Remediation method for petroleum-contaminated soil

A remediation method and technology for polluted soil, applied in the field of remediation of petroleum-contaminated soil, can solve problems such as difficult control, ecosystem destruction, consumption, etc., to improve roughness and specific surface area, promote full contact and reaction, and high catalytic degradation. efficacy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

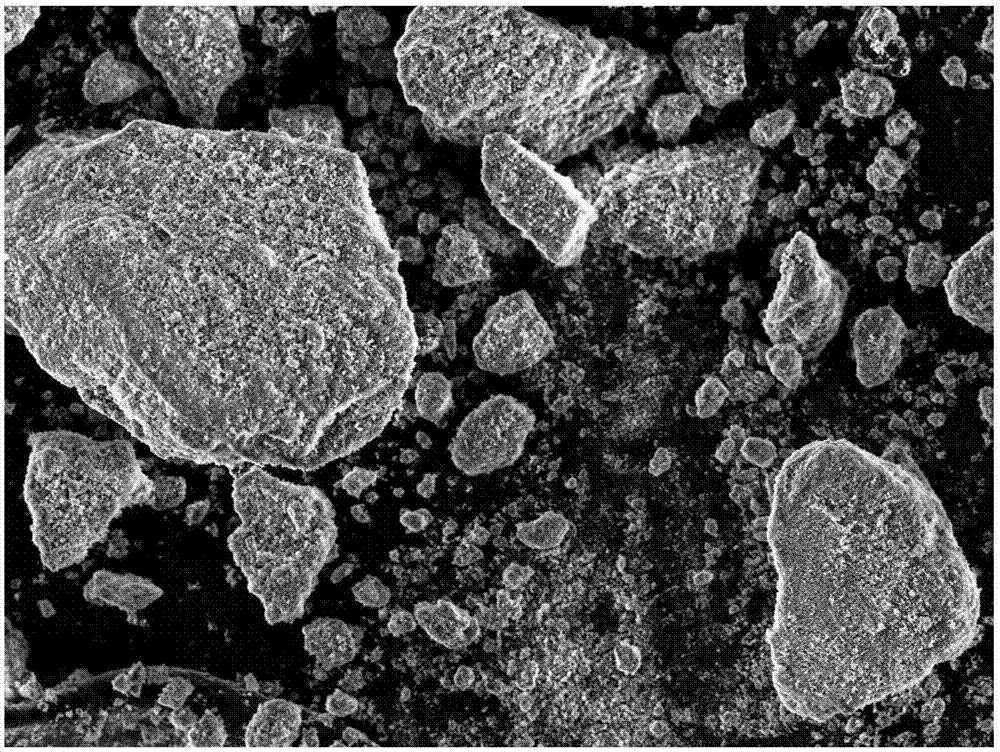

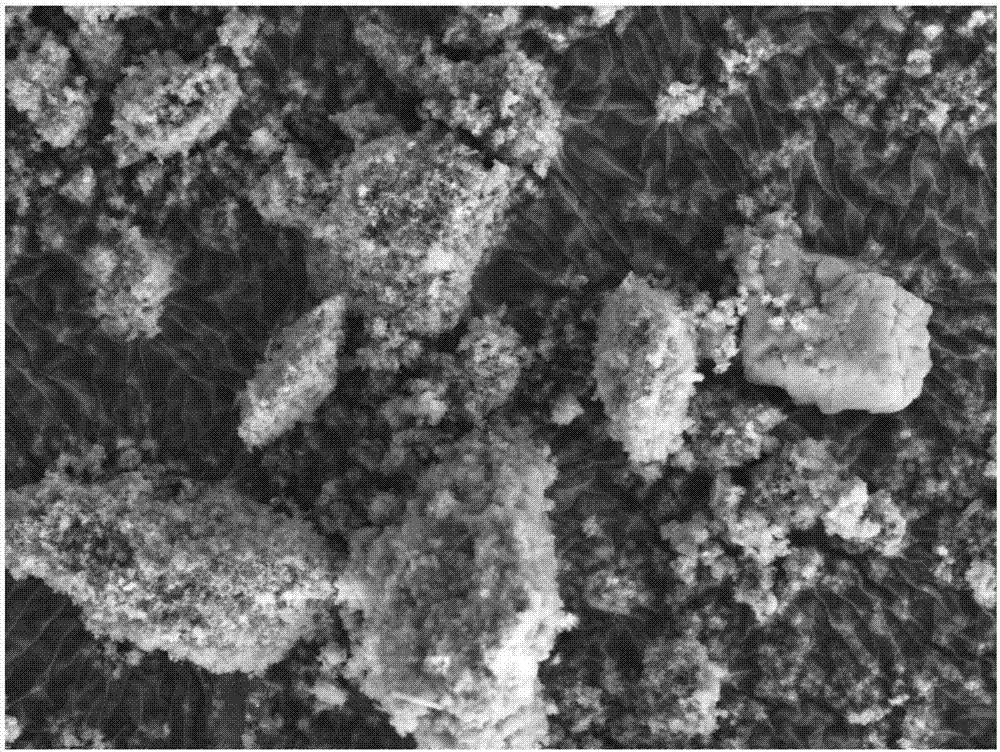

Image

Examples

Embodiment 1

[0036] A method for remediating petroleum-contaminated soil, comprising the steps of:

[0037] 1) Add 30g of zeolite (iron ion carrier) and 20g of ferrous sulfate (iron-donating substance) into a 500mL catalyst preparation container, add 200mL of distilled water into the catalyst preparation container, adjust the pH value of the resulting mixture to 5, and then Heated in a water bath and evaporated to dryness, then rinsed with distilled water until neutral, and dried in an oven at 105°C for 4 hours to obtain a Fenton-like catalyst;

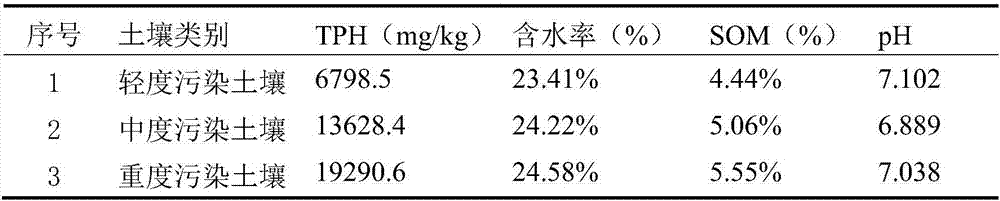

[0038] 2) First measure the content of petroleum in the petroleum-contaminated soil to be repaired (oil-based drilling cuttings-contaminated soil, light petroleum-contaminated soil), see Table 1, select the proportion of contaminated soil, Fenton-like catalyst and hydrogen peroxide as 1g: 0.2g:0.75mL, add a Fenton-like catalyst and hydrogen peroxide to form a mixture A in the petroleum-contaminated soil to be repaired, and adjust the pH of the rea...

Embodiment 2

[0043] A method for remediating petroleum-contaminated soil, the specific steps of which are roughly the same as those in Implementation 1, the difference being that the petroleum-contaminated soil to be repaired is moderate petroleum-contaminated soil (see Table 1), and the resulting remediated soil The removal rate of petroleum is 65.25%.

Embodiment 3

[0045] A method for remediating petroleum-contaminated soil, the specific steps of which are roughly the same as in Implementation 1, the difference being that the petroleum-contaminated soil to be repaired is heavily petroleum-contaminated soil (see Table 1), and the petroleum-contaminated soil in the obtained remediation The class removal rate is 52.31%.

[0046] Physicochemical properties of remediation petroleum contaminated soil samples in Table 1 Examples 1-3

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com