Periodic oscillation laser welding method and welding assembly

A technology of laser welding and periodic oscillation, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of uneconomical, low utilization rate of galvanometer, low moving speed and response speed of worktable, etc., to achieve easy welding , High efficiency and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

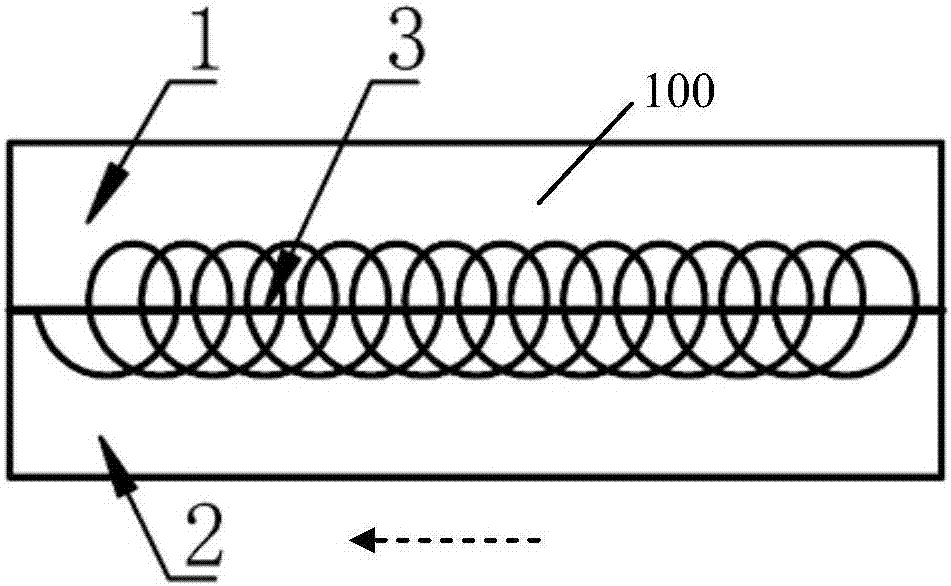

[0043] Figure 1-8b It shows a flow chart of the steps of the periodic oscillating laser welding method of the present invention and a schematic diagram of welding, which includes the following steps:

[0044] S1. Place workpieces 1 and 2 to be welded (such as 6061 alloy, etc.) on the workbench 100 to form a weld 3 to be welded;

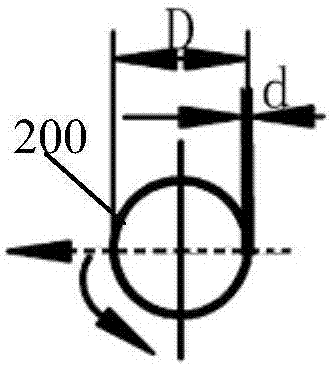

[0045] S2. Generate a welding laser (the welding laser can be generated by swinging a laser welding head, etc.), and make the welding laser oscillate according to a preset pattern 200 and a preset frequency (according to Figure 2b , 3b, 4b, 5b, 6b and 7b in the direction indicated by the solid arrow to complete the preset graphics), at the same time, the workbench is along the main direction of the weld track to be welded (ie Figures 2a-8b In the direction indicated by the dotted arrow in the center), the welding seam to be welded is welded by the welding laser.

[0046] Further, in the step S2, the preset graphics include regular or irregular gr...

Embodiment 2

[0053] The present invention also provides a welding assembly for realizing the above-mentioned welding method, which includes:

[0054] Workbench, which is used to carry workpieces to be welded;

[0055] An oscillating laser welding head, which is used to generate a welding laser, and make the welding laser oscillate according to a preset pattern and a preset frequency;

[0056] And a moving component, which is used to move the worktable along the main direction of the welding seam trajectory.

[0057] Preferably, the welding assembly also includes:

[0058] The control device has a control program, which is used to control the movement of the oscillating laser welding head along the track of the welding seam to be welded, so as to compensate the deviation of the welding seam in the curve or broken line welding seam in positive and negative directions.

[0059] As shown in Figures 9-12, in the welding method and welding assembly of the present invention, the laser spot emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com