A kind of anti-corrosion multi-component coating for high shielding parts, its preparation method and the device used in the preparation method

An anti-corrosion and multi-dimensional technology, applied in the coating, superimposed layer plating, metal material coating process, etc., can solve the problem of increasing the toughness and corrosion resistance of the blade surface coating, poor relative compactness of the film, and the brittleness of the coating. Increase and other problems, to achieve the effect of high density, good uniformity, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a high-shielding anti-corrosion multi-layer coating, comprising the following steps:

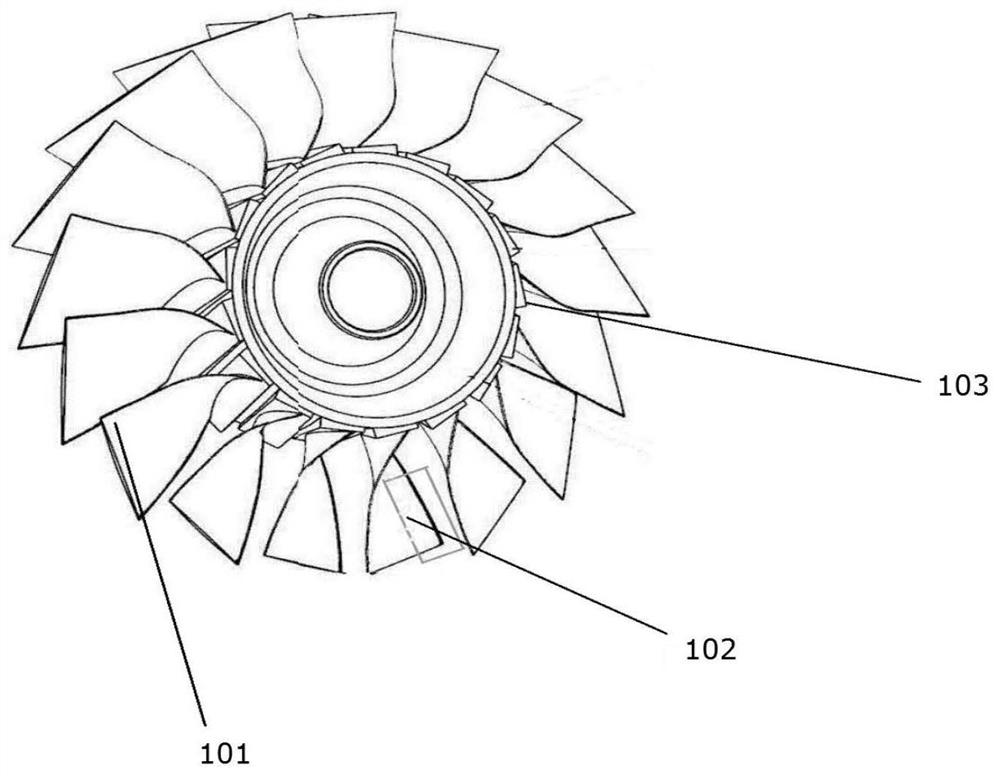

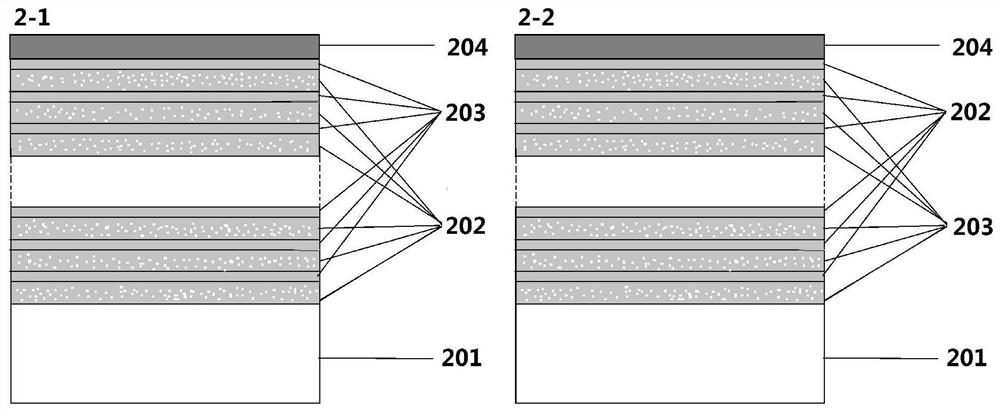

[0030] Using carbon-silicon target and carbon-silicon-titanium target as cathode, using magnetic filter deposition method, multi-arc deposition method and the first high-power pulsed magnetron method to alternately deposit TiSiN film layer and TiSiCN film layer on the substrate of high-shielding parts to obtain TiSiN / TiSiCN composite alternating layers;

[0031] Depositing Al on the surface of the TiSiN / TiSiCN composite alternating layer by using the second high-power pulsed magnetron method 2 o 3 The film layer is used to obtain a high-shielding anti-corrosion multi-layer coating.

[0032] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0033] In the present invention, the carbon-silicon target and the carbon-silicon-titaniu...

Embodiment 1

[0069] S1: The surface of the substrate is cleaned with an Ar ion source, the energy of the ion source for the anode layer is 250eV, and the beam intensity is 4A to obtain a substrate with a high shielding element.

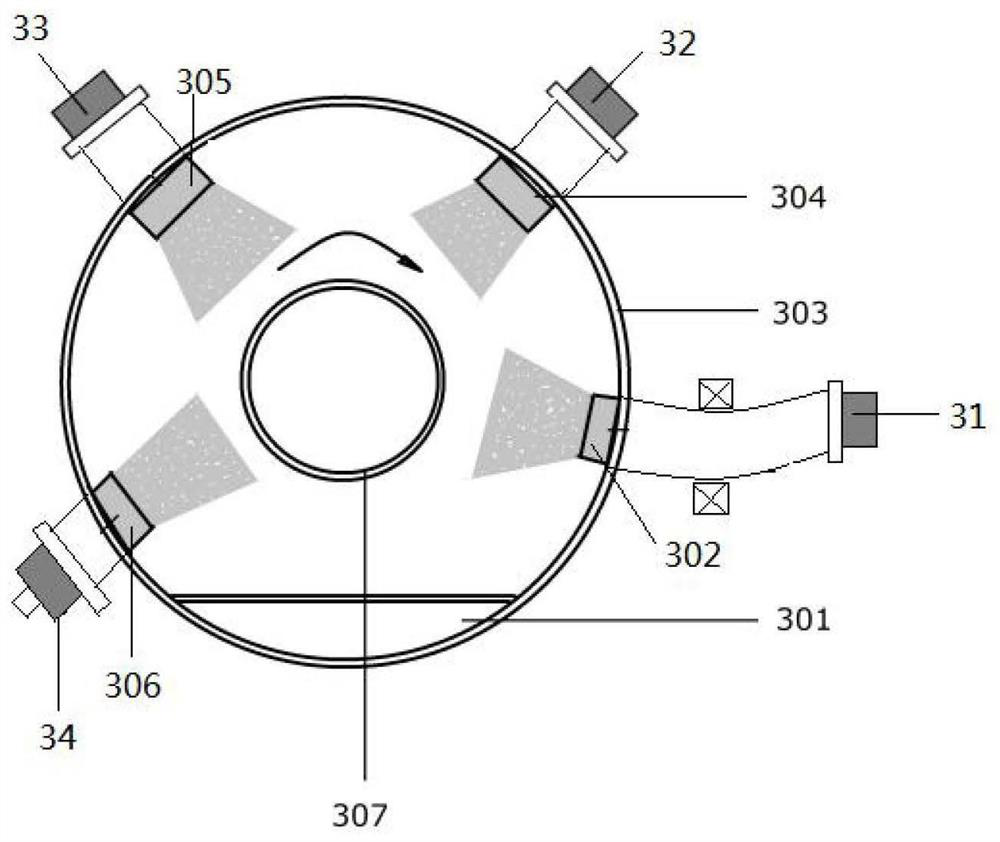

[0070] S2: Fix the high shielding part to the fixture tooling 307 by bolts and rotate at a speed of 2r / min. When the revolution reaches the multi-arc deposition port 306, the multi-arc deposition device deposits a TiSiN film layer on the surface of the high shielding part substrate, and revolves to the magnetic filter At the deposition port 302, the magnetic filter device deposits a dense TiSiN film layer on the surface of the TiSiN film layer, and when it revolves to the first high-power pulse magnetron deposition port 304, the first high-power pulse magnetron deposition device deposits TiSiCN on the surface of the TiSiN film layer. film layer; repeating the above deposition steps to obtain TiSiN / TiSiCN composite alternating layers;

[0071] Among them, the thick...

Embodiment 2

[0082] S1: The surface of the substrate is cleaned with an Ar ion source, the energy of the ion source for the anode layer is 250eV, and the beam intensity is 4A to obtain a substrate with a high shielding element.

[0083] S2: Fix the high shielding part to the fixture tooling 307 by bolts and rotate at a speed of 3r / min. When the revolution reaches the multi-arc deposition port 306, the multi-arc deposition device deposits a TiSiN film layer on the surface of the high shielding part substrate, and revolves to the magnetic filter At the deposition port 302, the magnetic filter device deposits a dense TiSiN film layer on the surface of the TiSiN film layer, and when it revolves to the first high-power pulse magnetron deposition port 304, the first high-power pulse magnetron deposition device deposits TiSiCN on the surface of the TiSiN film layer. film layer; repeating the above deposition steps to obtain TiSiN / TiSiCN composite alternating layers;

[0084] Among them, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com