Air purification coating additive and preparation method and application thereof

A technology for purifying air and additives, applied in chemical instruments and methods, separation methods, coatings, etc., can solve problems such as low efficiency and low catalytic efficiency, and achieve the effects of convenient trial, high electron mobility, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

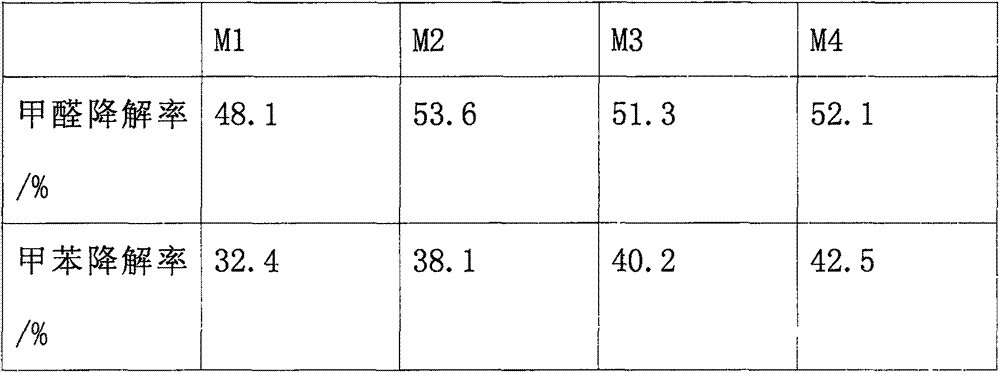

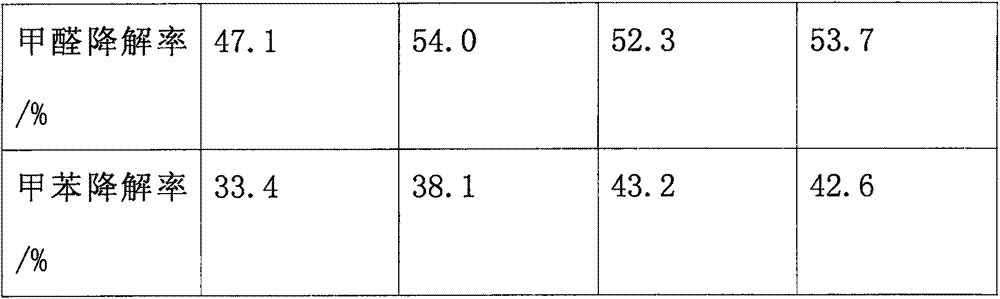

Embodiment 1

[0027] Add 5 parts of 1% graphene oxide aqueous solution to 50 parts of water, stir evenly, slowly add 4 parts of butyl titanate dropwise, continue stirring at 30°C for 2-3 hours after the dropwise addition, then add 3 parts of template agent P123 to dissolve in 80 parts of aqueous solution, after mixing, add hydrochloric acid to a concentration of 1-2M, then dropwise add 8 parts of tetraethyl orthosilicate, react at 40°C for 15h after the dropwise addition, then raise the temperature to 95°C and age for 30h to obtain a black mixture . The black mixture was filtered and dried at 60° C. for 10 h to obtain a gray-black solid. The solid was burned at 500° C. for 5 h under the protection of an inert gas to remove the template to obtain the TiO2 immobilized graphene-modified mesoporous amphiphilic composite material M1.

Embodiment 2

[0029] Add 10 parts of 1% graphene oxide aqueous solution to 80 parts of water, stir evenly, slowly add 5 parts of isopropyl titanate dropwise, continue stirring at 40°C for 2 hours after the dropwise addition, then add dropwise 4 parts of template agent F127 to dissolve in 70 parts of aqueous solution, after mixing, add hydrochloric acid to a concentration of 1-2M, then dropwise add 9 parts of butyl orthosilicate, react at 40°C for 15h after the dropwise addition, then raise the temperature to 120°C and age for 20h to obtain a black mixture . The black mixture was filtered and dried at 100° C. for 5 h to obtain a gray-black solid. The solid was burned at 500° C. for 10 h under the protection of an inert gas to remove the template to obtain the TiO2 immobilized graphene-modified mesoporous amphiphilic composite material M2.

Embodiment 3

[0031] Add 15 parts of 1% graphene oxide aqueous solution to 50 parts, stir evenly, slowly add 5 parts of titanium tetrachloride dropwise, continue stirring at 40°C for 3 hours after the dropwise addition, then add dropwise 4 parts of template agent P123 to dissolve in 100 parts of aqueous solution, after mixing, add hydrochloric acid to a concentration of 1-2M, then dropwise add 8 parts of methyl orthosilicate, react at 40°C for 20h after the dropwise addition, then increase the temperature to 80°C and age for 48h to obtain a black mixture . The black mixture was filtered and dried at 80° C. for 6 h to obtain a gray-black solid. The solid was burned at 500°C for 6 hours under the protection of an inert gas to remove the template to obtain the TiO2 immobilized graphene-modified mesoporous amphiphilic composite material M3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com