Fine iron tailing CA mortar used for rapidly repairing pavement at room temperature and preparation method thereof

A technology of fine iron and tailings, applied in the field of surface repair materials, to promote the sustainable development of resources, reduce environmental pollution and ecological damage, and alleviate the effect of large-scale stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

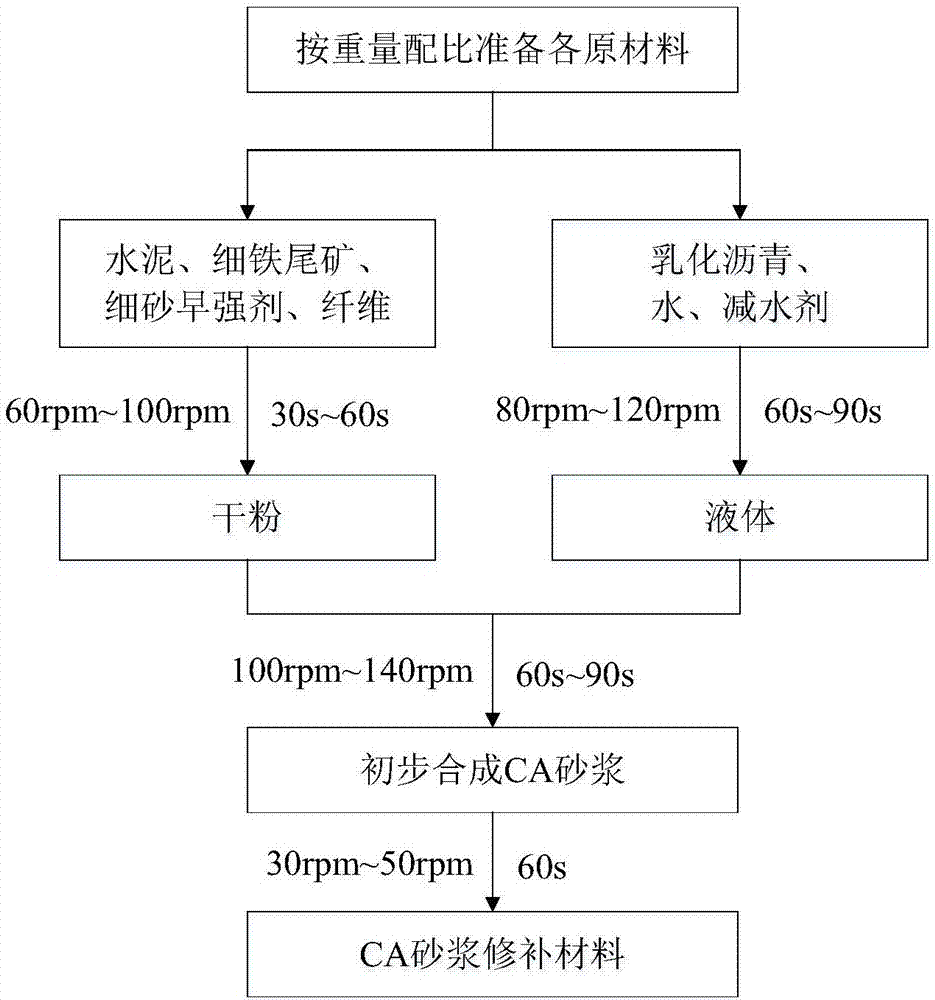

[0040] The present invention also provides a method for preparing fine iron tailings CA mortar used for rapid repair of road surface at normal temperature, comprising the following steps:

[0041] According to the actual mixing amount, prepare each raw material according to the weight ratio;

[0042] Preparation of dry material: Dry mix cement, fine iron tailings, fine sand, early strength agent and fiber in a mixer for 30s to 60s according to the above ratio, and the stirring speed is 60rpm to 100rpm to obtain a uniformly mixed dry material;

[0043] Preparation of CA mortar: Mix the emulsified asphalt, water and water reducer in the mixer for 60s~90s according to the proportions, and the stirring speed is 80rpm~120rpm; after stirring evenly, add the dry powder prepared in step 1 and continue stirring for 60s~90s, and then stir The speed is 100rpm~140rpm;

[0044] Reduce the stirring speed to 30rpm-50rpm, and then stir for 60s to obtain the target CA mortar;

[0045] The to...

Embodiment 1

[0048] A kind of fine iron tailings CA mortar used for fast repairing of asphalt pavement at room temperature and its preparation method, according to the actual mixing amount, firstly weigh 30 parts of cement, 160 parts of fine iron tailings, 130 parts of fine sand, inorganic matter 0.8 parts of strong agent calcium chloride and 0.2 parts of lignin fiber were stirred in a mixer at a speed of 60rpm for 60s to obtain a dry powder; then 100 parts of emulsified asphalt, 0.15 parts of polycarboxylate superplasticizer and 6 parts of water were mixed in a mixer at a speed of 100rpm Stir at the speed of 90s; after stirring evenly, put the dry powder into it and continue stirring at the speed of 120rpm for 60s, and finally reduce the stirring speed to 30rpm and stir for 60s to obtain the target CA mortar.

Embodiment 2

[0050] A kind of fine iron tailings CA mortar and its preparation method for normal temperature rapid repair of asphalt pavement, according to the actual mixing amount, first weigh 40 parts of cement, 180 parts of fine iron tailings, 120 parts of fine sand and lignin fiber 0.3 parts were stirred in a mixer at a speed of 80rpm for 40s to obtain dry powder; then 80 parts of emulsified asphalt, 1.0 parts of organic early strength agent triethanolamine, 0.2 parts of polycarboxylate superplasticizer and 5 parts of water were mixed in a mixer at a speed of 90rpm Stir for 80s; after stirring evenly, put the dry powder into it and continue stirring for 90s at a speed of 100rpm, and finally reduce the stirring speed to 40rpm and stir for 60s to obtain the target CA mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com