Purifying method for ultra-pure hydrogen, argon and helium

A purification method and hydrogen technology, applied in chemical instruments and methods, inert gas compounds, hydrogen/synthesis gas production, etc., can solve problems affecting the production of devices in the electronics industry, and the quality of electronic components declines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

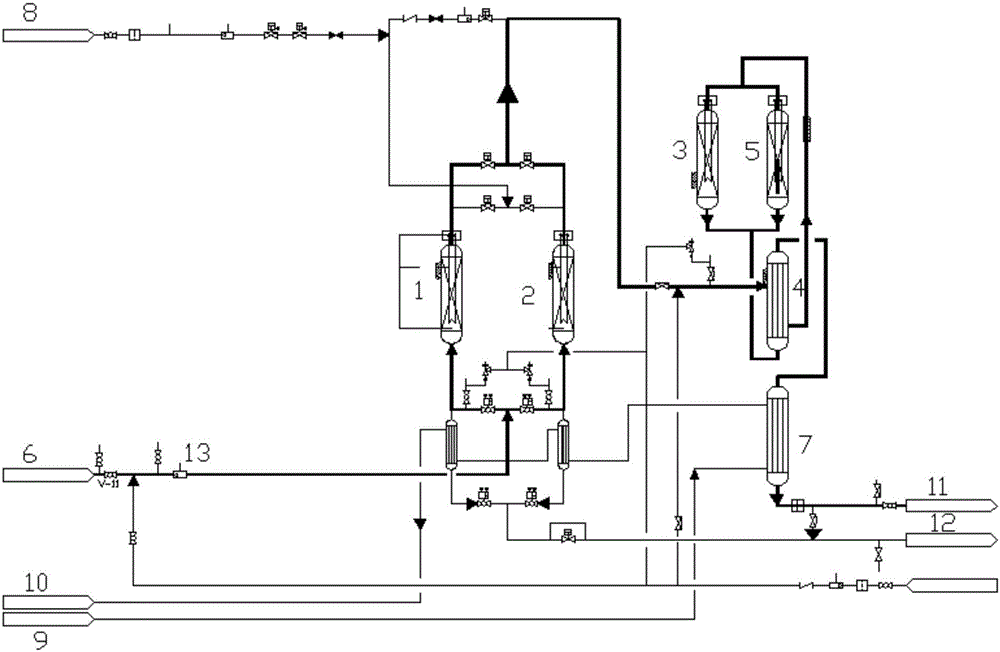

[0017] The present invention will be further described below in conjunction with accompanying drawing:

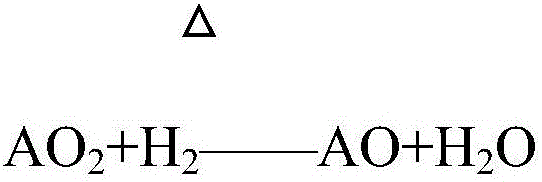

[0018] Such as figure 1 As shown, a method for purifying ultra-high-purity hydrogen, argon, and helium includes a drying and deoxidizing process, an air intake process, and a regeneration process; the dry and deoxidizing process is as follows: the raw material gas enters the adsorption dryer through the raw material gas inlet 6, O in raw gas 2 React with the reduced deoxidizer in the adsorption dryer, and the reduced deoxidizer absorbs H in the feed gas at the same time 2 O.CO 2 ; The adsorption drier includes an adsorption drier A1 and an adsorption drier B2, and the adsorption drier A1 and the adsorption drier B2 circulate gas adsorption and regeneration, and both the adsorption drier A1 and the adsorption drier B2 are equipped with There are temperature sensors, electric heaters, and heat storage mechanisms; the suction process is as follows: the raw material gas that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com