Electric energy meter wiring electric corrosion prevention pressing plate

An anti-electric corrosion and electric energy meter technology, applied in the measurement of electrical variables, measuring devices, instruments, etc., can solve the problems of contact overheating, increased contact resistance of contacts, and electrical corrosion, so as to reduce contact heating, reduce contact resistance, The effect of increasing the connection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

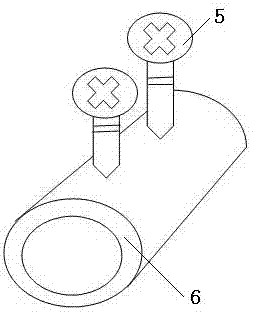

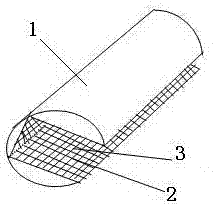

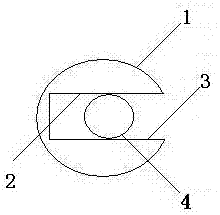

[0011] see figure 1 , 2 , 3. The names of the parts are as follows: cylindrical body 1, opening 2, spiral pattern 3, wire 4, locking screw 5, and electric energy meter terminal 6.

[0012] see figure 1 , 2 3. The anti-corrosion pressure plate for electric energy meter wiring includes a cylindrical body 1, openings 2 in the middle and one side, and spiral patterns 3 on the upper and lower sides of the opening 2. The whole is tin-plated. For example, the cylindrical body 1 has an outer diameter of 9.6mm, a length of 17mm, and an opening height of 4mm, which is suitable for a wire with an outer diameter of 3mm and 4mm. The whole is tin-plated, and tin or zinc is used for material transition to solve the problem of electric corrosion. The pressure plate is cylindrical, with an opening in the middle, with spiral threads inside (to ensure tight crimping), and the outer tin or zinc plating of copper is used to solve the problem of copper-aluminum transition and copper-iron tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com