Bionic anti-erosion surface with composite coating adhesive

A composite coating and anti-erosion technology, applied in the direction of layered products, metal layered products, rubber layered products, etc., can solve the problems of anti-erosion wear, erosion, etc., and achieve low cost, simple use method, The effect of good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

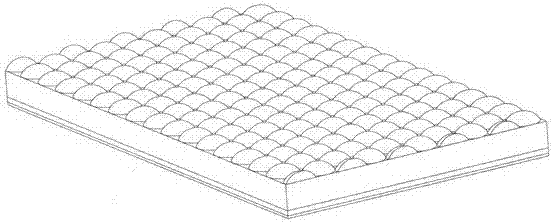

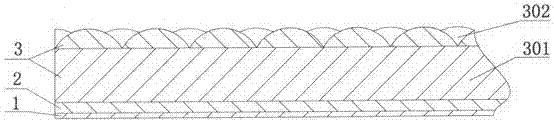

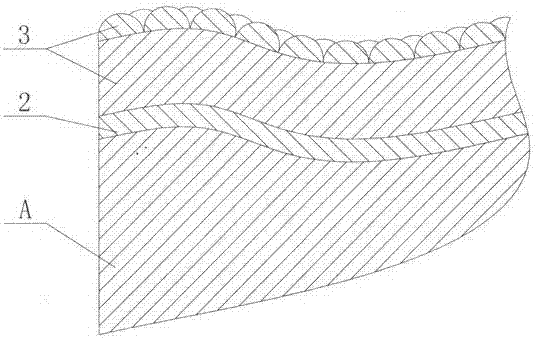

[0020] see figure 1 and figure 2 As shown, this embodiment includes a three-layer structure, which is an isolation protection layer 1 , an adhesive layer 2 and a biomimetic functional layer 3 from the surface of the substrate to the outside.

[0021] The isolation protection layer 1 is a thin release paper layer or a thin silicone oil paper layer covering the surface of the bonding layer, which is waterproof and dustproof, and can effectively protect the integrity of the bonding layer during transportation and storage. Adhesive peeling off. The thin release paper layer is a glassine release paper layer.

[0022] The adhesive layer 2 is a layer of hot-melt adhesive film between the isolation protection layer 1 and the bionic functional layer 3 , and is glued to the bionic functional layer 3 . The adhesive layer 2 connects the biomimetic functional layer 3 and the surface of the mechanical parts to be treated, and the hot melt adhesive film bonds quickly, and is widely used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com