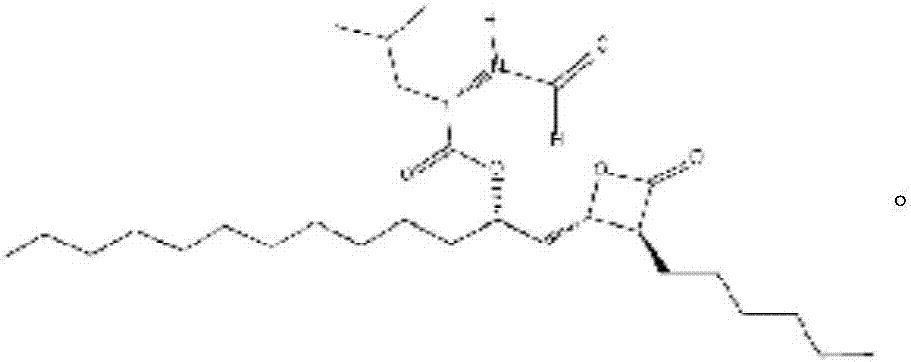

Weight losing tablet containing orlistat

A technology of orlistat and slimming tablets, which is applied in the field of medicine, can solve problems such as poor fluidity, low dissolution rate, slow progress, etc., and achieve the effect of avoiding thermal decomposition, avoiding damp heat decomposition, and improving dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

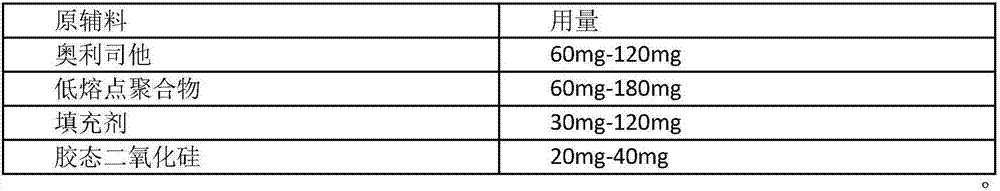

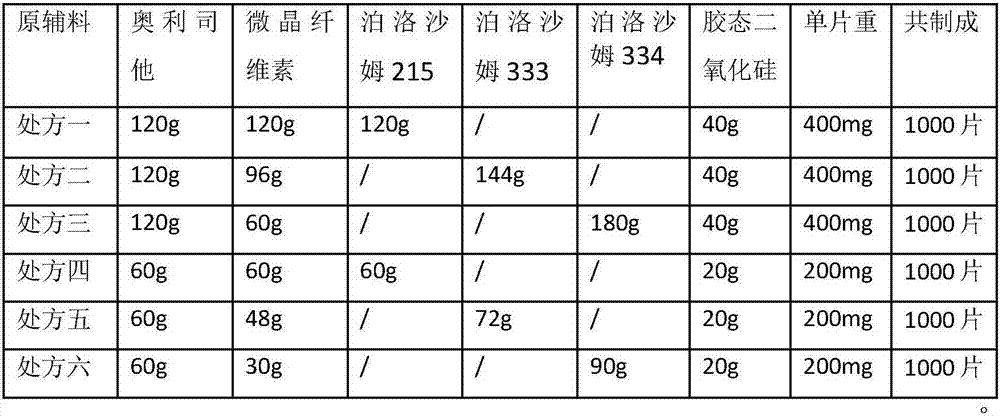

[0074] Example 1 Preparation of 60 mg specification orlistat tablet (unit: g)

[0075]

[0076] Preparation Process:

[0077] Step 1. Take orlistat and microcrystalline cellulose, pulverize them, pass through a 100-mesh sieve, and set aside;

[0078] Step 2. Take the prescribed amount of orlistat, microcrystalline cellulose, polymer, and colloidal silicon dioxide, put them in a turbulent flow mixer, and mix for about 4 minutes;

[0079] Step 3: Continuously feed the mixed material at a certain rate, and continuously extrude the twin-screw extruder through an orifice with a certain aperture at a melt temperature of 45° C. to obtain a strip-shaped semi-solid intermediate;

[0080] Step 4, cutting the strip intermediate obtained in step 3 according to a certain thickness to obtain orlistat tablets;

[0081] Step 5: Packing the orlistat tablet obtained in step 4 with PVDC / aluminum foil having high moisture-proof performance as the packaging material to obtain a finished produ...

Embodiment 2

[0082] Example 2 Preparation of 120mg Orlistat Tablets (Unit: g)

[0083]

[0084]

[0085] Preparation Process:

[0086] Step 1. Take orlistat and microcrystalline cellulose, pulverize them, pass through a 100-mesh sieve, and set aside;

[0087] Step 2. Take the prescribed amount of orlistat, microcrystalline cellulose, polymer, and colloidal silicon dioxide, put them in a turbulent flow mixer, and mix for about 4 minutes;

[0088] Step 3: Continuously feed the mixed material at a certain rate, and continuously extrude the twin-screw extruder through an orifice with a certain aperture at a melt temperature of 45° C. to obtain a strip-shaped semi-solid intermediate;

[0089] Step 4, cutting the strip intermediate obtained in step 3 according to a certain thickness to obtain orlistat tablets;

[0090] Step 5: Packing the orlistat tablet obtained in step 4 with PVDC / aluminum foil having high moisture-proof performance as the packaging material to obtain a finished produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com