Gold nano-rod and up-conversion nano-crystal composite nano-material as well as preparation method thereof

A technology of nanocrystalline composite and gold nanorods, which is applied in nanotechnology, nanotechnology, nano-optics, etc., can solve the problems of insufficient mechanism analysis and theoretical explanation, and achieve the effect of improving luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

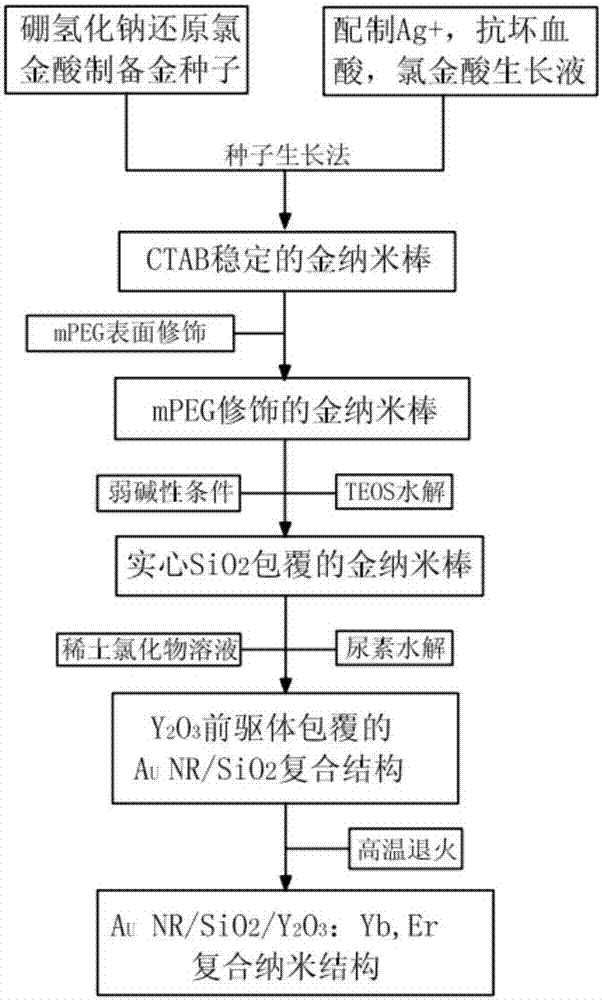

Method used

Image

Examples

Embodiment 1

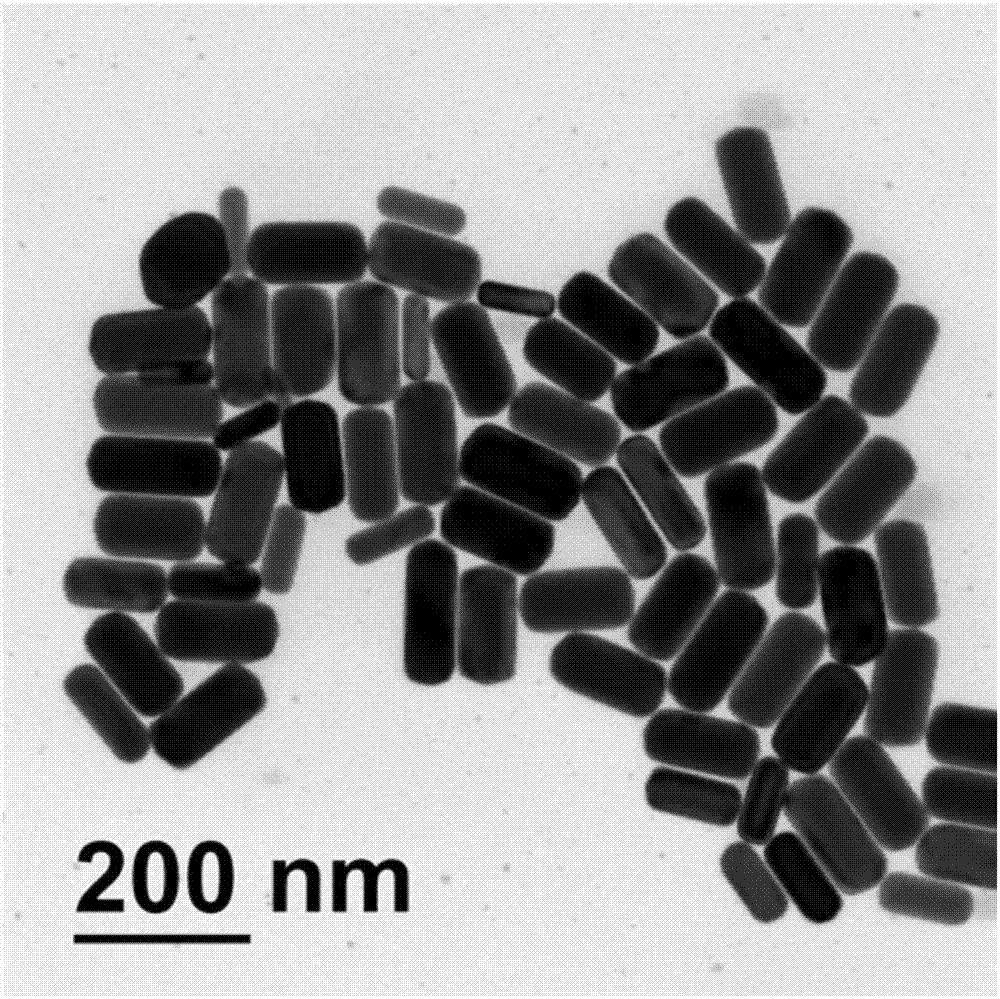

[0055] 1) Preparation of gold nanorods:

[0056] First prepare the gold seed solution, add 5mL 0.5mM HAuCl in the glass bottle 4 solution and 5mL 0.2M CTAB (cetyltrimethylammonium bromide) solution, and stirred at a uniform speed. Then take 1mL and freshly prepare 0.01M NaBH with ice water 4 solution, added to CTAB-Au 3+ into the mixed solution and stirred rapidly for 2 minutes. The prepared gold seed solution can be used after growing for 2 hours at room temperature and protected from light.

[0057] Growth medium preparation method: Add 40mL 0.1M CTAB solution, 400μL 0.01MAgNO to a 50mL plastic centrifuge tube 3 solution, 2 mL 0.01M HAuCl 4 Solution, 800μL 1.0M HCl solution, after mixing evenly, the solution turns orange. Then, 320 μL of 0.1 M ascorbic acid (AA) solution was added to the mixed solution, and a colorless transparent solution was obtained after gently shaking to obtain a gold nanorod growth solution.

[0058] Preparation of gold nanorods: Add 15 µL of go...

Embodiment 2

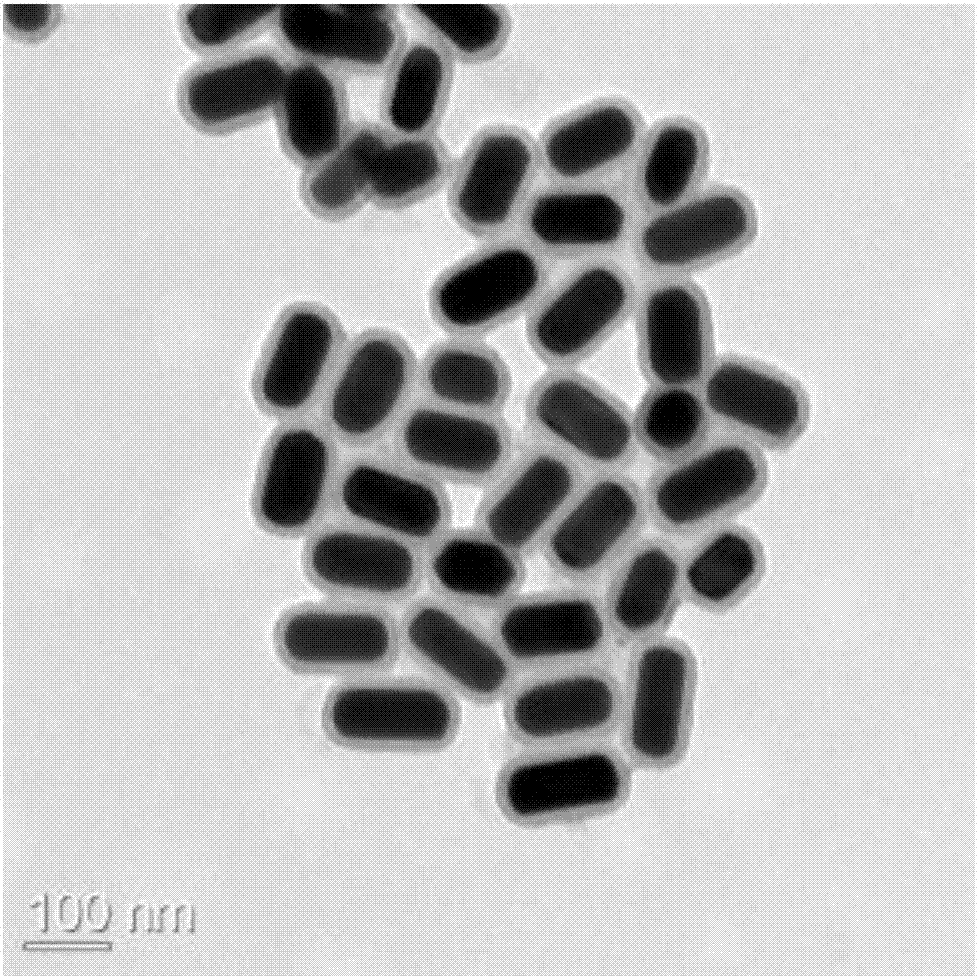

[0068] The difference is that the volume of the ethanol solution of TEOS added in step (3) is 30 μL, and the reaction is carried out for at least 2 hours under shaking conditions, and the Au NR / SiO with a silicon dioxide thickness of about 13 nanometers is prepared. 2 Composite nanomaterial sample; step (4) high temperature treatment at 600° C. for 5 hours, other steps are the same as in Example 1.

Embodiment 3

[0070] The difference is that the volume of the ethanol solution of TEOS added in step (3) is 40 μL, and the reaction is carried out for at least 2 hours under shaking conditions, and Au NR / SiO with a silicon dioxide thickness of about 20 nanometers is prepared. 2 Composite nanomaterial sample; step (4) high temperature treatment at 600° C. for 4 hours, other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com