Strain loading system for micro-nano material multi-field joint characterization

A technology of micro-nano materials and loading systems, which is applied in the fields of analysis materials, measuring devices, instruments, etc., can solve the problems that cannot meet the requirements of micro-nano material elastic strain engineering research, the difficulty of testing the electrical properties of target materials, and the difficulty of applying strain with low precision, etc. problem, to achieve the effect of simple structure, improved universality and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

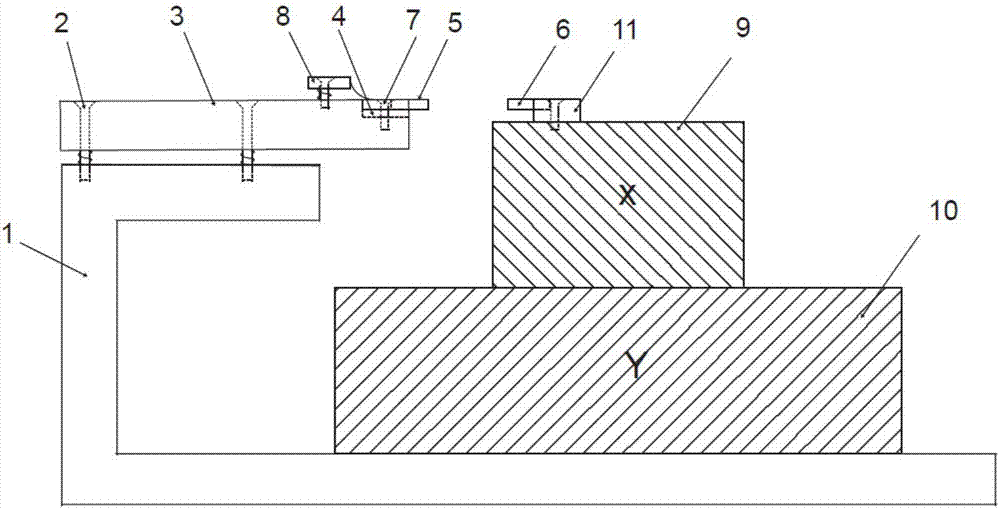

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

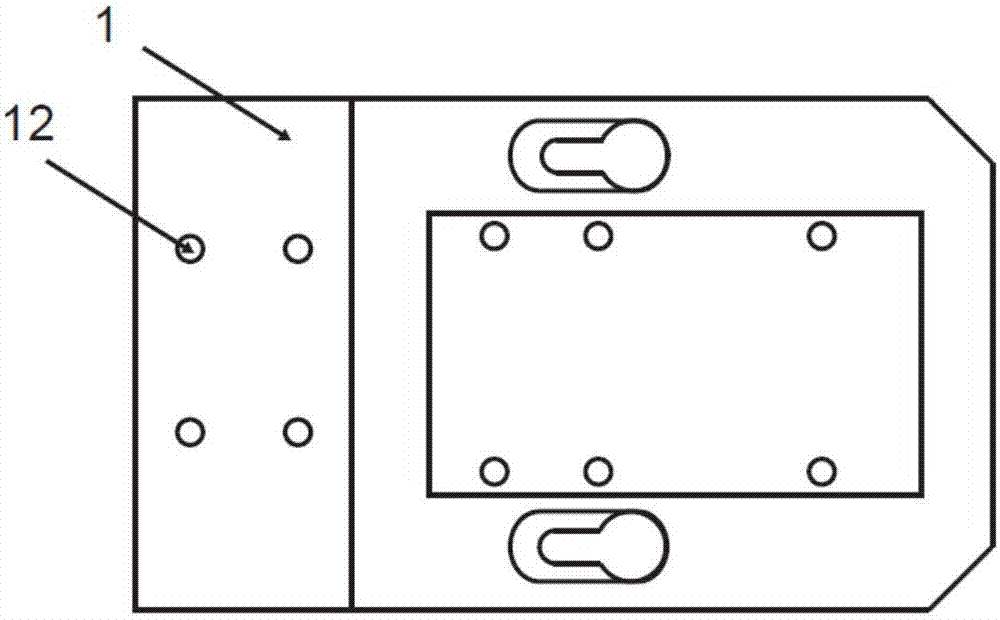

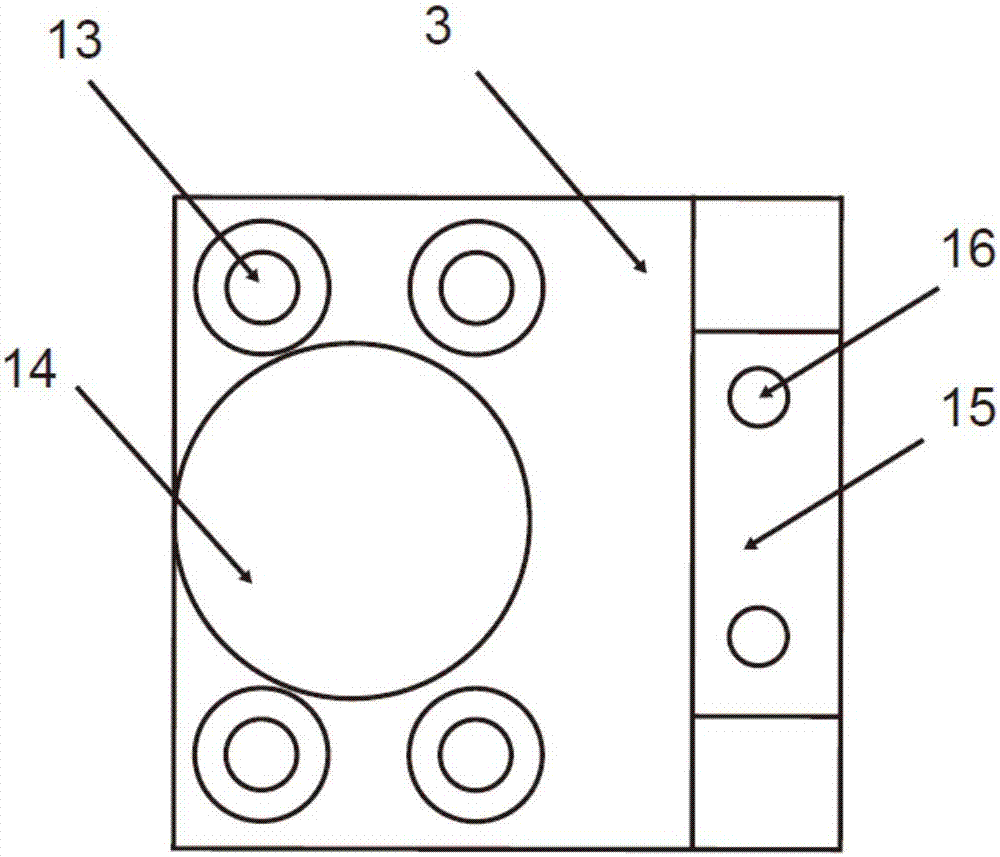

[0029] refer to figure 1 , 2 , a strain loading system for multi-field joint characterization of micro-nano materials according to the present invention includes a substrate 1, a sample stage 3, an electrode pressing piece 8, a metal support 7, a loading stage 5, an indenter 6, and a piezoelectric ceramic 8 And piezoelectric ceramic 9, spring screw 2, set screw 4. The sample stage 3 is fixed on the uppermost end of the base body 1 by the spring screw 2 through the counterbore 13, and the height of the sample stage 3 can be adjusted by adjusting the screwing depth of the spring screw 2. The sample stage 3 has a level 14, which can observe whether the sample stage 3 is whole Keep, ensure that the sample stage 3 remains horizontal after adjusting the depth of the screw, the piezoelectric ceramic 9 and the piezoelectric ceramic 10 are fixed to each other, the piezoelect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com