Preparation method of iron-based oxide aerogel

A technology of iron-based oxides and aerogels, applied in the direction of ferrous oxides, iron compounds, chemical instruments and methods, etc., can solve the problems of complex operation, high energy consumption, and long preparation cycle, and achieve high purity , large specific surface area, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

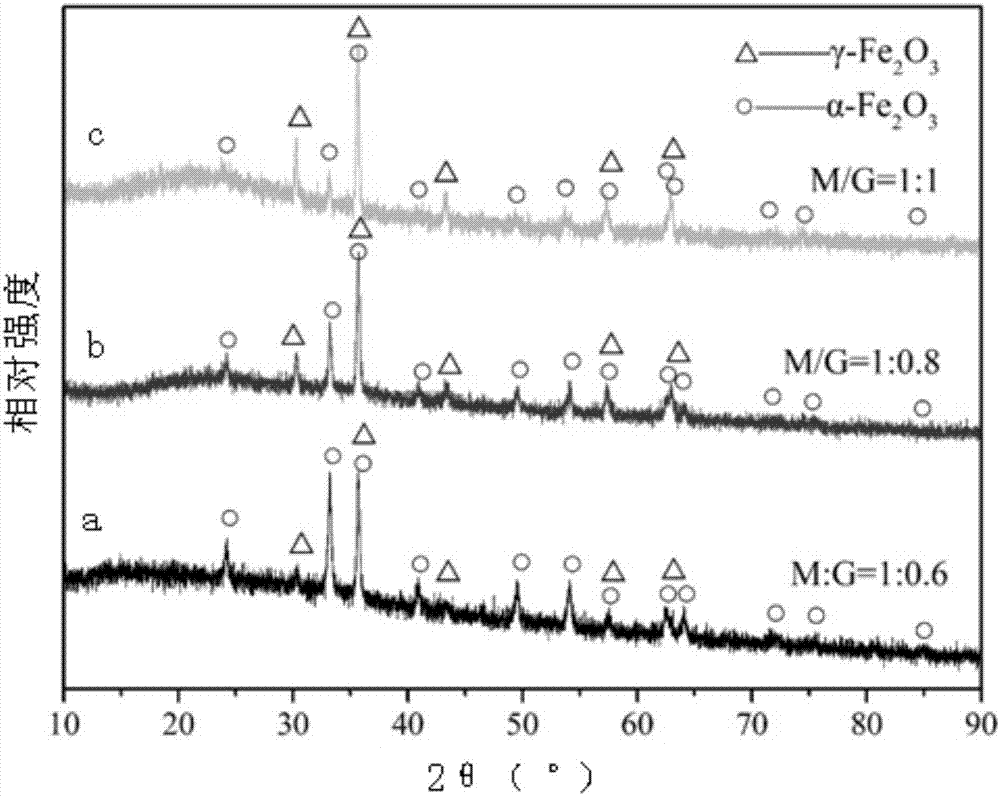

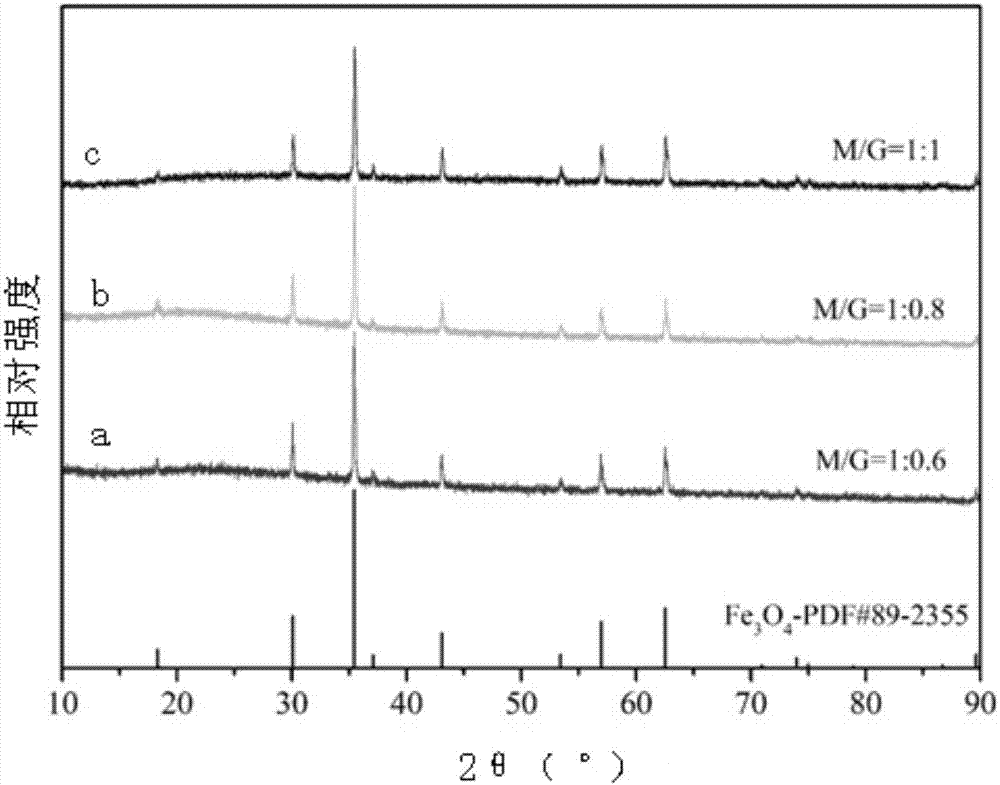

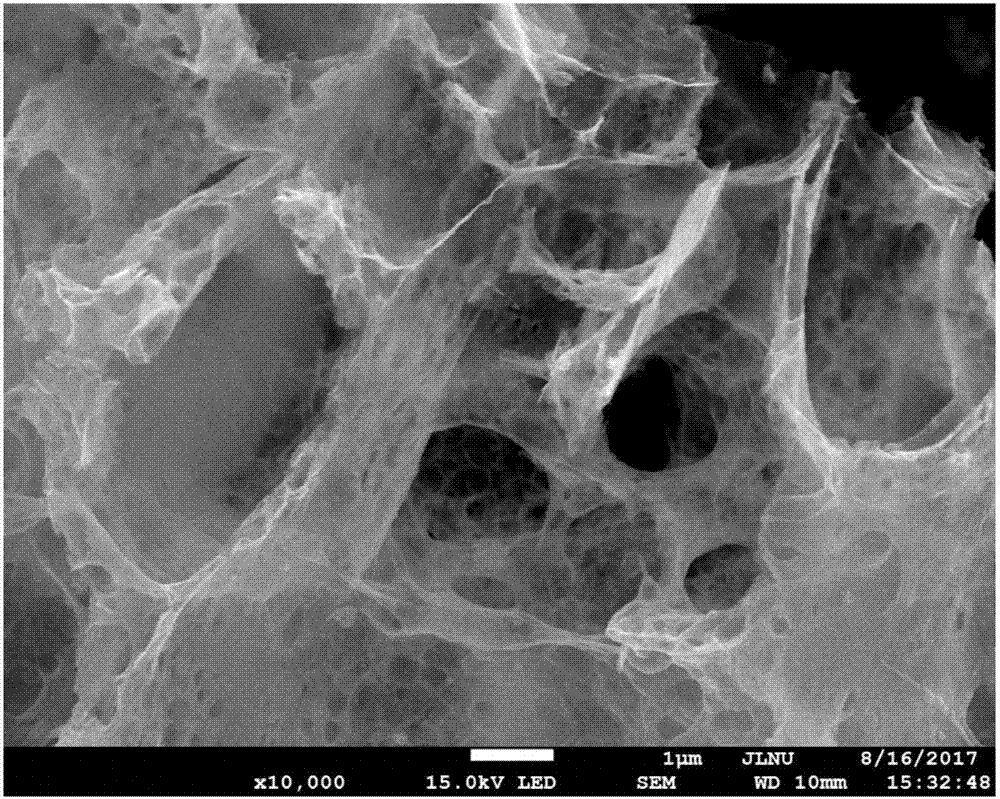

[0023] Specific embodiment one: the preparation method of the iron-based oxide aerogel of the present embodiment is carried out according to the following steps:

[0024] 1. Weigh various metal element nitrates according to the stoichiometric ratio of various metal elements in the iron-based oxide, and then weigh the pore-forming reactant, wherein the pore-forming reactant is glycine (NH 2 CH 2 COOH) or citric acid, the molar ratio (M / G) of all metal element nitrates to pore-forming reagents is 1: (0.5-1.5); add all metal element nitrates and pore-forming reagents to an appropriate amount of deionized water , magnetic stirring to make it dissolve, and obtain the precursor solution;

[0025] 2. Under stirring conditions, heat the precursor solution to a temperature of 180°C to 220°C and keep it until the water is completely evaporated, and a self-propagating combustion reaction occurs to obtain the iron-based oxide aerogel.

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the iron-based oxide is Fe 2 o 3 、CoFe 2 o 4 、NiFe 2 o 4 , MnFe 2 o 4 、BaFe 12 o 19 or Mn x Zn 1-x Fe 2 o 4 (x=0-1); other is the same as the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the molar ratio (M / G) of all metal element nitrates and pore-forming reagents in step one is 1:0.6; others are the same as specific embodiment one or two the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com