Method for preparing tobacco flavor

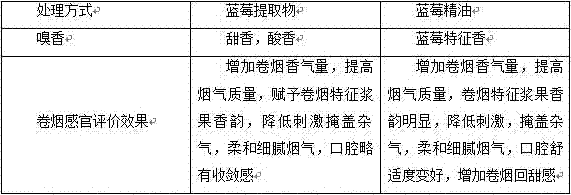

A technology of tobacco spices and glucosidase, applied in the field of tobacco, can solve the problems of inconspicuous blueberry aroma and loss of aroma substances, etc., and achieve the effects of good cigarette application effect, reducing stimulation, and covering up miscellaneous gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Take a certain amount of fresh blueberries, wash them, squeeze the juice, and collect the juice;

[0019] (2) Immobilization of β-glucosidase: Prepare a mixed solution containing 6% by mass polyvinyl alcohol and 1% by mass sodium alginate, and then add 1% by mass β-glucoside to the mixed solution Enzyme, drop FeCl with a mass concentration of 5 g / L and a pH value of 2 with a syringe 3 Cross-link in the solution for 9 hours, rinse with a large amount of distilled water, add distilled water for desalination for 2 hours, and finally obtain PVA.SA-Fe gel balls, dry them for later use;

[0020] (3) Use the immobilized β-glucosidase prepared in step (2) to treat the blueberry juice, the solid dosage of the immobilized β-glucosidase is 2 g / L, the pH value of the enzyme treatment is 4, the enzyme treatment temperature is 30°C, and the enzyme treatment time 10h;

[0021] (4) PEI pervaporation membrane was selected. After the treatment in step (3), the blueberry juice was s...

Embodiment 2

[0023] (1) Take a certain amount of fresh blueberries, wash them, squeeze the juice, and collect the juice;

[0024] (2) Immobilization of β-glucosidase: Prepare a mixed solution containing 8 mass percent polyvinyl alcohol and 2 mass percent sodium alginate, and then add 1 percent β-glucoside to the mixed solution Enzyme, use a syringe to drop into the FeCl3 solution with a mass concentration of 5g / L and a pH value of 2 to crosslink for 12 hours, rinse with a large amount of distilled water, and then add distilled water for desalination for 2 hours, and finally obtain PVA.SA-Fe gel balls, dry for later use;

[0025] (3) Use the immobilized β-glucosidase prepared in step (2) to treat the blueberry juice, the solid dosage of the immobilized β-glucosidase is 2 g / L, the pH value of the enzyme treatment is 5, the enzyme treatment temperature is 35°C, and the enzyme treatment Time 15h;

[0026] (4) PEI pervaporation membrane was selected. After the treatment in step (3), the blueb...

Embodiment 3

[0028] (1) Take a certain amount of fresh blueberries, wash them, squeeze the juice, and collect the juice;

[0029] (2) Immobilization of β-glucosidase: Prepare a mixed solution containing 8% by mass of polyvinyl alcohol and 2% by mass of sodium alginate, and then add 1.5% by mass of β-glucoside to the mixed solution Enzyme, use a syringe to drip into FeCl3 solution with a mass concentration of 5 g / L and a pH value of 2 for cross-linking for 12 hours, rinse with a large amount of distilled water, and then add distilled water for desalination for 3 h, and finally obtain PVA.SA-Fe gel balls , dry for later use;

[0030] (3) Use the immobilized β-glucosidase prepared in step (2) to treat the blueberry juice, the solid dosage of the immobilized β-glucosidase is 4 g / L, the pH value of the enzyme treatment is 5, the enzyme treatment temperature is 35°C, and the enzyme treatment time 20 h;

[0031] (4) PEI pervaporation membrane was selected. After the treatment in step (3), blueb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com