Thin film transistor, display substrate, method for fabricating the same and display device

A technology of thin film transistor and manufacturing method, which is applied in transistor, semiconductor/solid-state device manufacturing, semiconductor device and other directions, can solve problems such as poor process, high production cost, poor conductivity, etc., to avoid IRDrop phenomenon, ensure conductivity, The effect of improving the display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

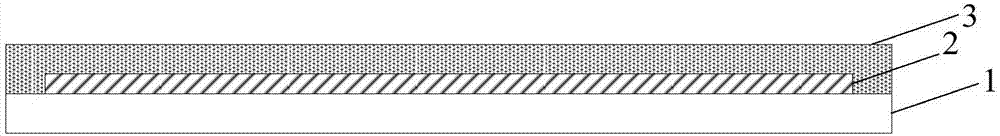

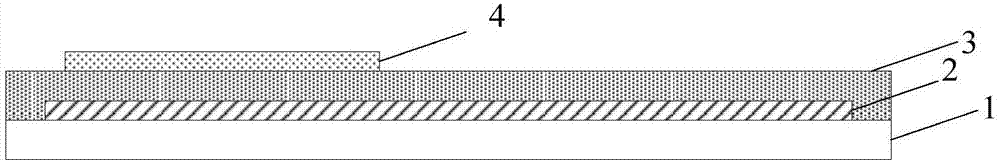

[0043] like Figure 1-Figure 8 As shown, the prior art generally requires 7-8 patterning processes to fabricate a top-gate TFT display substrate. Specifically, the existing method for fabricating a top-gate TFT display substrate includes the following steps:

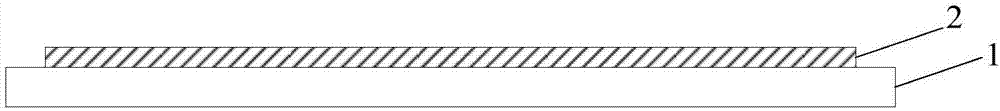

[0044] Step 1, such as figure 1 As shown, a base substrate 1 is provided, and a light-shielding metal pattern 2 is formed on the base substrate 1;

[0045] Wherein, the base substrate 1 may be a glass substrate or a quartz substrate. A metal layer can be deposited on the base substrate 1 by sputtering or thermal evaporation, and the metal layer is patterned to form a light-shielding metal pattern 2. The metal layer can be Cu, Al, Ag, Mo, Cr, Nd, Ni, Metals such as Mn, Ti, Ta, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com