A self-cleaning fracturing proppant and its application

A clean fracturing and proppant technology, applied in wellbore/well parts, production fluid, earthwork drilling and production, etc., can solve the problems of reduced conductivity and easy blockage of fractures, and achieve increased fracture conductivity and enhanced Fracture conductivity, the effect of improving fracture conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

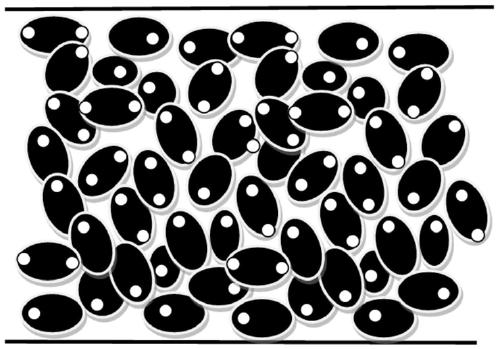

[0030] A self-cleaning fracturing proppant, comprising a proppant particle framework, the proppant particle framework is ellipsoidal, and a cylindrical channel passing through the ellipsoid is arranged on the major axis of the ellipsoid, and the cylindrical The acid etching solution is filled in the cylindrical channel, and the two ends of the cylindrical channel are sealed by a degradable polymer.

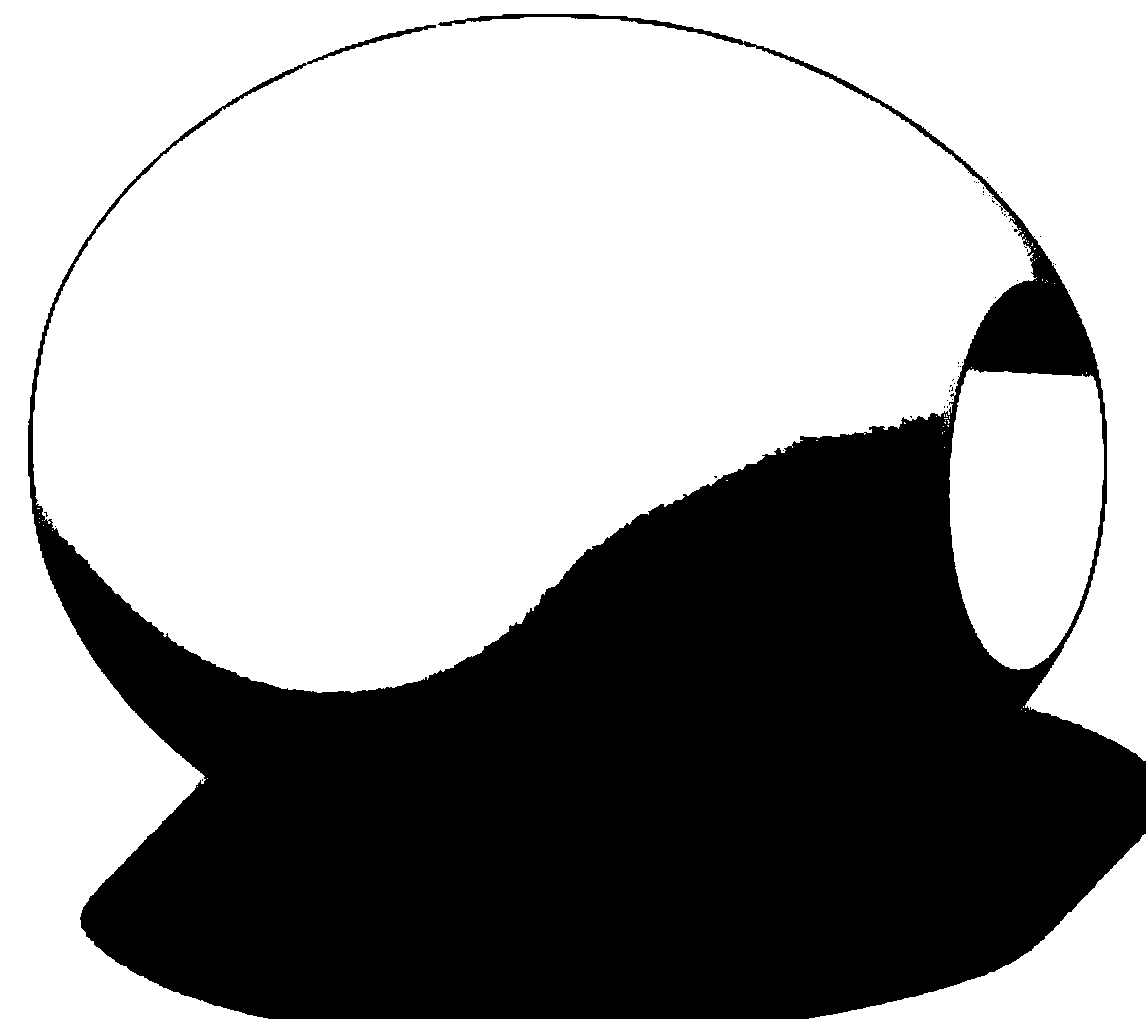

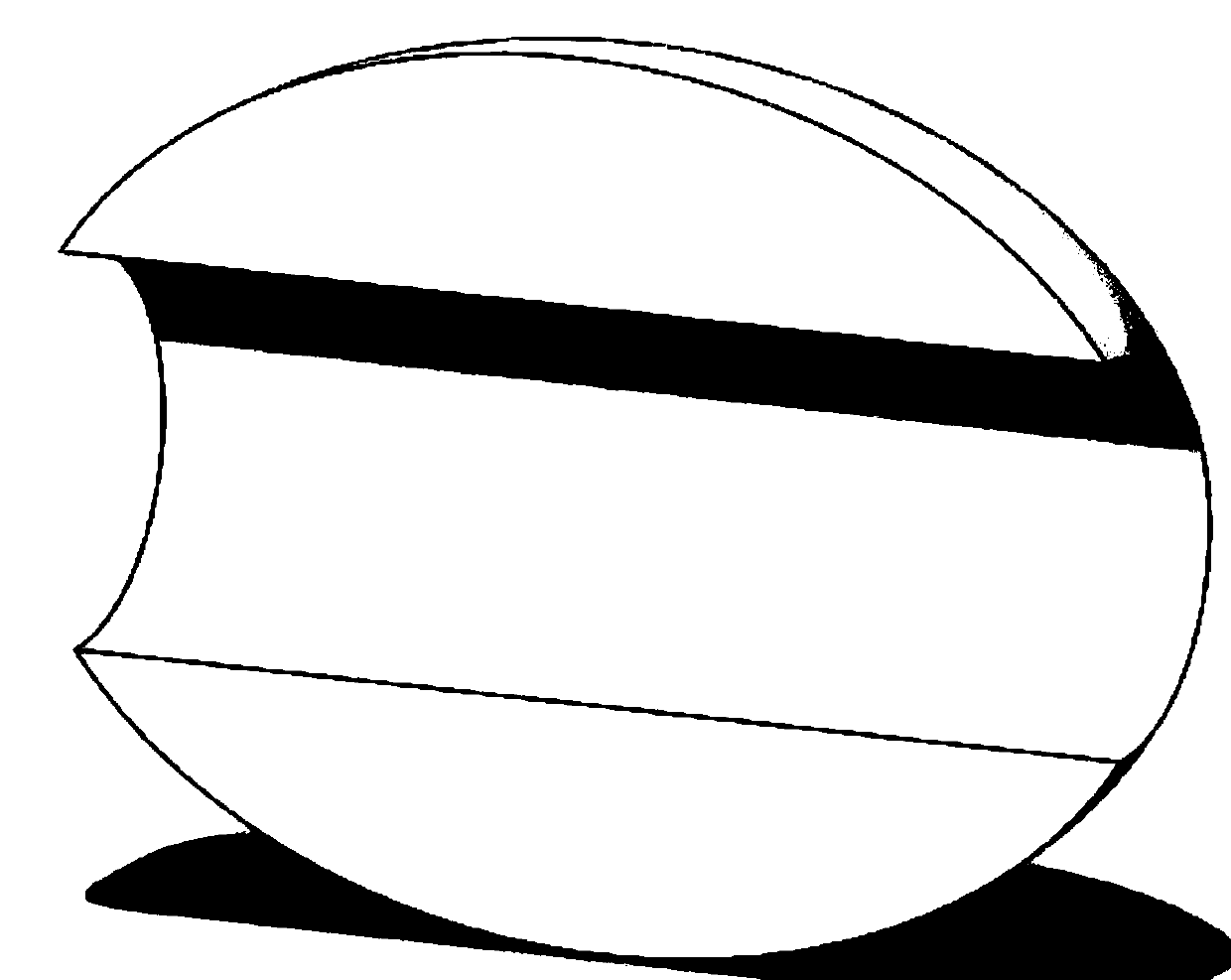

[0031] The cylindrical passage is established in the following manner: a hole is opened along the long axis of the ellipsoid, and the cylinder radius of the cylindrical passage is one-fifth to one-third of the length of the short axis of the ellipsoid. The schematic diagram of the appearance of the proppant particle framework is shown in figure 1 shown, from figure 1 It can be seen that there is one channel drilled in the proppant particle frame, along the long axis of the ellipsoid, the structure is stable and the force is uniform.

[0032] The total volume of the proppant is d...

Embodiment 9

[0037] The application of the proppant described in embodiment 1-8 comprises steps as follows:

[0038] (1) At the beginning of fracturing, the pre-fluid is pumped into the formation to form cracks of a certain width and length in the formation;

[0039] (2) The sand-carrying liquid mixed with the proppant described in Examples 1-8 was mixed with 3-10m 3 / min displacement is pumped into the formation to support the fracture geometry that has formed.

[0040] In step (2), the volume fraction of the proppant in the total volume of the sand-carrying liquid is the sand ratio, and the sand ratio is 80%.

[0041] After the crack is closed, the sealed degradable polymer material degrades, and the acid etching liquid contained inside flows out, and dissolves the impurities and debris that block the crack, and causes uneven etching on the crack wall, enlarging the crack diversion capacity. The proppant with holes inside and the voids etched by the acid etching solution form a new fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com