UVLED high-intensity line light source

A line light source and high-intensity technology, applied in the field of optical engineering, can solve the problems of high power consumption, ozone generation, and high heat generation, and achieve the effects of long life, less heat generation, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

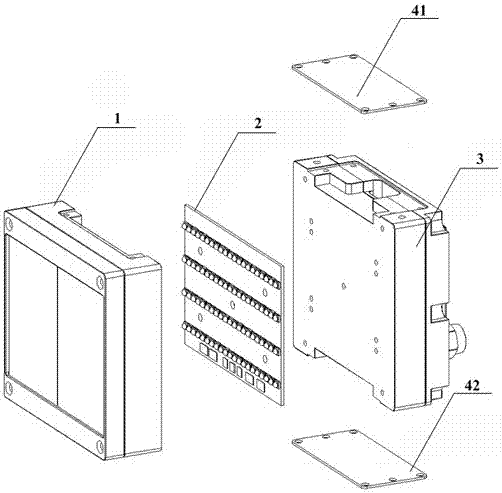

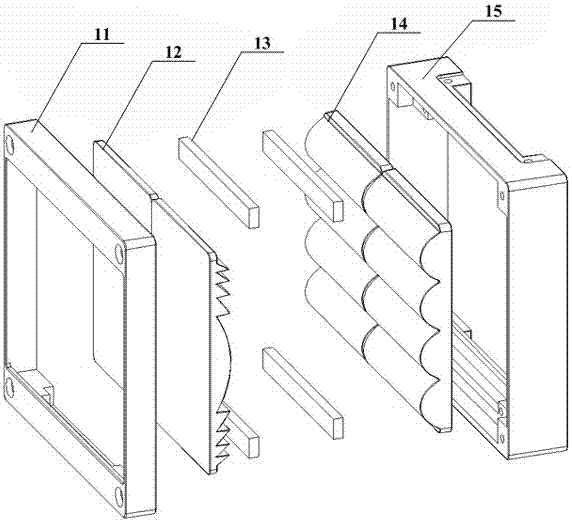

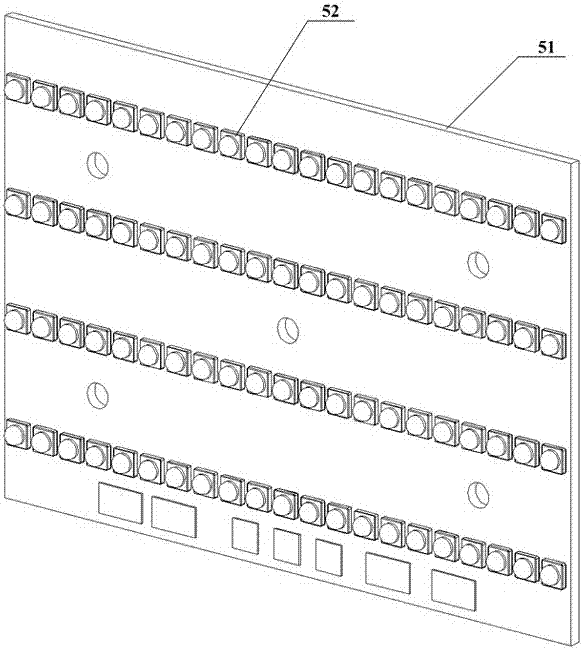

[0044] Such as figure 1 , shown in 2, 3, and 4, the UVLED high-intensity line light source includes an optical concentrating system 1, a UVLED array light emitting system 2 and a water cooling system 3, and the UVLED array light emitting system 2 is installed on the optical concentrating system 1 and Between the water-cooling heat dissipation systems 3; the optical focusing system 1 includes a shaping lens 14, a focusing lens 12 and at least two lens mounts, the shaping lens 14 is installed on the first lens mounting frame 15, and the The condenser lens 12 is installed on the second lens mounting frame 11; the UVLED array lighting system 2 includes a substrate 51 and UVLED lamp beads 52, and the UVLED lamp beads 52 are mounted on the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com