Assembly MBR (membrane bioreactor) container type integrated equipment for treating sewage in villages and small towns

A sewage treatment, container-type technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, biological treatment equipment, etc., can solve the problems of long hydraulic retention time, long production cycle, low manufacturing level, etc., to achieve The effect of short hydraulic retention time, small equipment footprint and low equipment manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

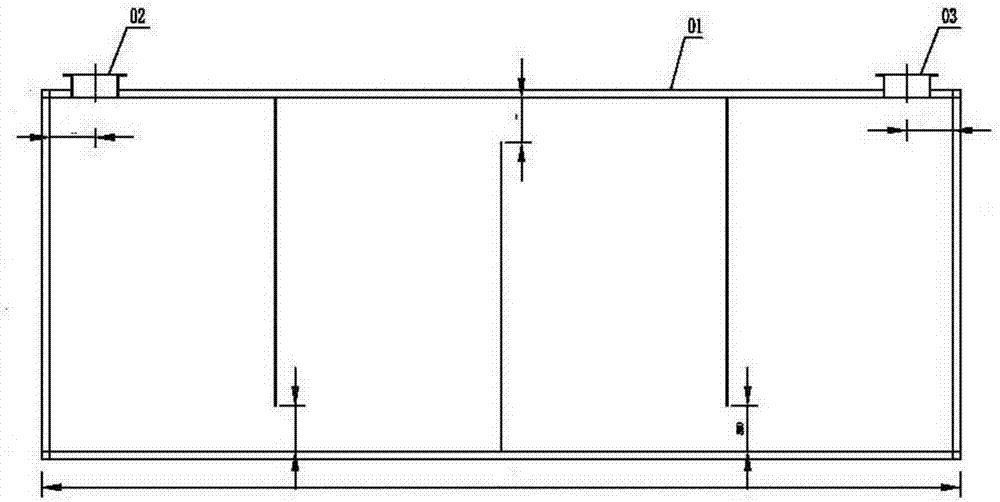

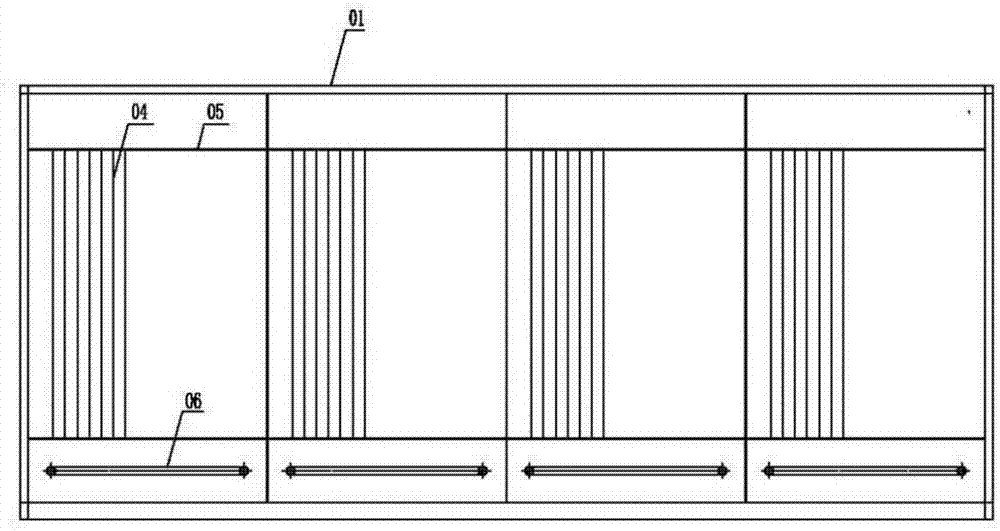

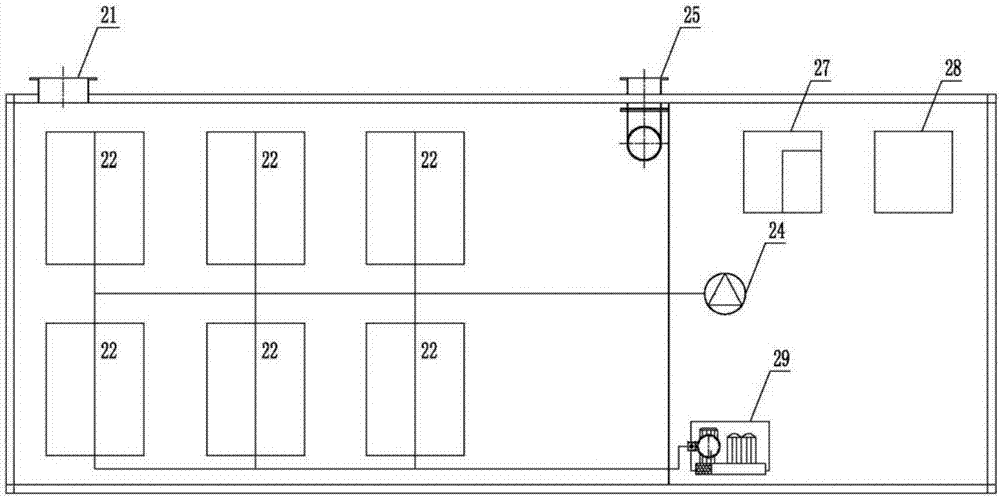

[0040] An assembled MBR container-type integrated equipment for sewage treatment in villages and towns, such as Figure 1-5As shown, it mainly includes SND biochemical box and MBR membrane box, wherein: said SND biochemical box adopts SND synchronous nitrification and denitrification process, which can simultaneously remove ammonia nitrogen and total nitrogen while removing organic matter. The SND biochemical box mainly includes box 01 (standard 20-inch container structure, size 6.058m (length) x 2.438m (width) x 2.700m (height), water inlet a02, water outlet 03, biological filler 04, filler Frame 05, aeration system a06, etc., the water inlet a02 and water outlet 03 are set at the lower part of the tank, and the aeration system 06 is installed under the filler frame 05. The main design parameters of the SND biochemical box: processing capacity 100-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com